Cement flour unloading auxiliary device for straight column large plate

An auxiliary device, cement powder technology, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of excessive feeding speed and abnormal operation of the unloading cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

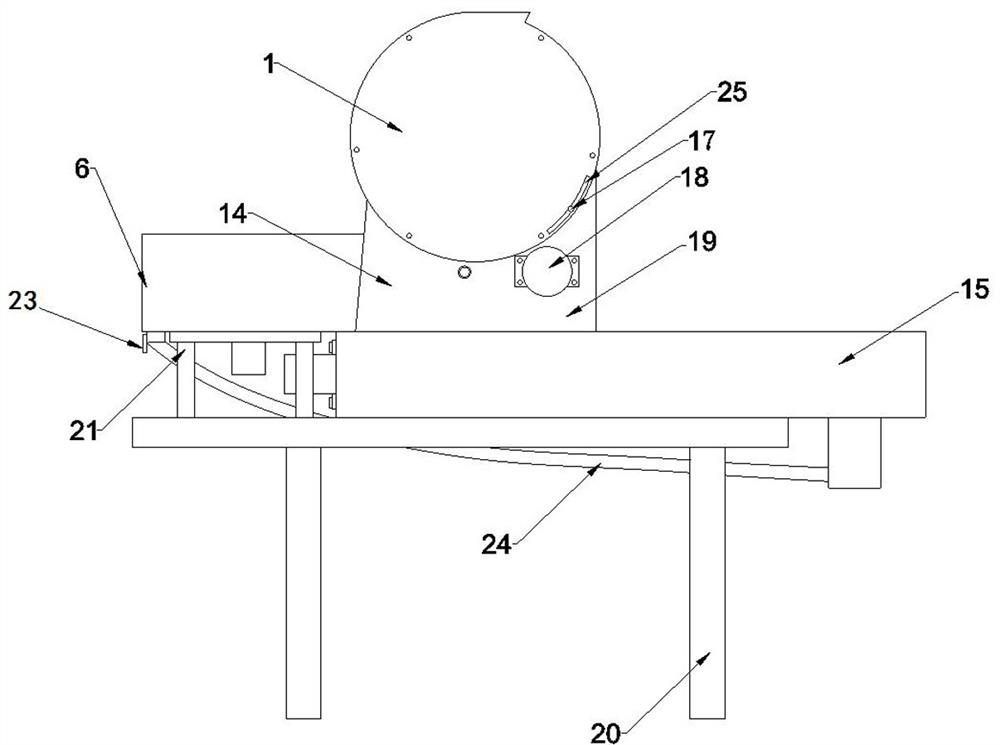

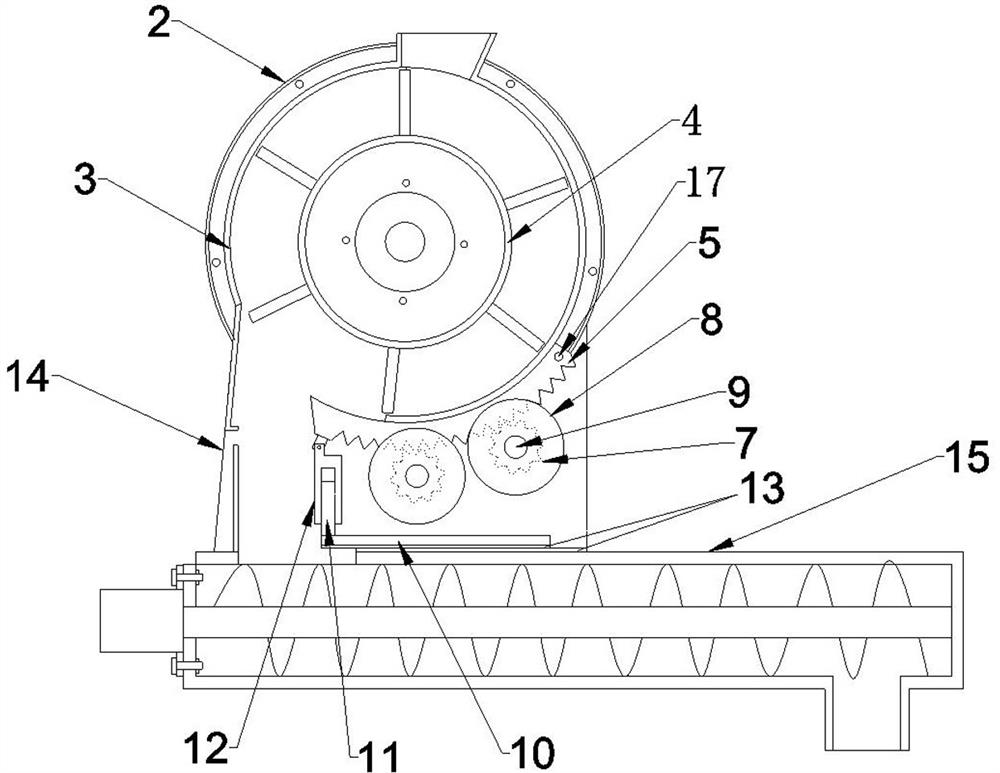

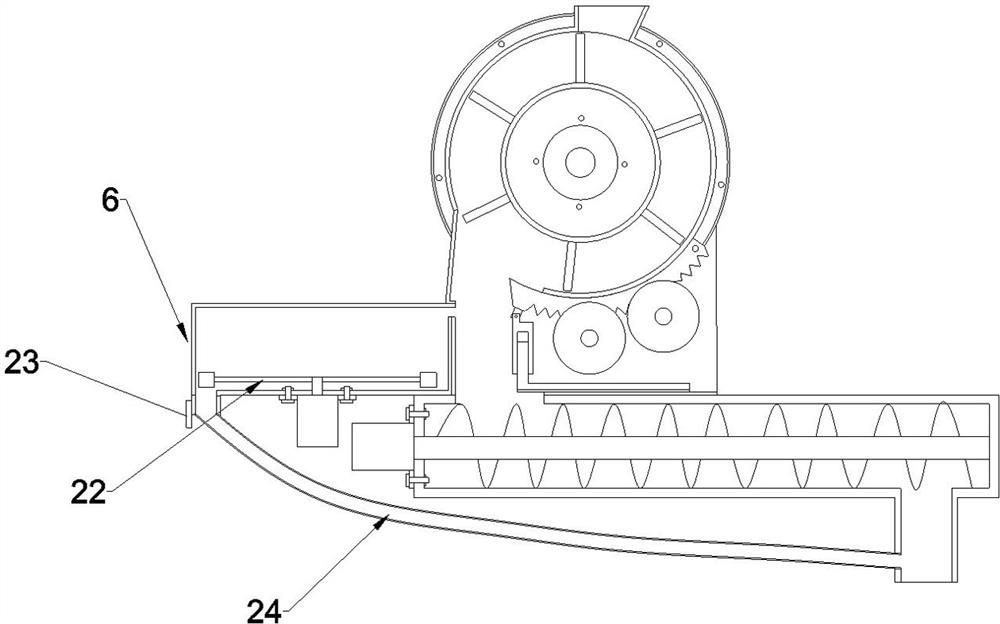

[0027] Such as Figure 1-4 The first embodiment of the present invention shown is a cement powder unloading auxiliary device for straight column slabs, including:

[0028] Horizontally placed discharge barrel 1, such as figure 2 As shown, the unloading cylinder 1 includes a circular shell-shaped outer cylinder 2 with both ends closed, and an inner cylinder 3 is fixed inside the outer cylinder 2. The inner cylinder 3 is a circular shell-shaped structure with circular baffles welded at both ends, and the baffles are fixed by bolts. The two ends of the outer cylinder 2 are installed inside the inner cylinder 3, and the star rotor 4 is installed. The star rotor 4 is composed of a hollow shaft with both ends closed and eight blades welded on the outer peripheral surface of the shaft. A gap is set, the central axes of the star rotor 4, the inner cylinder 2 and the outer cylinder 3 coincide, and the star rotor 4 is driven by the second motor. The top of the unloading barrel 5 is p...

Embodiment 2

[0037] Such as Figure 5 Shown is the second embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that a plurality of universal balls 16 are installed in a circumferential shape on the limiting plate 8, and the two universal balls 16 and the rack 5 The side phase contact reduces the frictional force suffered by the rack 5 when it slides, thereby reducing the load on the motor one 18 and prolonging the service life of the motor one 18 .

Embodiment 3

[0039] In order to save power consumption, the motor three can be started only when the cement powder starts to pile up quickly on the right side of the housing cylinder 6. The transparent glass is fixed on the hole by glue, and the transparent glass can completely cover the round hole to prevent the dust from overflowing from the round hole during stirring and pollute the surrounding environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com