Dedicated hybrid transmission, particularly as part of a drive train, and operating method of such a drive train

A transmission device and transmission ratio technology, which is applied in the field of special hybrid transmission device and drive unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

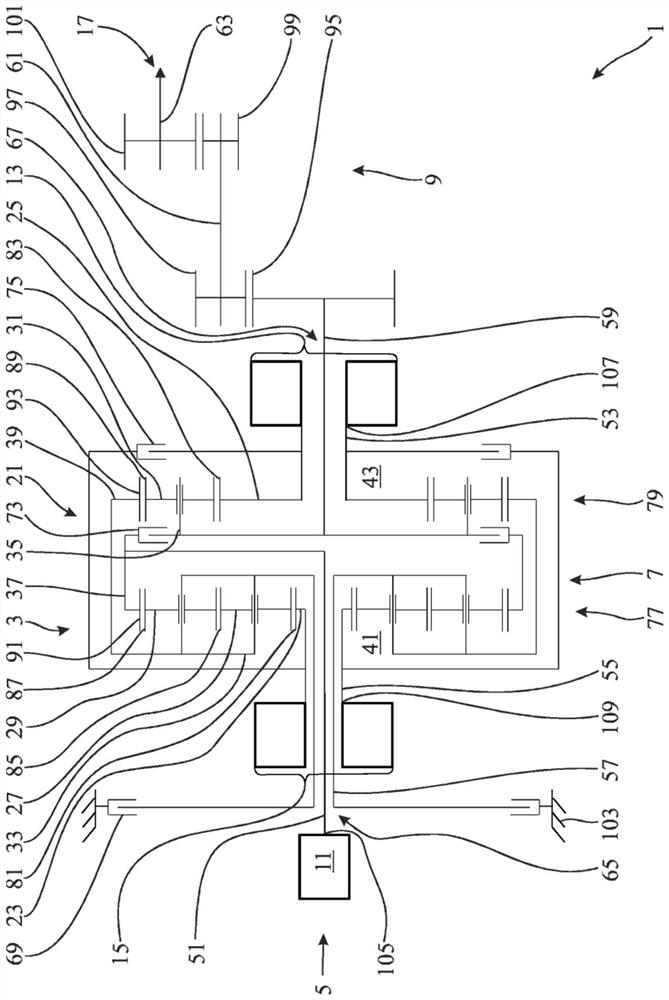

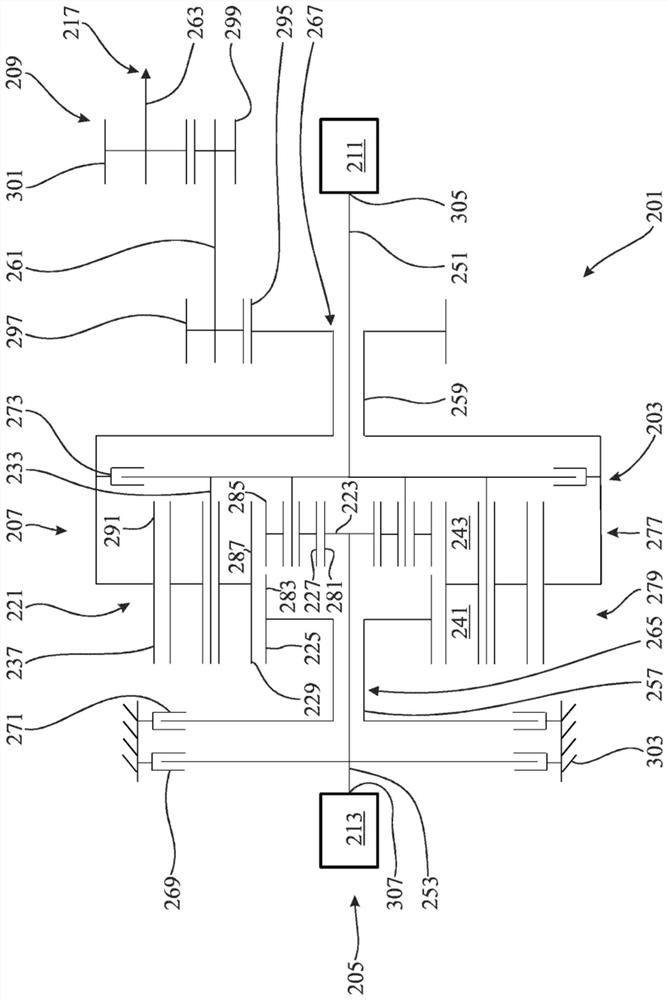

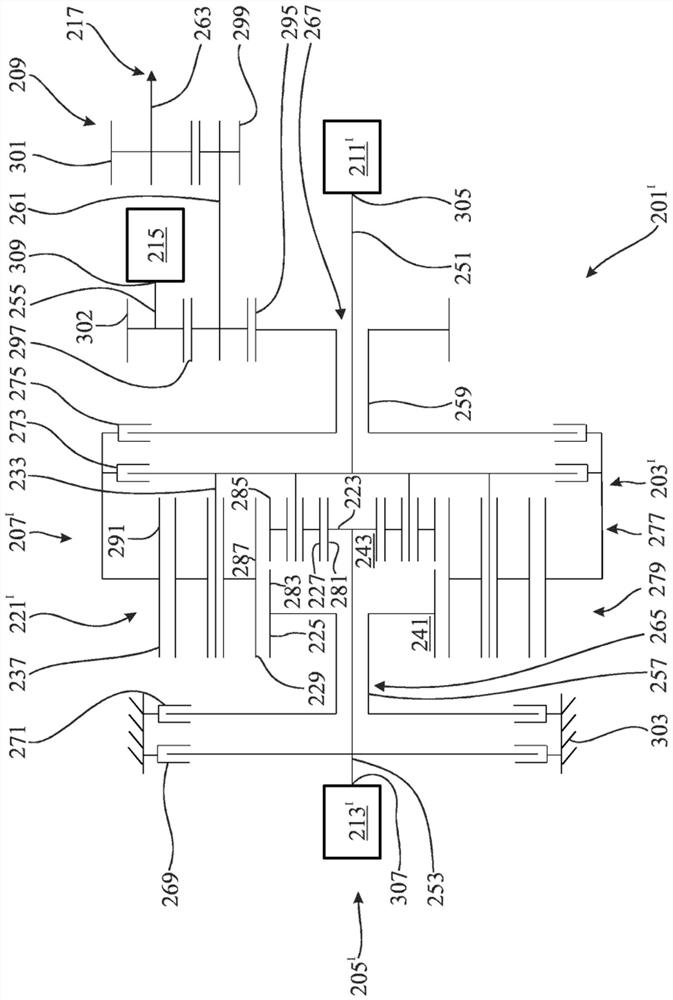

[0142] The different exemplary embodiments are based on identical, identical or at least similar subjects, components, parts, components and parts, so that the individual parts, components, parts, components and objects between the different embodiments are numbered with reference numbers increased by 200 respectively. The descriptions and explanations of the individual subjects, components, parts, components and parts can be transferred from one embodiment (if necessary in an adapted form) to another embodiment by transferring the respective Reference numbers are raised or lowered by the corresponding multiple of 200. In other words, many of the explanations of one of the first exemplary embodiments can also be transferred to the presently presented exemplary embodiment, so that for reasons of a more compact and clear description, only specific aspects are in each case described for the latter exemplary embodiments , but the general description can likewise be transferred (wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com