Cotton scutching device based on ultrasonic washing technology

An ultrasonic and cotton cleaning technology, applied in the directions of fiber cleaning, fiber separation, textile and papermaking, etc., can solve the problems of cleaning, affecting cotton processing efficiency, affecting the quality of cotton textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

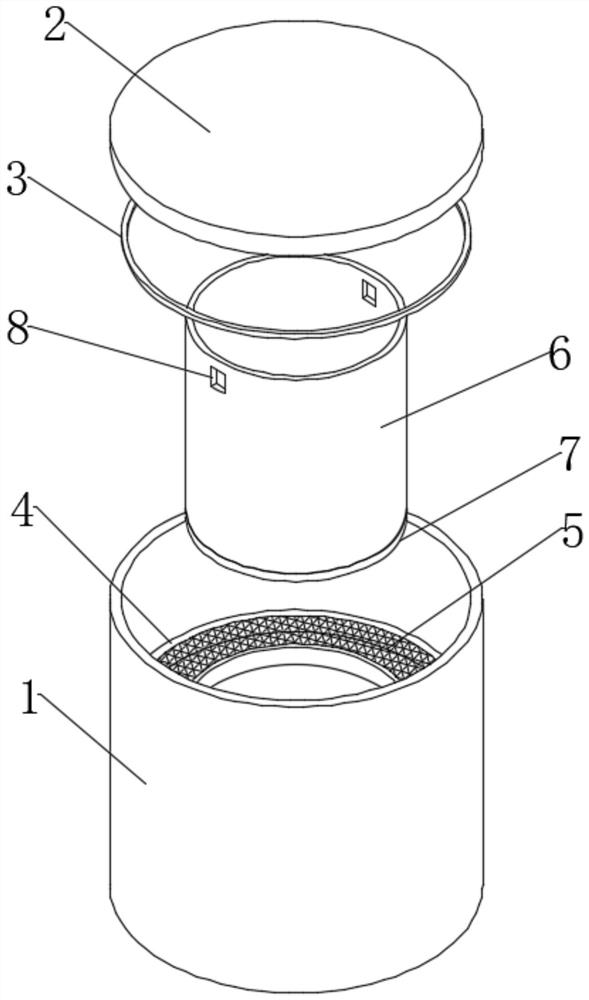

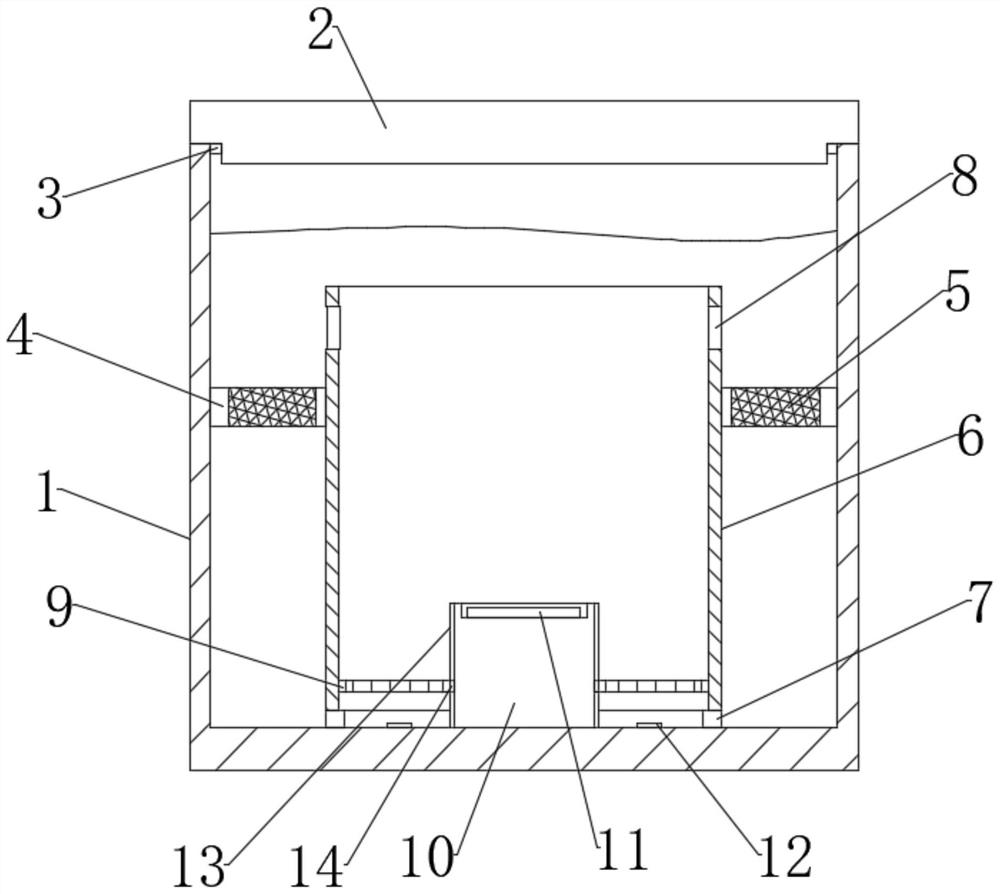

[0034] see Figure 1-5 , a cotton cleaning device based on ultrasonic cleaning technology, comprising a tank cover 2 of a main tank body 1 that matches each other, a sealing rubber ring 3 is connected between the main tank body 1 and the tank cover 2, and the sealing rubber ring 3 is connected to the tank The cover 2 is fixedly connected, the main tank body 1 is filled with cleaning liquid, and cotton fibers are put in the cleaning liquid, and the cotton fibers include long fibers and short fibers. The upper end is fixedly connected with an ultrasonic generating device 11, and the outer side of the installation platform 10 is sleeved with a cotton cleaning cylinder 6, and the groove bottom plate of the main tank body 1 is fixedly connected with a plurality of airflow nozzles 12, and the plurality of airflow nozzles 12 are all located on the outside of the cotton cleaning cylinder 6 , the side wall of the main tank body 1 is fixedly connected with a filter screen frame 4 matchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com