Efficient cooling and sampling device

A sampling device and high-efficiency technology, used in sampling devices, heat exchange equipment, fixed tubular conduit components, etc., can solve the problems of poor heat conduction effect on the outer wall of the cooling pipe, scalding people caused by overheated gas, and poor cooling effect of the cooling barrel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

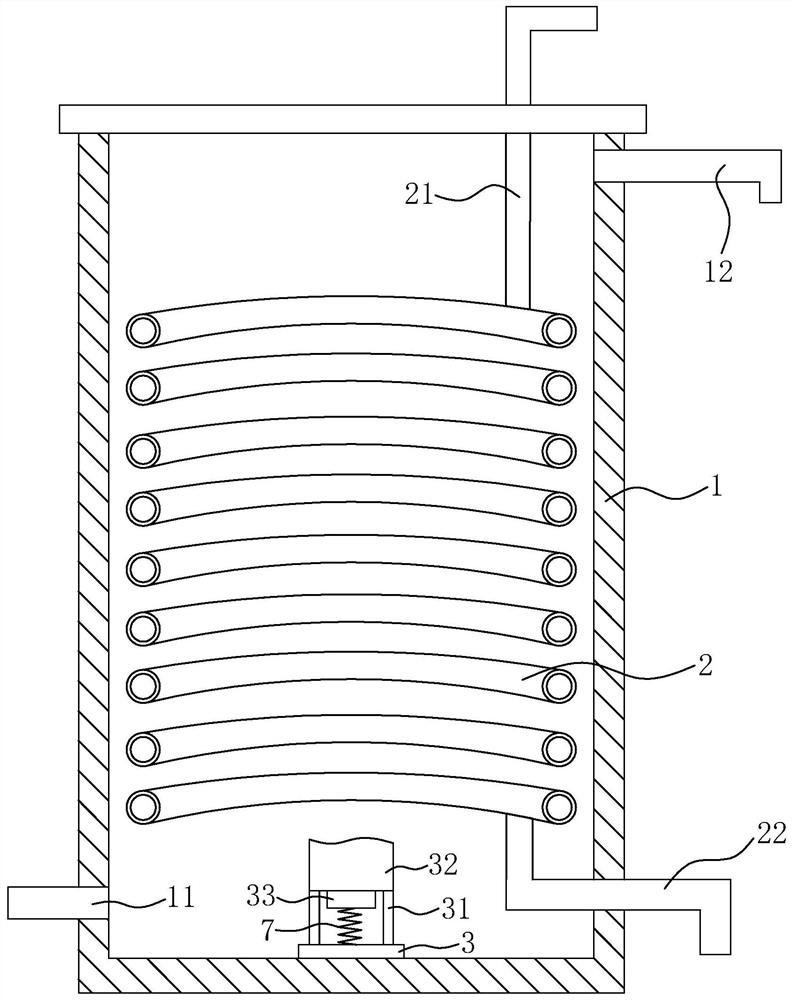

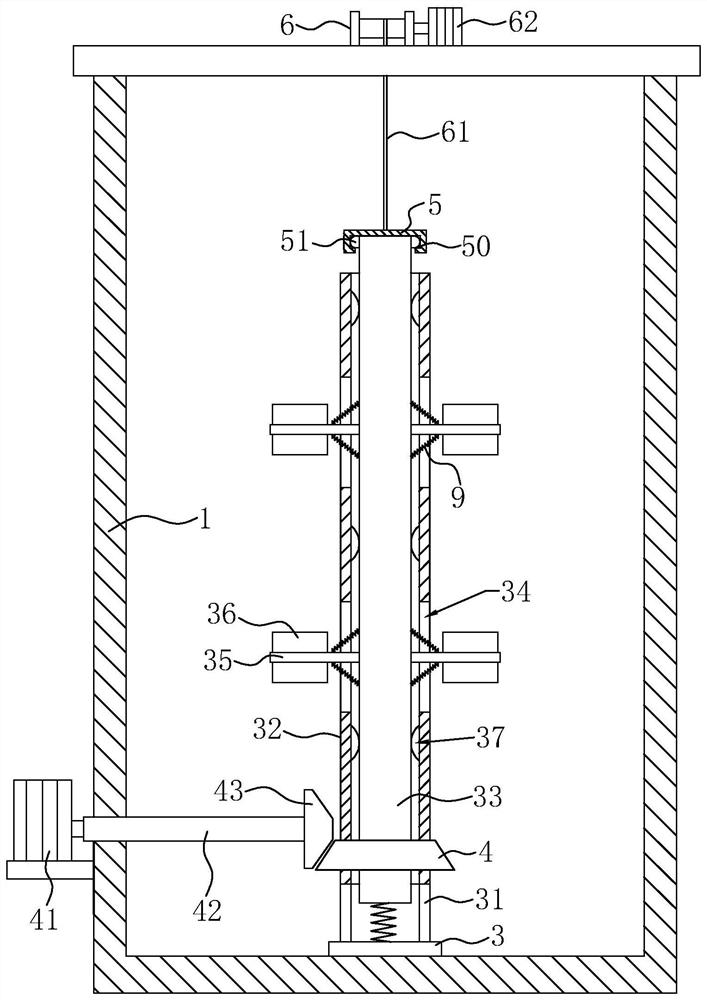

[0035] Embodiment 1: a kind of efficient cooling sampling device, such as figure 1 and figure 2 As shown, a water inlet 11 is provided at the bottom of the cooling barrel 1, and a water outlet 12 is provided at the top of the cooling barrel 1, so that the cooling barrel 1 can store cooling water; and a cooling pipeline is installed inside the cooling barrel 1 2. The cooling pipe 2 is spirally arranged vertically inside the cooling barrel 1, and the cooling pipe 2 is provided with a water inlet 21 and a sampling port 22. When sampling is required, the water inlet 21 of the cooling pipe 2 can be connected with the sample liquid , so that the sample liquid is cooled along the cooling pipe 2, and after the sample liquid is cooled by the cooling water in the cooling barrel 1, it can be discharged from the sampling port 22, and then the subsequent sample liquid detection is performed.

