Automatic measurement method for working edge straightness of knife-edge ruler

An automatic measurement and straightness technology, applied in the direction of measuring devices, manufacturing tools, workpiece clamping devices, etc., can solve the problems of easily affected verification results, low verification efficiency, low detection efficiency, etc., to improve detection accuracy and detection The effect of improving efficiency, avoiding test errors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

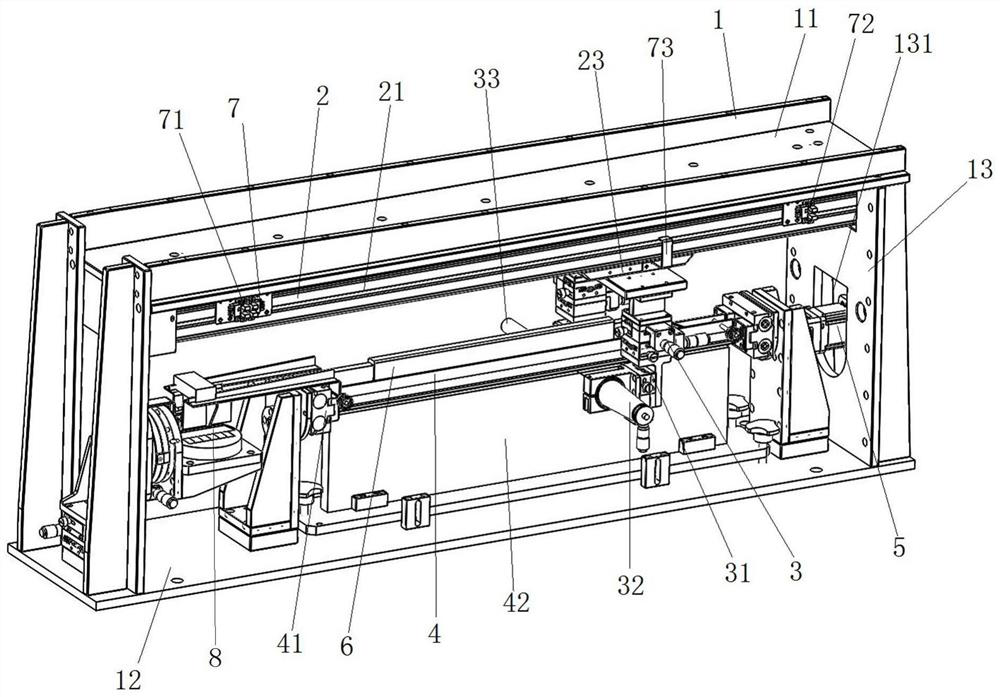

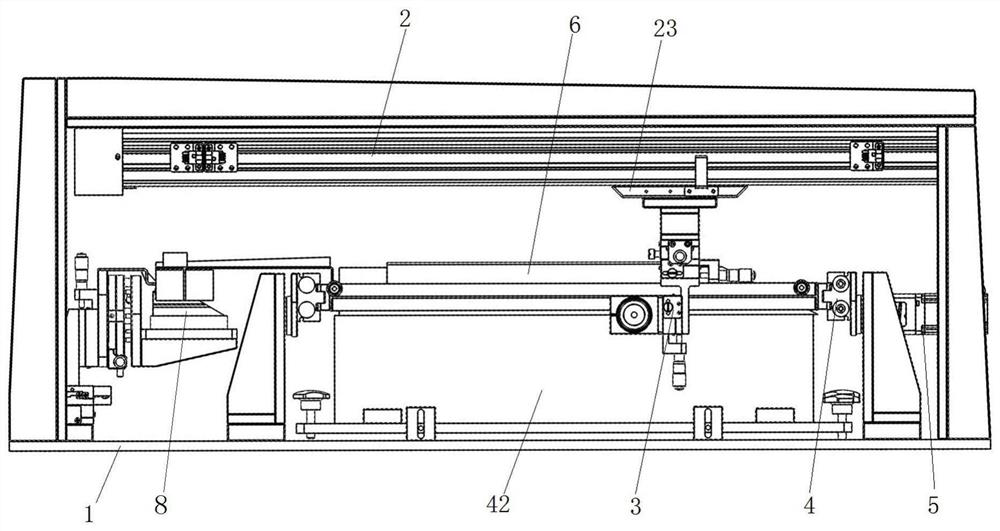

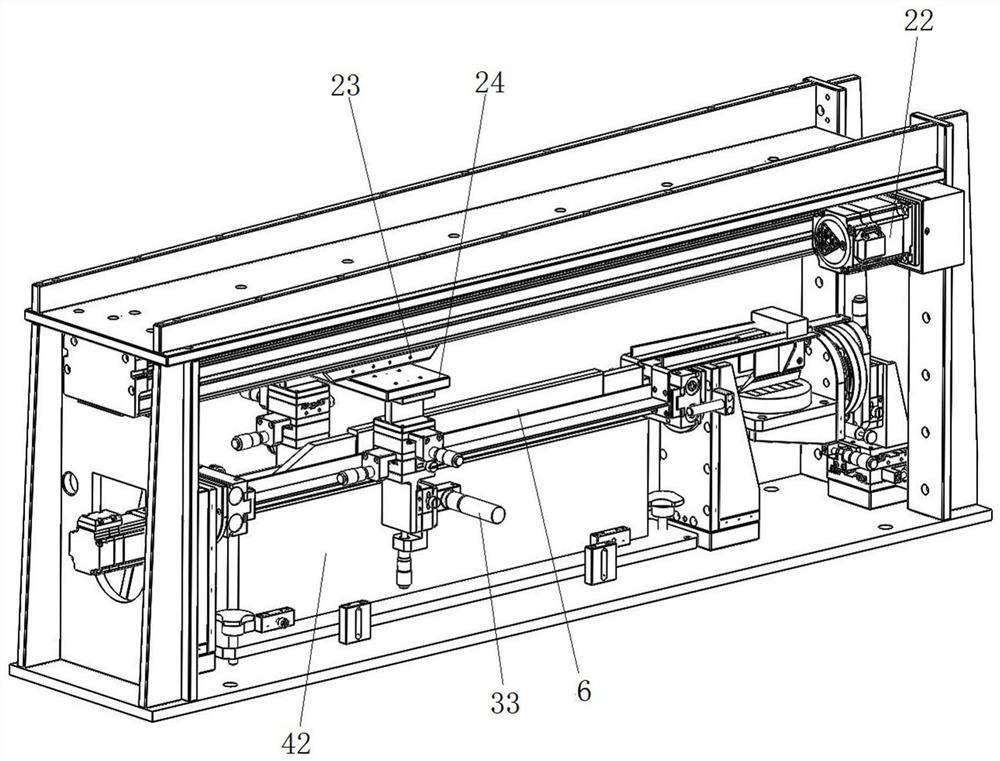

[0086] A method for automatically measuring the straightness of the working edge of a knife-edge ruler, which is based on an automatic measuring device for the straightness of the working edge of a knife-edge ruler. Knife-edge ruler working edge straightness automatic measuring device, combined with Figure 1 to Figure 24 As shown, a housing 9 is included, and the housing 9 is provided with a frame 1, a grinding surface ruler 42, a clamping centering device 4, a rotating drive device 5, a light measuring device 3, a light transmission gap data comparison device 8, a switching power supply and Control System.

[0087] The interior of the shell is sprayed black as a whole, and the darkroom eliminates the interference of other light waves, eliminates the backlight of data acquisition, and facilitates the taking and adjustment of each ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com