Actuating arm drive

A technology of driving device and adjusting arm, which is applied to the suspension device of the wing leaf, door/window fittings, wing leaf parts, etc., which can solve the problems of increased space requirements, obstruction of extension, furniture damage, etc., to save space and simplify orientation and the effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

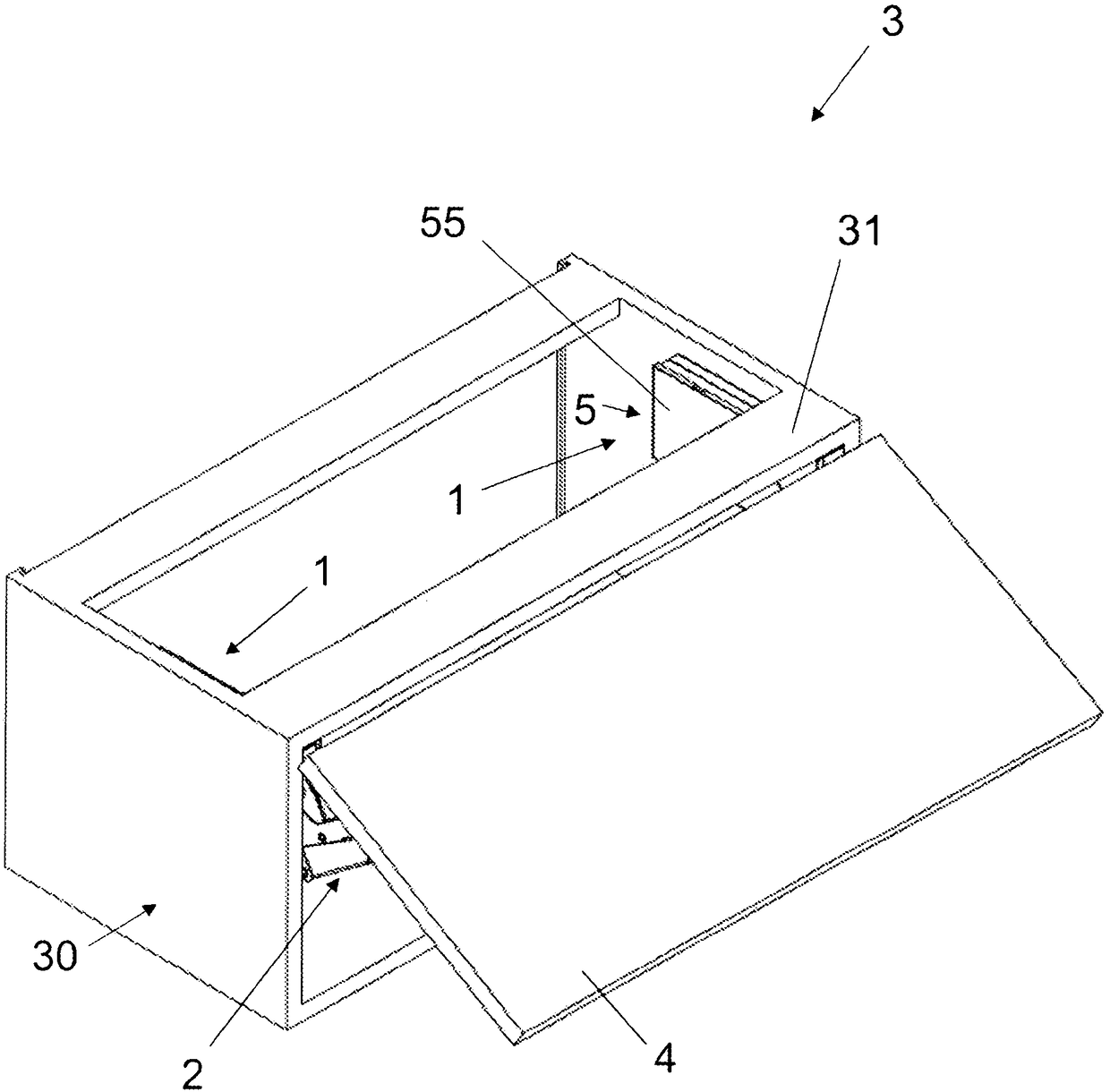

[0038] Figure 1a A piece of furniture 3 is shown with a furniture body 30 , in the interior of which two adjusting arm drives 1 are fitted below a furniture body cover 31 . A movable flap 4 is fastened to the adjusting arm 2 of the adjusting arm drive 1 and is thus mounted pivotably on the furniture body 30 by means of the adjusting arm drive 1 . The adjusting arm drive device 1 is fastened to the furniture body 30 via the housing 5 provided with the housing cover 55 .

