Water discharging device

A technology of water outlet device and water outlet hole, which is applied in the field of sanitary ware, and can solve the problem of less water outlet function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] This embodiment is suitable for a kitchen faucet with an external thread or a bathroom faucet with an external thread.

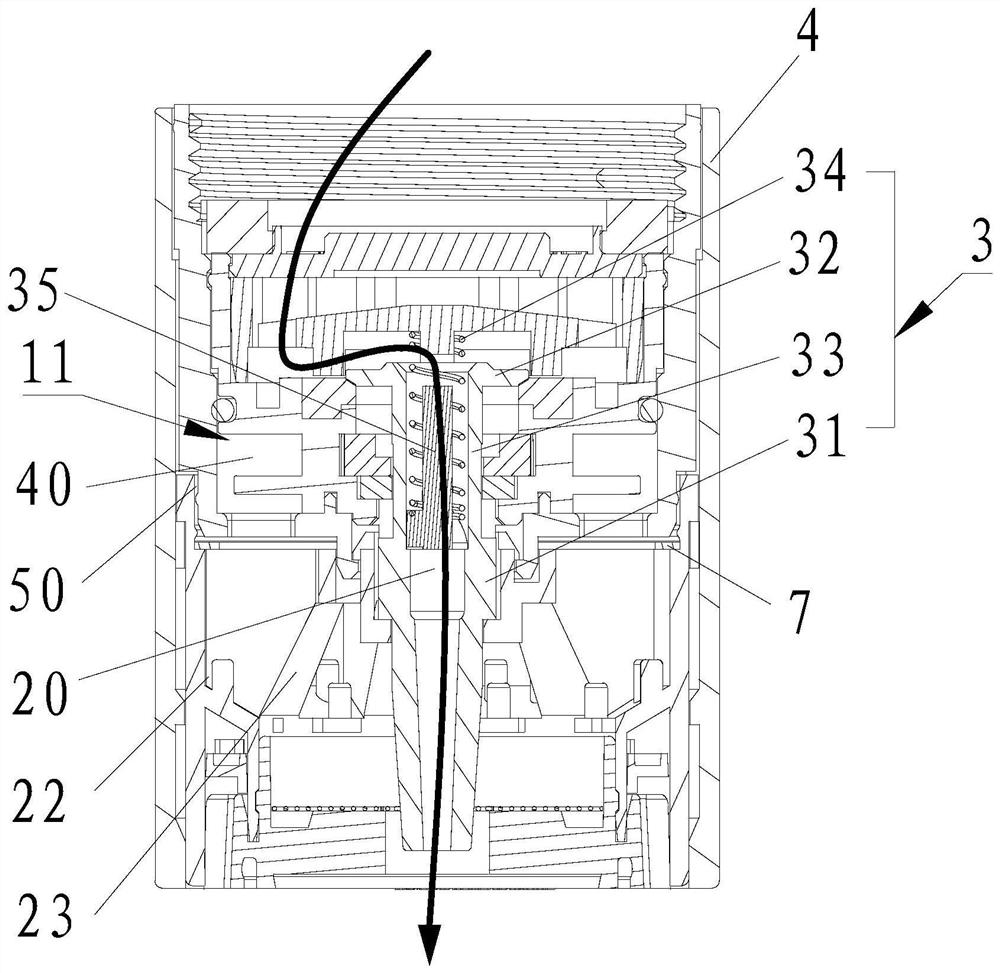

[0103] Please refer to Figure 1-Figure 7 , a water outlet device, comprising a water inlet mechanism 1, a diversion mechanism 2 connected to the water inlet mechanism 1, and a diversion mechanism 3 installed in the water inlet mechanism 1 and passing through the diversion mechanism 2;

[0104] The water inlet mechanism 1 includes a water inlet channel 10;

[0105] The flow diversion mechanism 3 includes a first water outlet channel 20;

[0106] The flow guide mechanism 2 includes a second water outlet channel 301 and a third water outlet channel 302;

[0107] When the flow guide mechanism 2 is moving relative to the flow diversion mechanism 3 , the water inlet channel 10 communicates with the first water outlet channel 20 , the second water outlet channel 301 or the third water outlet channel 302 .

