Toughened film cutting device

A tempered film and cutting technology, applied in metal processing and other directions, can solve the problems of increasing shock absorption, affecting the vision of workers, and inconvenient cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] One of the core ideas of the present invention is to drive the cutter to cut vertically and horizontally through the coordinated movement of the gantry frame and the knife rest, so as to achieve the above-mentioned technical effects with a simple and direct mechanical structure.

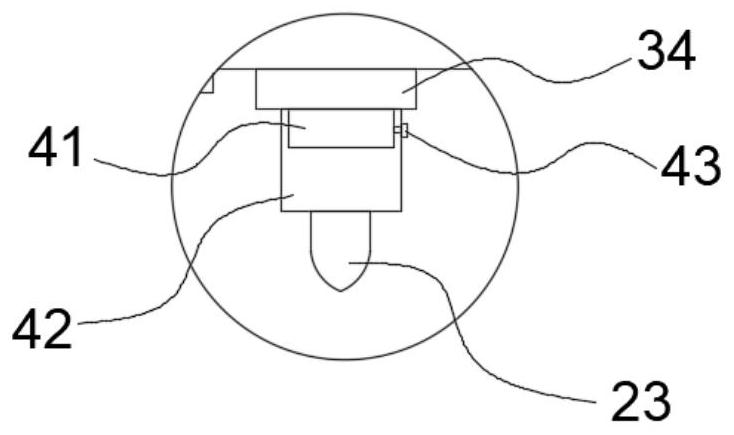

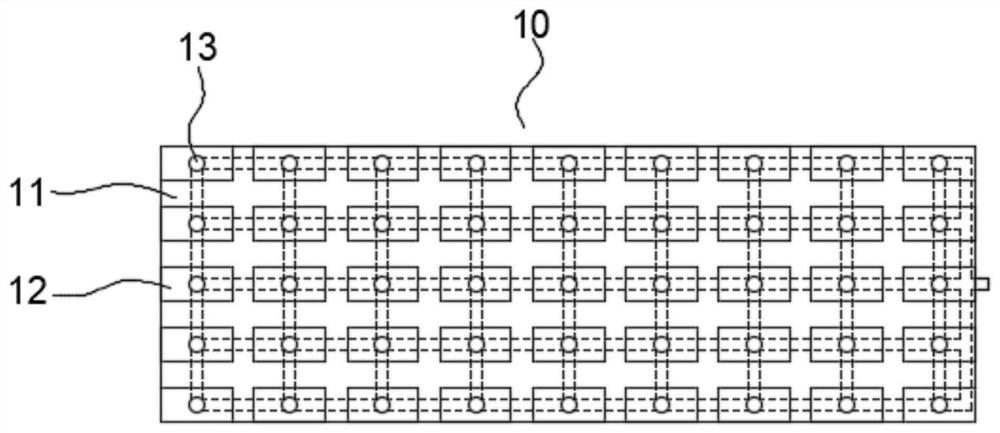

[0024] refer to Figure 1 to Figure 3 , which shows a schematic structural view of a tempered film cutting device of the present invention, which may specifically include:

[0025] The workbench 10 is set on the partition 16 inside the storage box 63, and a plurality of knife grooves 11 are provided in a criss-cross manner on the workbench 10 to form a plurality of evenly arranged placing blocks 12 for placing the entire tempered film sheet 64, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com