Waterway structure of mold core

A technology of waterway structure and mold core, applied in the field of waterway structure, can solve the problems of increased mold processing time, mold core cracking and scrapping, and cooling efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical means and effects adopted by the present invention, a detailed description will be given below in conjunction with a preferred embodiment of the present invention and its accompanying drawings.

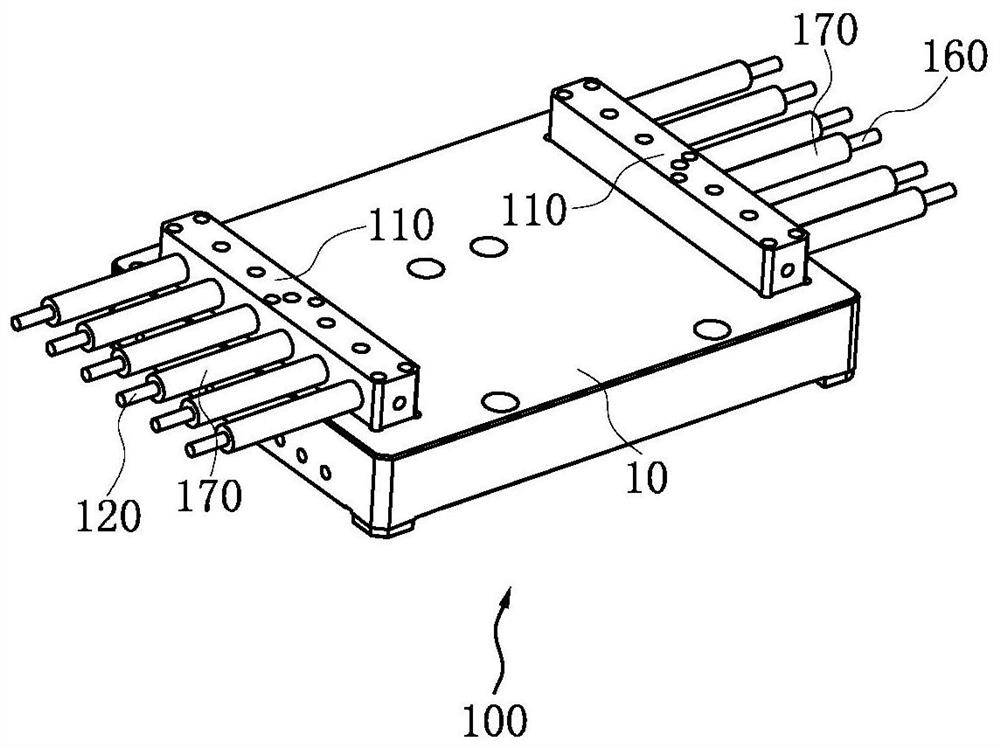

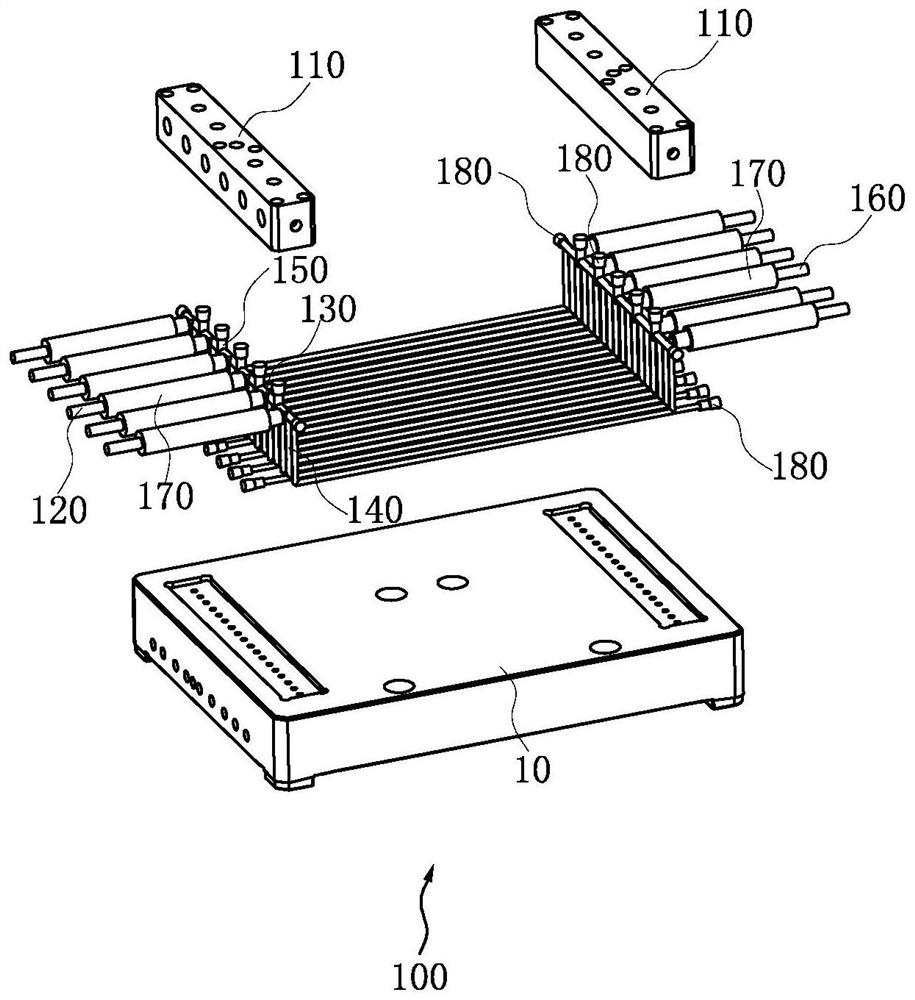

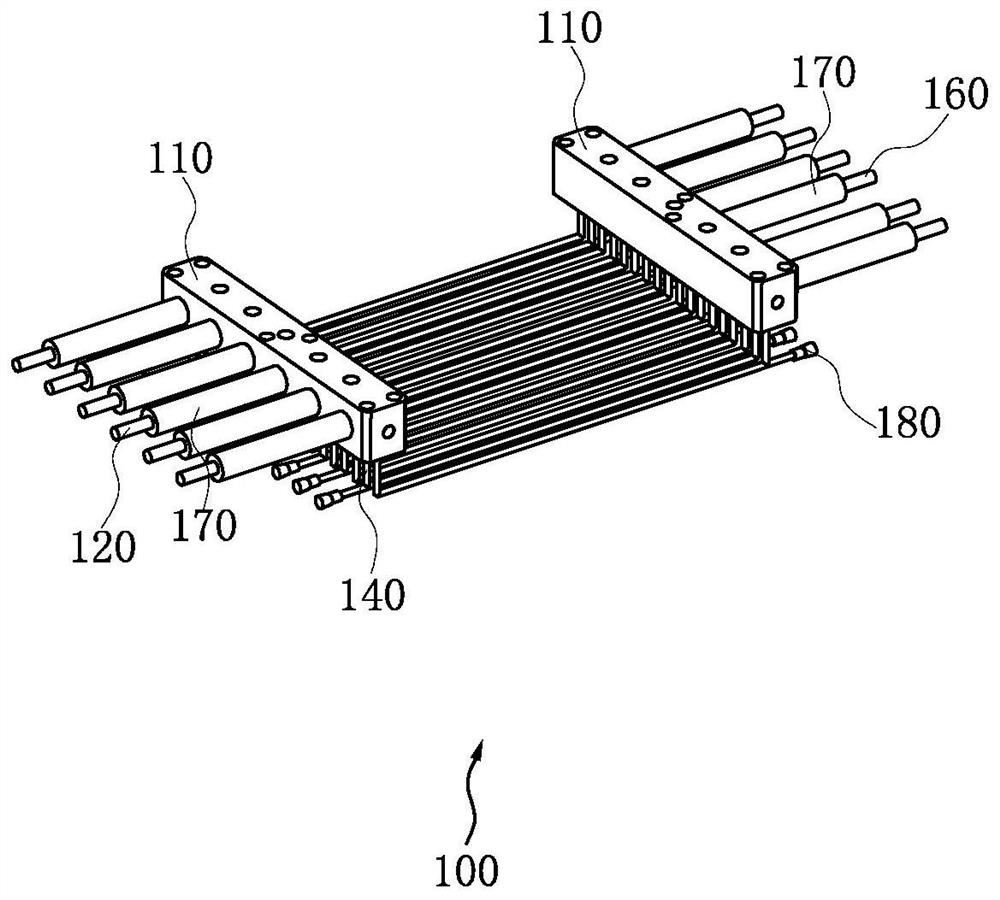

[0023] see figure 1 , figure 2 , image 3 and Figure 4 as shown, figure 1 It is a structural schematic diagram of the waterway structure of the mold core of the present invention, figure 2 It is an exploded view of the waterway structure of the mold core of the present invention, image 3 It is a partial schematic diagram of the waterway structure of the mold core of the present invention, Figure 4 It is a cross-sectional view of the waterway conversion structure of the waterway structure of the mold core of the present invention, and the waterway structure 100 of the mold core 10 includes:

[0024] Two waterway conversion structures 110, the two waterway conversion structures 110 are respectively arranged on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com