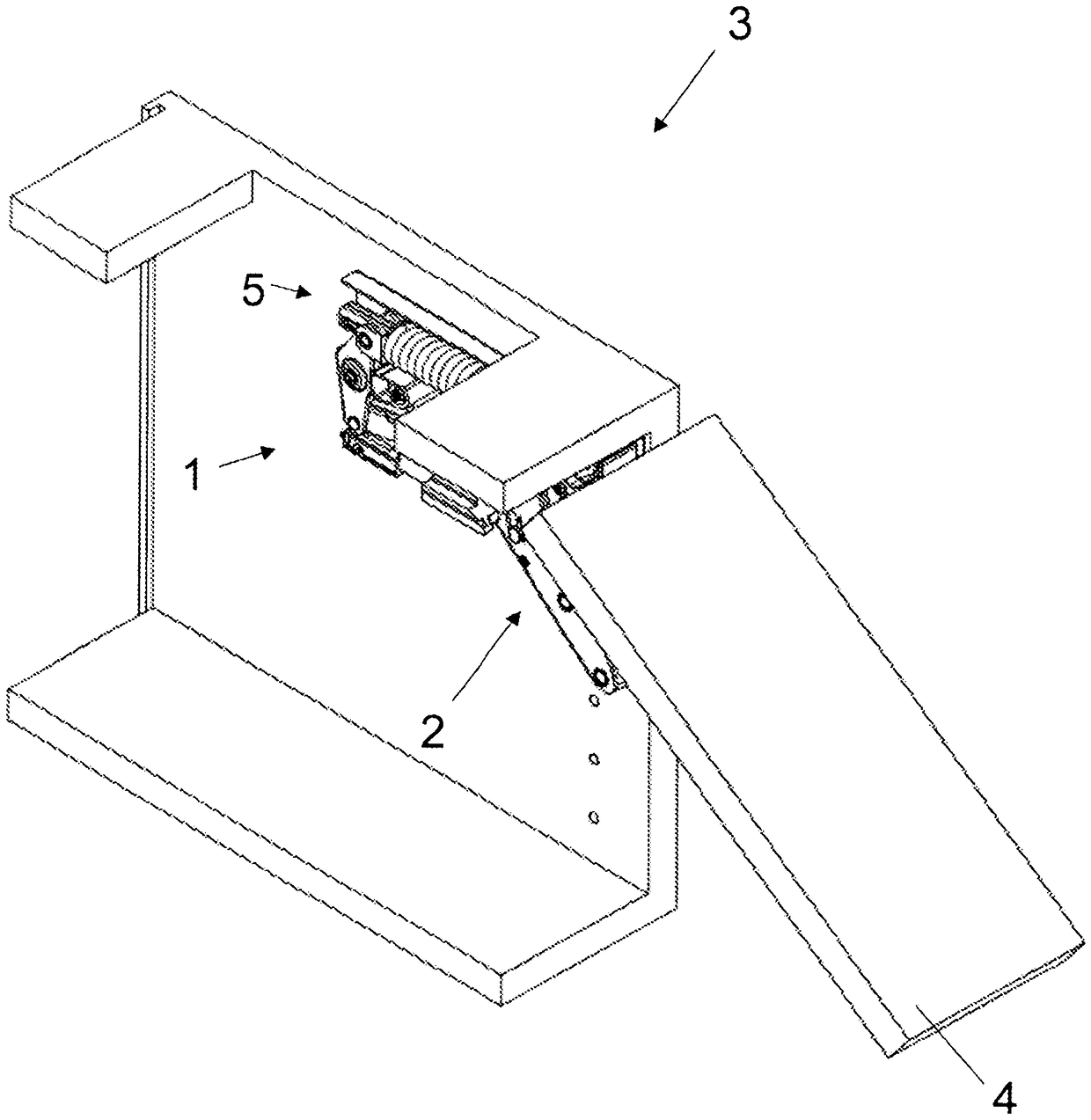

[0039] Figure 1b A perspective view of a cutaway section of the piece of furniture 3 shown in FIG. 1 is shown, wherein the adjusting arm drive 1 is shown without the housing cover 55 of the housing 1 . As mentioned above, the shutter 4 is fastened to the adjusting arm 2 of the adjusting arm drive 1 .