[0036] A turntable 3 is installed on the inner wall of the bottom of the cooling barrel body 1,...

Embodiment 2

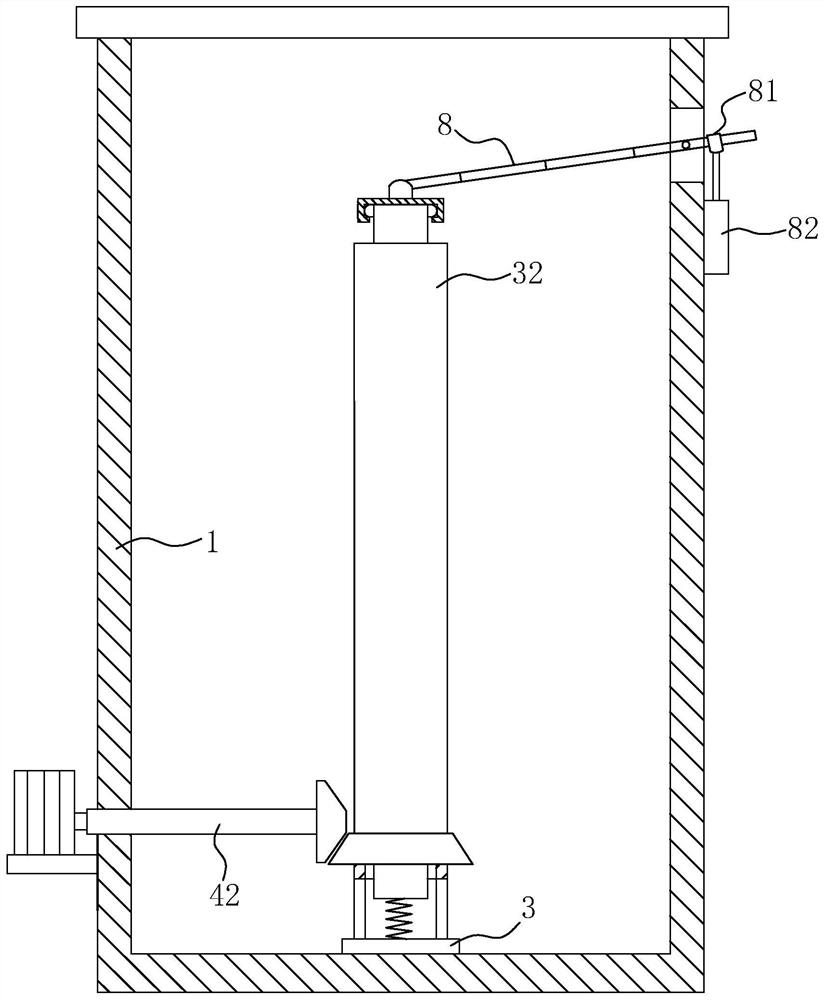

[0047] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 lies in the difference of the lifter. In this embodiment, the lifter includes one end hinged on the top of the connecting block 5, and the other end horizontally passing through the telescopic rod 8 of the cooling barrel 1; The collar 81 on the telescoping rod 8 passes through the end; Then vertically be provided with the strip mouth that passes for telescopic rod 8, and telescopic rod 8 is hinged on the inwall of strip mouth.

[0048] When the cylinder 82 is opened, the piston rod of the cylinder 82 can drive the telescopic rod 8 to shake up and down, so that the telescopic rod 8 can rotate around the position of the strip opening, and the telescopic rod 8 can drive the connecting block 5 to lift up and down during the rotation process, thereby Drive the movable rod 33 to lift, and through this solution, the stirring blade 36 can also be driven to lift to realize the stirring of the cooling water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com