Roller forming device for highway construction

A rolling forming, road technology, applied in the direction of road, road, road repair, etc., can solve the problems of steering trouble, pressing device without steering mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

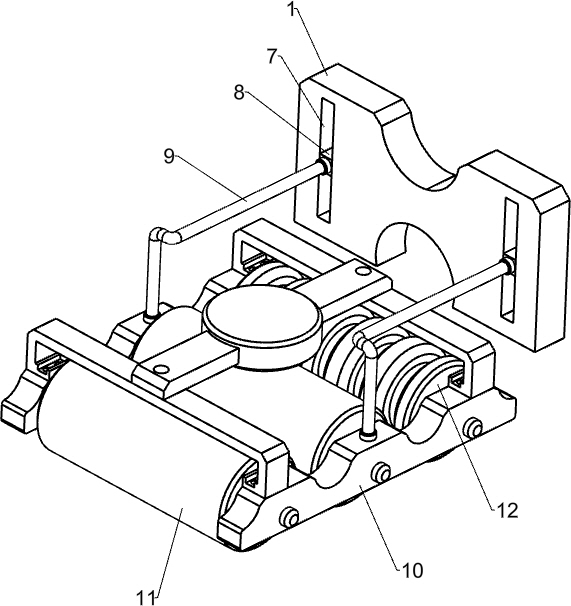

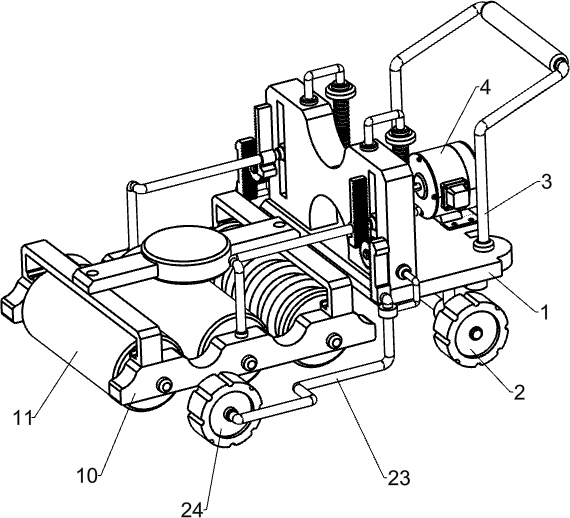

[0022] A road construction roll forming device, such as Figure 1-4 As shown, it includes a base plate 1, a first roller 2, a handle 3, a driving assembly, a rolling assembly and a lifting assembly. The lower end of the base plate 1 is symmetrically rotated with the first roller 2, and the right side of the base plate 1 is fixed by bolts. There is a handle 3, the right side of the base plate 1 is provided with a drive assembly powered by a motor, the left side of the base plate 1 is provided with a rolling assembly that rolls the road surface by rolling, and the middle of the base plate 1 is provided with a rolling assembly that rotates to make the road surface roll. A lifting component that lifts components up and down.

[0023] When the device is used for road rolling forming work, the driving component is controlled to work, and the lifting component is driven to rotate, so that the rolling component is lowered. When the bottom of the rolling component is close to the groun...

Embodiment 2

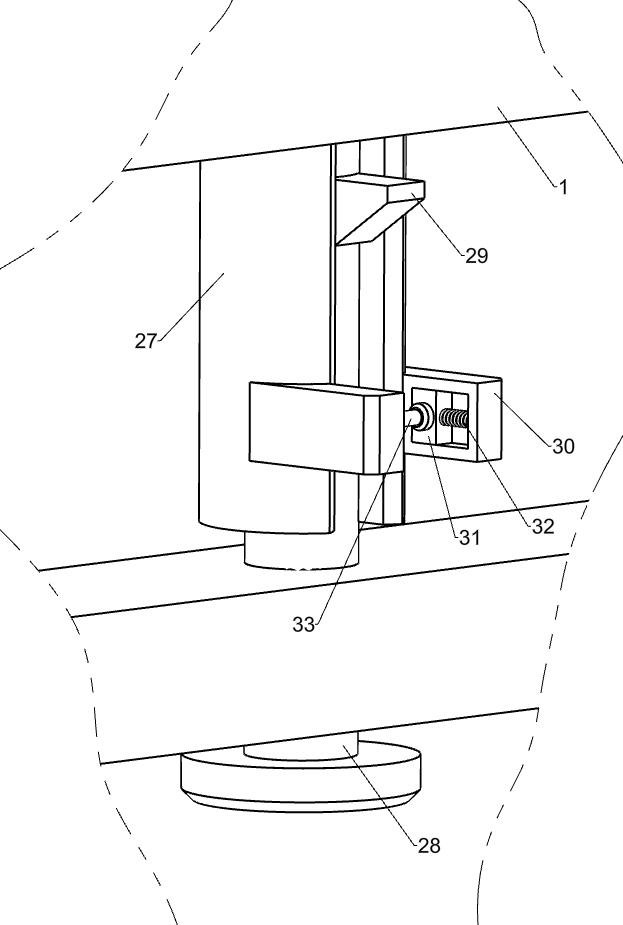

[0031] On the basis of Example 1, such as figure 1 , 5 Shown in and 6, also include the first tooth bar 21, guide sleeve 22, the second special-shaped bar 23, the second roller 24, the second tooth bar 25 and full gear 26, the first special-shaped bar 9 right parts are all fixed by bolts The first tooth bar 21 is connected, and the front and rear sides of the base plate 1 are fixedly connected with guide sleeves 22 by bolts. The second roller 24, the second special-shaped rod 23 right side tops are fixedly connected with the second rack 25 by bolts, and the left side of the base plate 1 is provided with a full gear 26 in a symmetrical rotation type before and after, and the full gear 26 is connected with the first rack 21 and the second rack 26. Two tooth racks 25 mesh.

[0032]In the process of controlling the downward movement of the rolling assembly, the downward movement of the first special-shaped rod 9 will drive the first rack 21 to move downward, causing the full gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com