Eddy-current damping wall and building

An eddy current damping and eddy current technology, applied in buildings, building components, building types, etc., can solve problems such as affecting the use function of the damping wall, high maintenance and repair costs, and inability to increase structural rigidity, and achieve low maintenance costs in the later period. Low maintenance cost and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

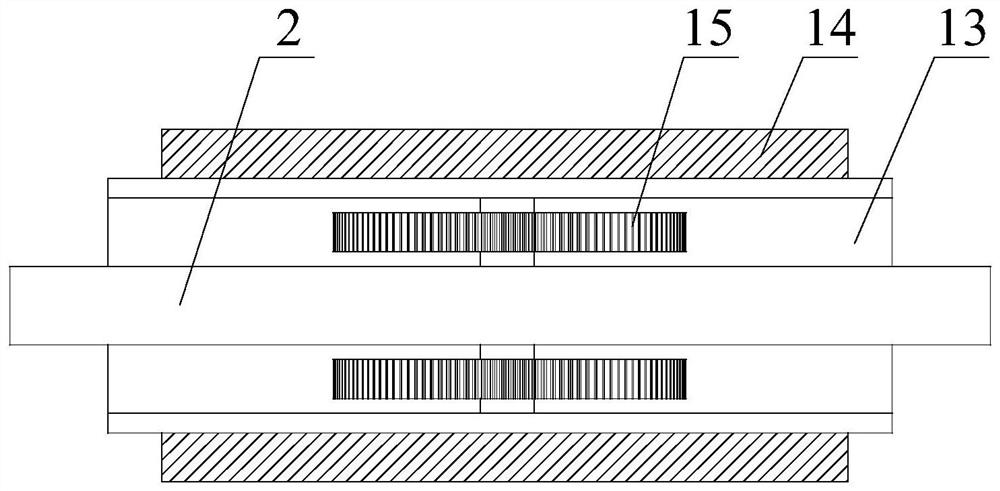

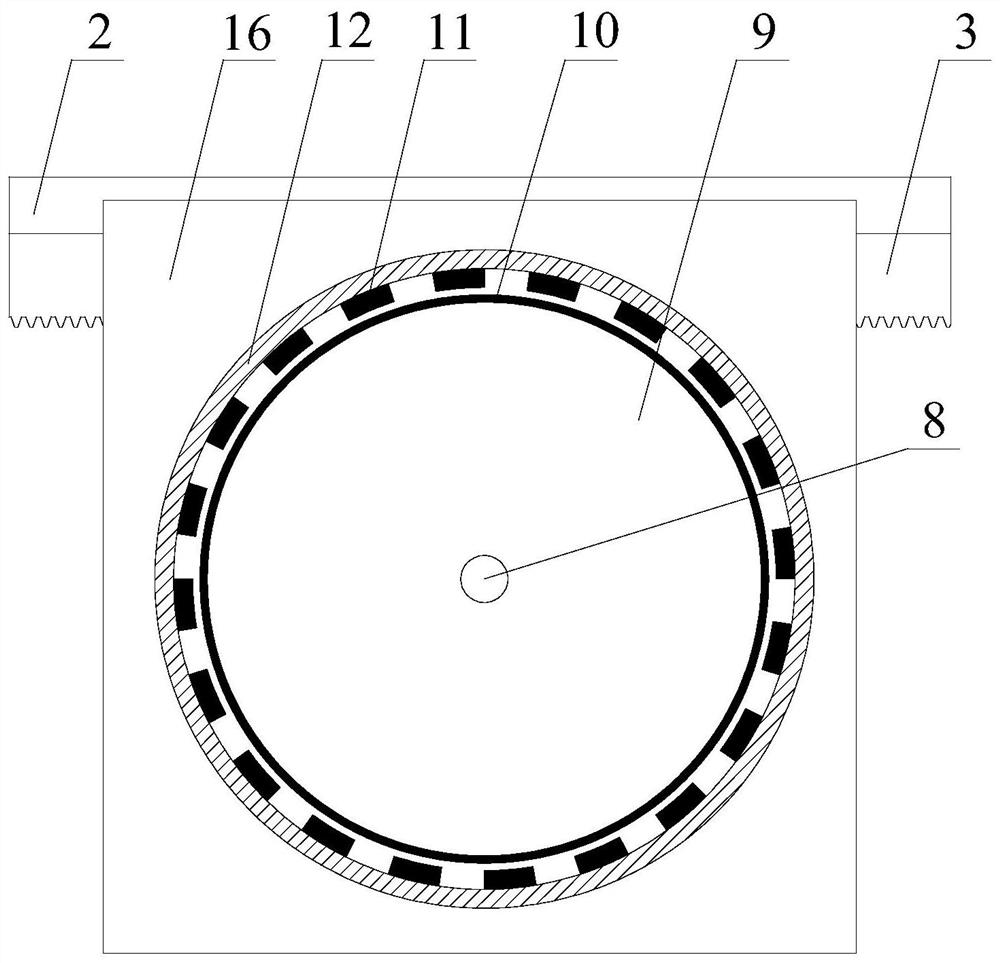

[0046] Such as Figure 1-3 As shown, a kind of eddy current damping wall described in this embodiment includes,

[0047] The first transmission shaft 8;

[0048] At least one eddy current assembly 14, the eddy current assembly 14 includes a conductor plate back iron 9 that is rotatably connected with the first transmission shaft 8, and the outside of the conductor plate back iron 9 is sequentially sleeved with a conductor plate 10 and a permanent magnet Back iron 12, the inner wall of the permanent magnet back iron 12 is provided with at least two permanent magnets 11, wherein at least two of the permanent magnets 11 are arranged at intervals along the inner wall of the permanent magnet back iron 12, and the permanent magnets 11 are generally set in pairs;

[0049]The transmission mechanism 15 is drivingly connected with the first transmission shaft 8, and the transmission mechanism 15 is used to convert the linear motion into the rotation of the first transmission shaft 8. ...

Embodiment 2

[0057] Such as Figure 4 As shown, a building with an eddy current damping wall described in this embodiment includes a kind of eddy current damping wall as described in Embodiment 1 and a substructure 17 connected to the side plate 16, and The rack 3 is connected to the superstructure 1, and the substructure 17 is generally a floor or a beam below the side plate 16; the superstructure 1 is generally a floor or a beam above the rack 3;

[0058] When in use, the lower building structure 17 is connected to the side plate 16 for supporting the rigid frame 13, and the upper building structure 1 is connected to the rack 3, so that the rack 3 can connect the upper building structure 1 The linear motion also includes some slight swings converted into the rotation of the first transmission shaft 8, the first transmission shaft 8 drives the conductor plate back iron 9 and the conductor plate 10 to cut the magnetic field lines generated by the permanent magnet 11, and then the conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com