Cargo allocation optimization method based on logistics total quantity and energy consumption

A technology of energy consumption and optimization method, which is applied in the field of logistics and warehousing, and can solve the problems of not considering the optimization management of cargo space as a whole, low efficiency, and insufficient utilization of warehouse space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

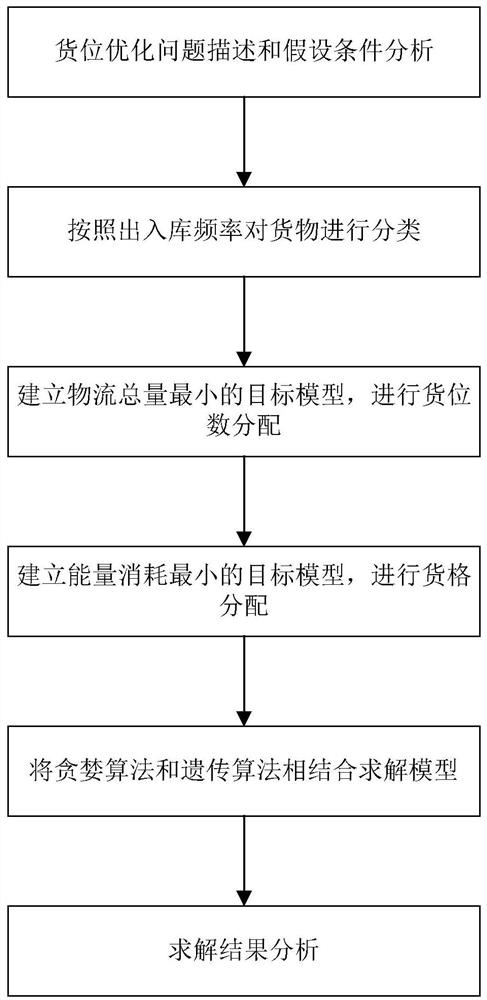

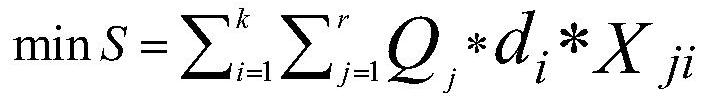

Method used

Image

Examples

Embodiment 1

[0060] 1. Description of cargo location optimization problem and analysis of assumptions

[0061] The warehouse in this embodiment has a total of 4 rows of shelves, and each row of shelves has 4 layers and 12 rows, that is, each row has a total of 48 compartments. The specifications of the shelves are: each storey is 1m high, 1.4m wide, and each compartment is 2m long. A total of 8 different types of chipsets are stored in the warehouse. The optimization of cargo space is to reasonably allocate the cargo space in the warehouse according to the characteristics of the goods and the storage environment, and arrange storage points for different goods. Therefore, in order to improve the efficiency of goods in and out of the warehouse and improve the resource utilization rate of the warehouse, a multi-objective optimization model is established with the total logistics and energy consumption as the objective function. The following assumptions are satisfied during the entire cargo lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com