Construction method of anti-floating locating system of cast-in-place concrete hollow floorslab steel tube

A technology of hollow floor slab and construction method, which is applied to the preparation of floor slabs, formwork/formwork/work frames, and building components on site, and can solve the problems of the decline in the quality of concrete floor slabs, the protection of prefabricated hollow pipes, and the turnover times of floor slabs Few other problems, to achieve the effect of good construction appearance quality, stable formwork anti-floating system, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

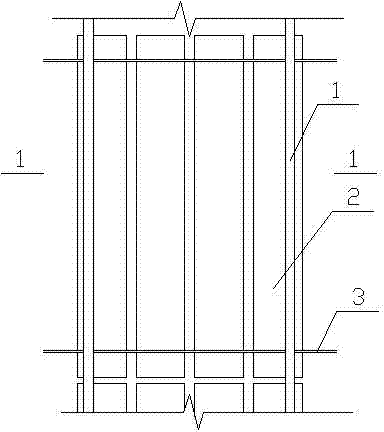

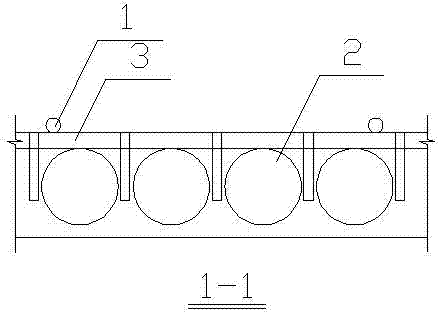

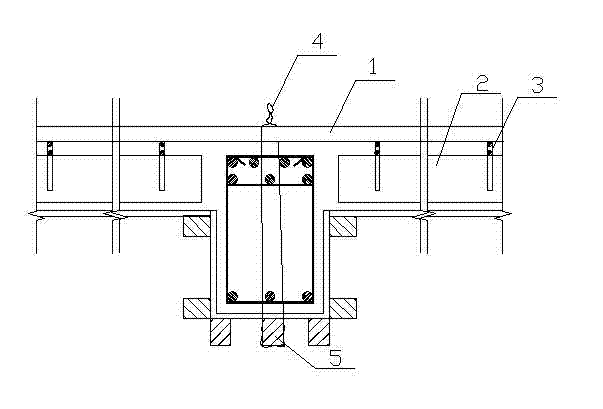

[0028] See attached Figure 1~4 , in the present embodiment, the construction method of the steel pipe anti-floating positioning system that limits the floating of the prefabricated hollow pipe in the hollow floor slab is carried out according to the following steps:

[0029] ①Establish the formwork support system according to the formwork support system selected in the construction plan;

[0030] ② After the formwork support frame is erected, support the beam bottom formwork, bind the beam reinforcement, install the beam side formwork, and finally install the roof formwork;

[0031] ③ After the floor formwork is installed and cleaned, mark the prefabricated hollow pipe 3 and the position line of the intercostal hidden beam, the position line of the bottom row of steel bars on the floor, the reserved hole for water and electricity, and the position li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com