Activated carbon modification method for removing ammonia gas in air

A technology of activated carbon and ammonia, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as low ammonia adsorption capacity, no adsorption capacity, and affecting ammonia removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: as figure 1 Shown, a kind of activated carbon modification method for removing ammonia in the air, the specific steps include:

[0041] Step S1: Activated carbon pretreatment; use hydrochloric acid to clean the activated carbon, and open the pores of the activated carbon;

[0042] Step S2: Activated carbon modification treatment; use nitric acid and oxalic acid or phosphoric acid or succinic acid aqueous solution as the modification solution to impregnate the activated carbon, and use a shaker for oscillation treatment;

[0043] Step S3: activated carbon drying treatment; filtering the modified liquid and drying the activated carbon.

[0044] Specifically, the concentration of the hydrochloric acid solution is 5%, and the activated carbon is cleaned with an excessive amount of hydrochloric acid solution, which is conducive to forming more pore structures on the surface of the activated carbon and increasing the specific surface area.

[0045] Specificall...

Embodiment 2

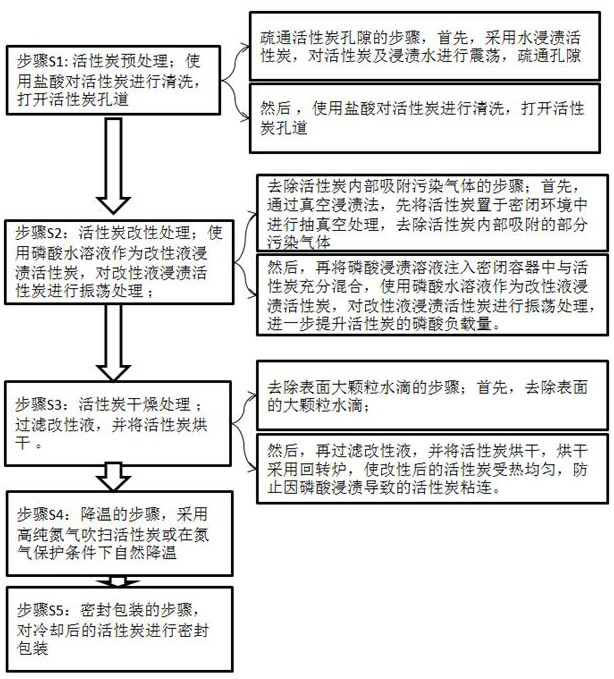

[0052] Embodiment 2: as figure 2 Shown, a kind of activated carbon modification method for removing ammonia in the air, the specific steps include:

[0053] Step S1: Activated carbon pretreatment; use hydrochloric acid to clean the activated carbon, and open the pores of the activated carbon;

[0054] Step S2: Activated carbon modification treatment; use oxalic acid, phosphoric acid or succinic acid aqueous solution as the modification solution to impregnate the activated carbon, and perform vibration treatment on the modification solution to impregnate the activated carbon;

[0055] Step S3: activated carbon drying treatment; filtering the modified liquid and drying the activated carbon.

[0056] Further, step S1 also includes the step of dredging the pores of the activated carbon. First, the activated carbon is impregnated with water, and the activated carbon and impregnated water are shaken to dredge the pores; then, the activated carbon is cleaned with hydrochloric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com