Anchor rod cable system cooperative bearing performance testing device and method

A test device and a technology of anchor cables, which are applied in the field of collaborative load-bearing performance test devices, can solve problems such as the design of anchor cable parameters in large-deformation tunnels, and achieve the effects of effectively guiding on-site construction, convenient operation, and weakening friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

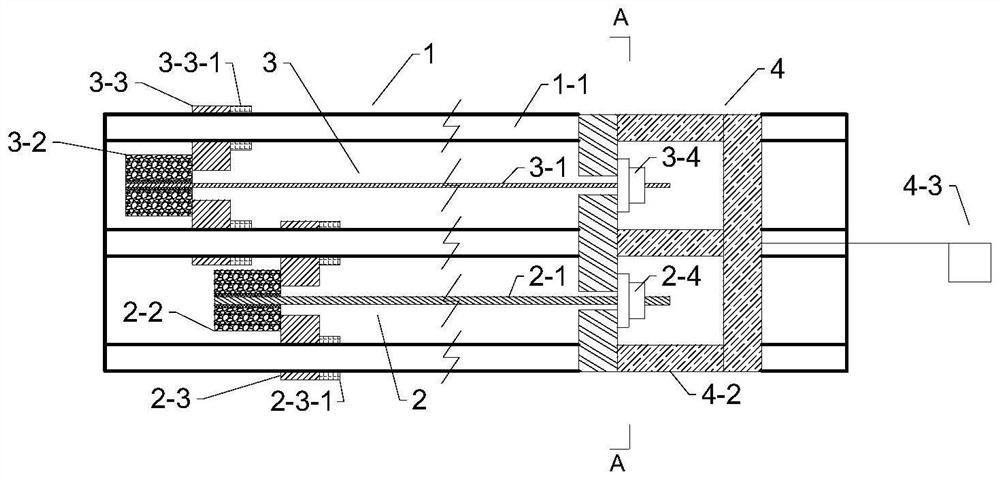

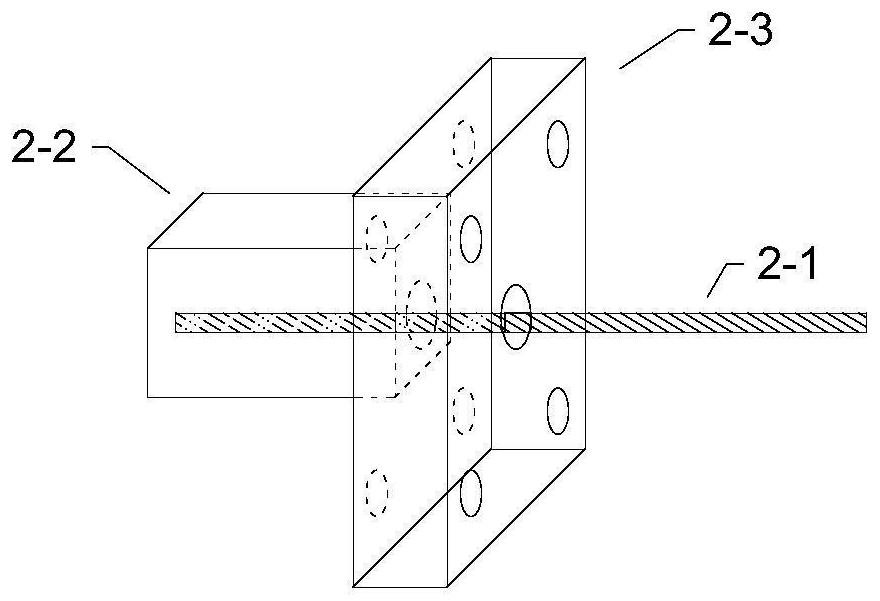

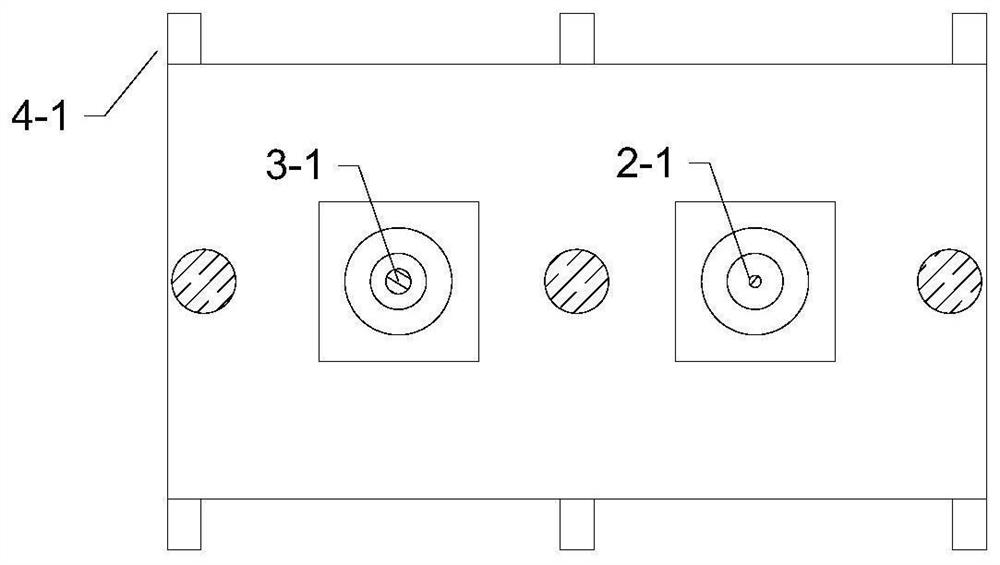

[0043] Embodiment 1, the horizontal spacing of the guide rail 1-1 is 0.5m, the vertical spacing of the guide rail 1-1 is 0.5m, the length of the guide rail 1-1 is 10m, and the rigidity of the guide rail 1-1 is the anchor rod 2-1 and the anchor cable 10 times the rigidity of anchor rod 3-1; the rigidity of anchor rod limiter 2-3 is 10 times that of anchor rod 2-1; the rigidity of anchor cable limiter 3-3 is that of said anchor cable 3-1 10 times the stiffness; the stiffness of the traction frame 4-2 needs to meet the two conditions of 10 times the stiffness of the anchor rod 2-1 and more than 10 times the stiffness of the anchor cable 3-1.

[0044] In specific implementation,

[0045] 1) A tunnel support is designed with a bolt length of 2.6m, a diameter of 25mm, and an anchorage length of 1.8m, using a 150×150×8mm butterfly tray with a pre-tightening force of 80kN; an anchor cable length of 6.3m, a diameter of 17.8mm, and an anchorage length of 1.7 m, preload 100kN. Comparin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com