[0108] refer to Figure 8 , there is also a mo...

Embodiment 2

[0132] The difference between this embodiment and the first embodiment is that the specific structure of the water inlet assembly 11 is limited.

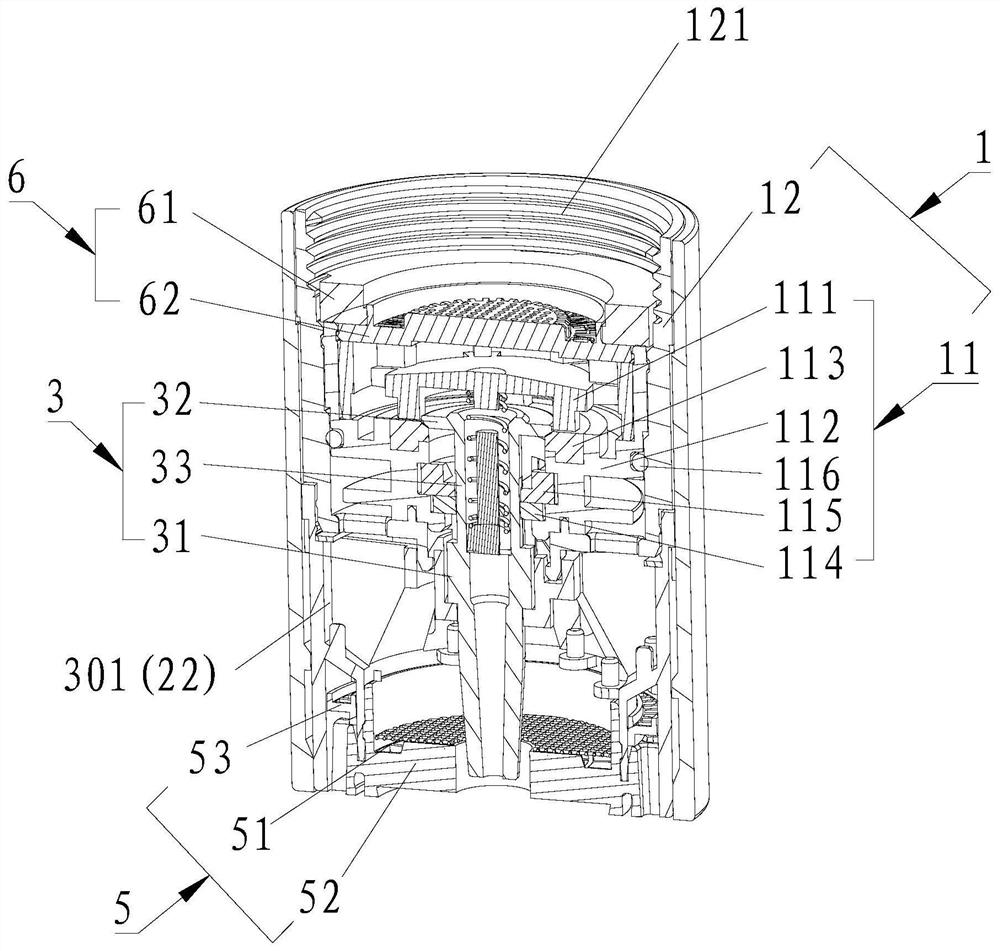

[0133] Please refer to figure 2 , the water inlet assembly 11 includes an upper water inlet ring 111, a lower water inlet ring 112, a second gasket 113, a third gasket 114, a buckle 115 and a fourth gasket 116; the second gasket 113 is embedded on the top of the lower water inlet ring 112 , the upper water inlet ring 111 is embedded in the top of the lower water inlet ring 112; the buckle 115 is horizontally inserted in the water outlet of the lower water inlet ring 112, and the third gasket 114 is embedded in the lower water inlet ring 112 and is located on the buckle Below 115; the water outlet assembly 12 is sleeved outside the lower water inlet ring 112; the fourth gasket 116 is sleeved outside the lower water inlet ring 112 and inside the water outlet assembly 12; the upper ends of the two protrusions 31 are sandwiched between...

