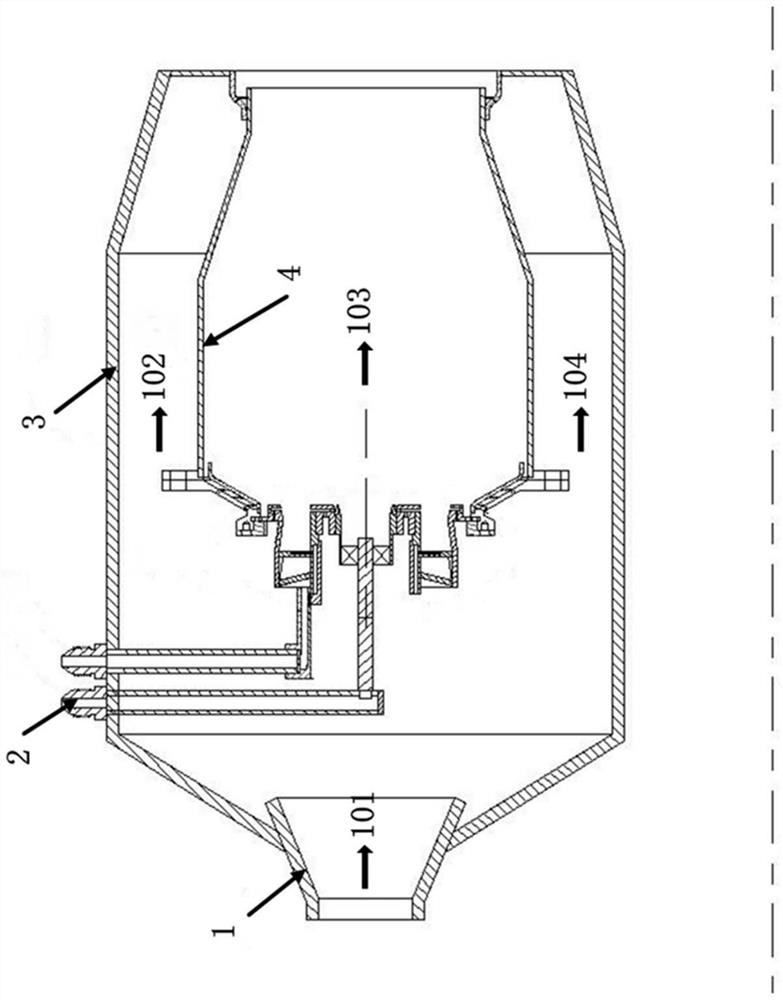

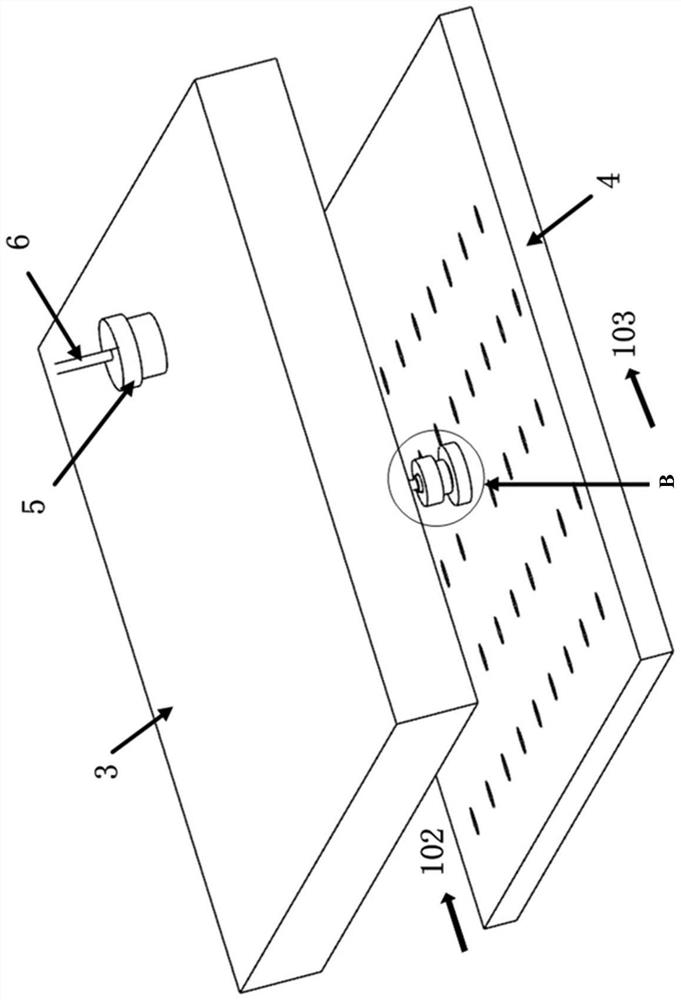

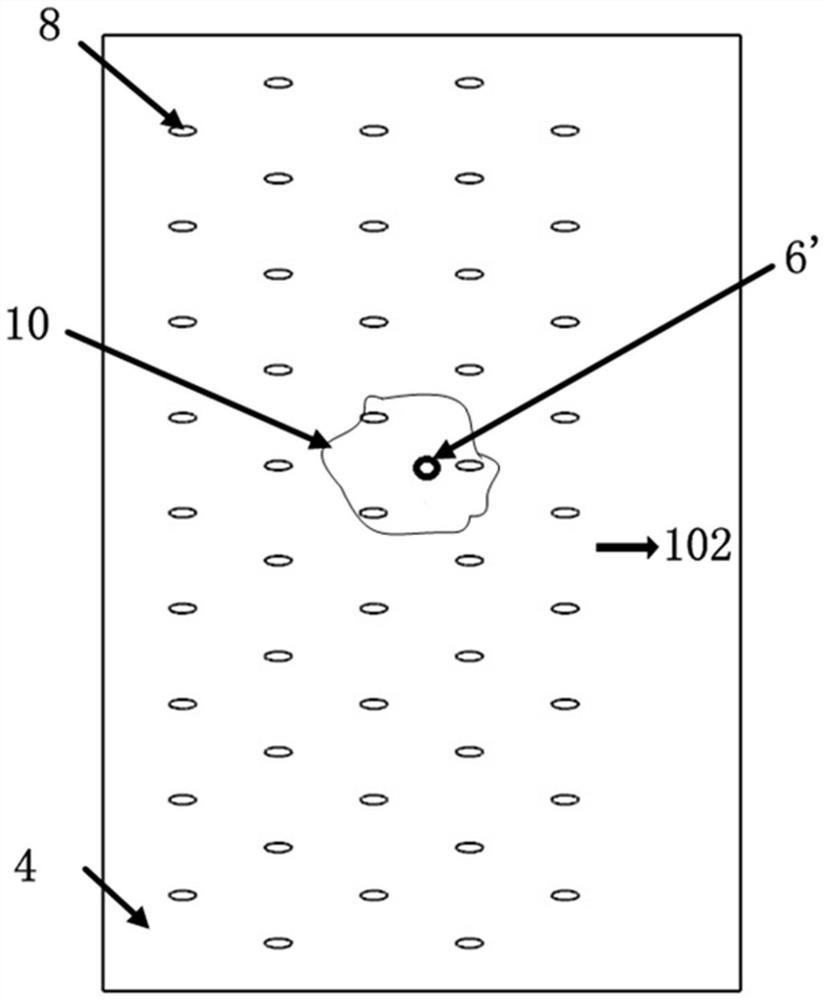

Static pressure measuring structure for wall surface of flame tube, connecting device, combustion chamber and combustion chamber test system

A technology of connecting device and flame tube, which is applied in the field of measuring structure of static pressure on the wall of flame tube, can solve the problems such as difficult to replace, need to wait on site, increase the risk of assembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following discloses a variety of different implementations or examples for implementing the described subject technical solutions. In order to simplify the disclosure, specific examples of various elements and arrangements are described below, which are, of course, only examples and are not intended to limit the scope of protection of the present invention.

[0035] In addition, it should be understood that the orientation or positional relationship indicated by orientation words such as "front, rear, top, bottom, left, right", "horizontal, vertical, vertical, horizontal" and "top, bottom" and the like are usually Based on the orientation or positional relationship shown in the drawings, it is only for the convenience of describing the present invention and simplifying the description, and these orientation words do not indicate or imply that the indicated device or element must have a specific orientation unless otherwise stated. Or be constructed and operated in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com