Triangular steel structure artificial reef

A technology for artificial reefs and steel structures, applied in fish farming, animal husbandry, applications, etc., can solve the problems of high self-weight and easy silting, prone to subsidence and silting, and high requirements for sediment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

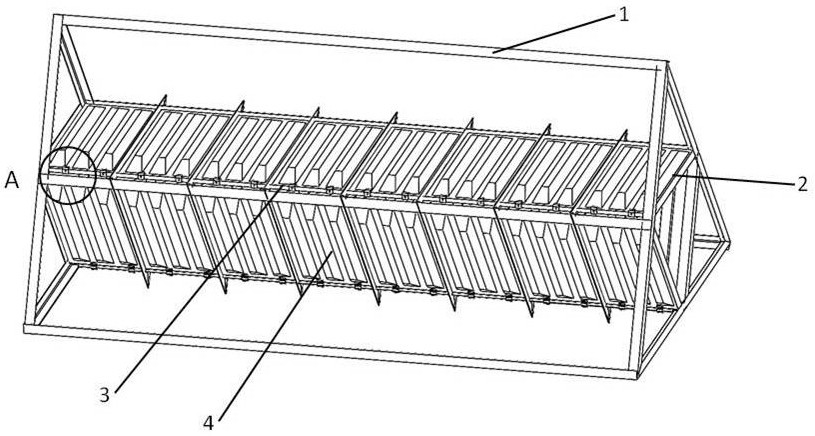

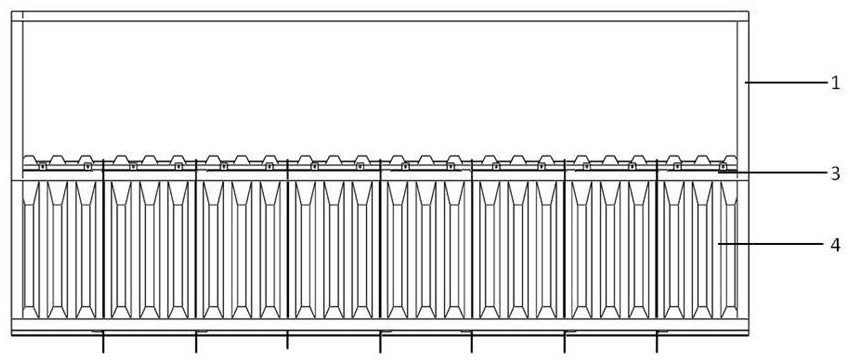

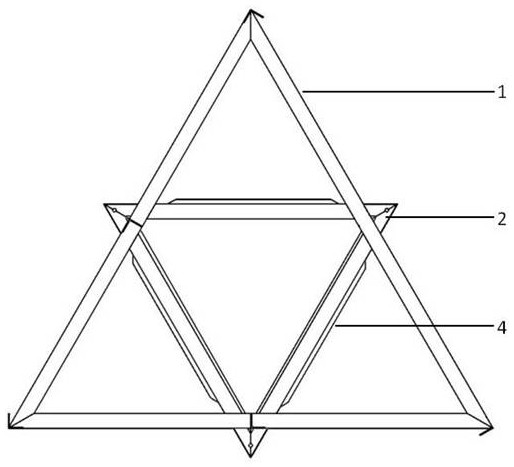

[0036] Such as Figure 1 to Figure 4 As shown, the triangular steel structure artificial fish reef includes the steel structure reef support frame and the attachment plate, and the detachable assembly connection between the steel structure reef support frame and the attachment plate, wherein:

[0037] The steel structure reef support frame includes an outer triangular reef support 1, an inner triangular reef support 2 and a fixed support 3, and the outer triangular reef support 1, the inner triangular reef support 2 and the fixed support 3 are made of 10CrMoAl angle steel ; 10CrMoAl steel is a special steel resistant to seawater corrosion. Al (aluminum) in 10CrMoAl material can chemically react with O (oxygen) in the air to form Al2O3 (aluminum trioxide), thus forming a protective film, which is both anti-corrosion and corrosion-resistant; Cr (chromium), Mo ( Molybdenum) ions in seawater can automatically replenish the gaps formed by Cl (chloride) ions on steel pitting corros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com