Embodiment 3

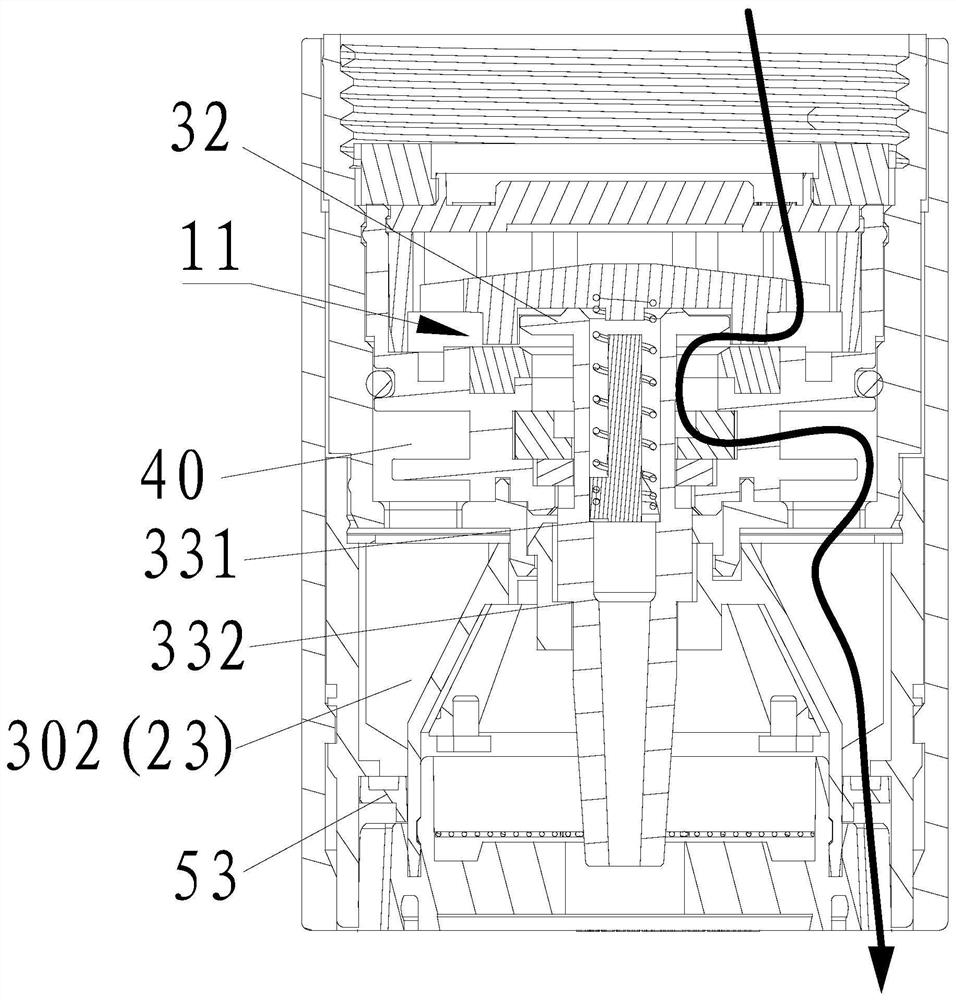

[0136] The difference between this embodiment and the second embodiment is that the second structure of the flow guide mechanism 2 and the flow diversion mechanism 3 is defined.

[0137] refer to Figure 9-Figure 12 , a second annular boss 36 is arranged on the outside of the diverter mechanism 3, and a trapezoidal groove 361 is opened on the lower side of the second annular boss 36 to form two stepped surfaces of different heights, namely the first stepped surface 3611 and the second stepped surface 3612 , the first stepped surface 3611 is located at the bottom of the second annular boss 36 , and the second stepped surface 3612 is located at the top of the trapezoidal groove 361 . The top width of the trapezoidal groove 361 in the rotation direction is smaller than the bottom width of the trapezoidal groove 361 in the rotation direction. The outside of the flow diversion mechanism 3 is also provided with two opposite protrusions 31. The protrusions 31 are inserted at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com