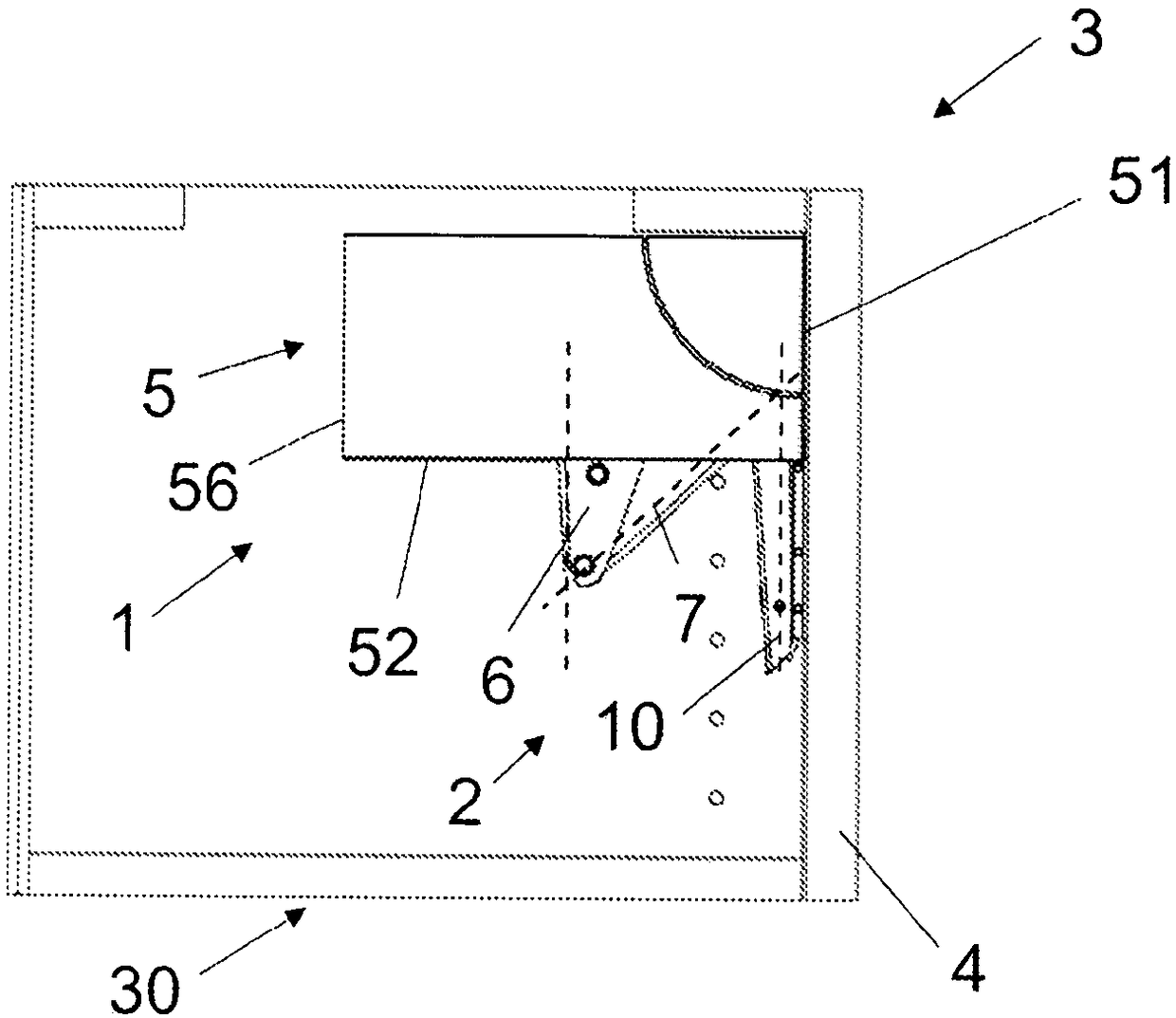

[0040] Figures 2a to 2d The sequence of the opening movement (or in reverse order the sequence of the closing movement) of the piece of furniture 3 with the pivotably mounted flap 4 is shown. here in Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com