Automatic rice steamer filling machine with rotatory center

A rotary device, automatic technology, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of large human factors, high falling height of materials, and many mechanical movements, so as to overcome the influence of human factors, improve work efficiency, and improve the falling height. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

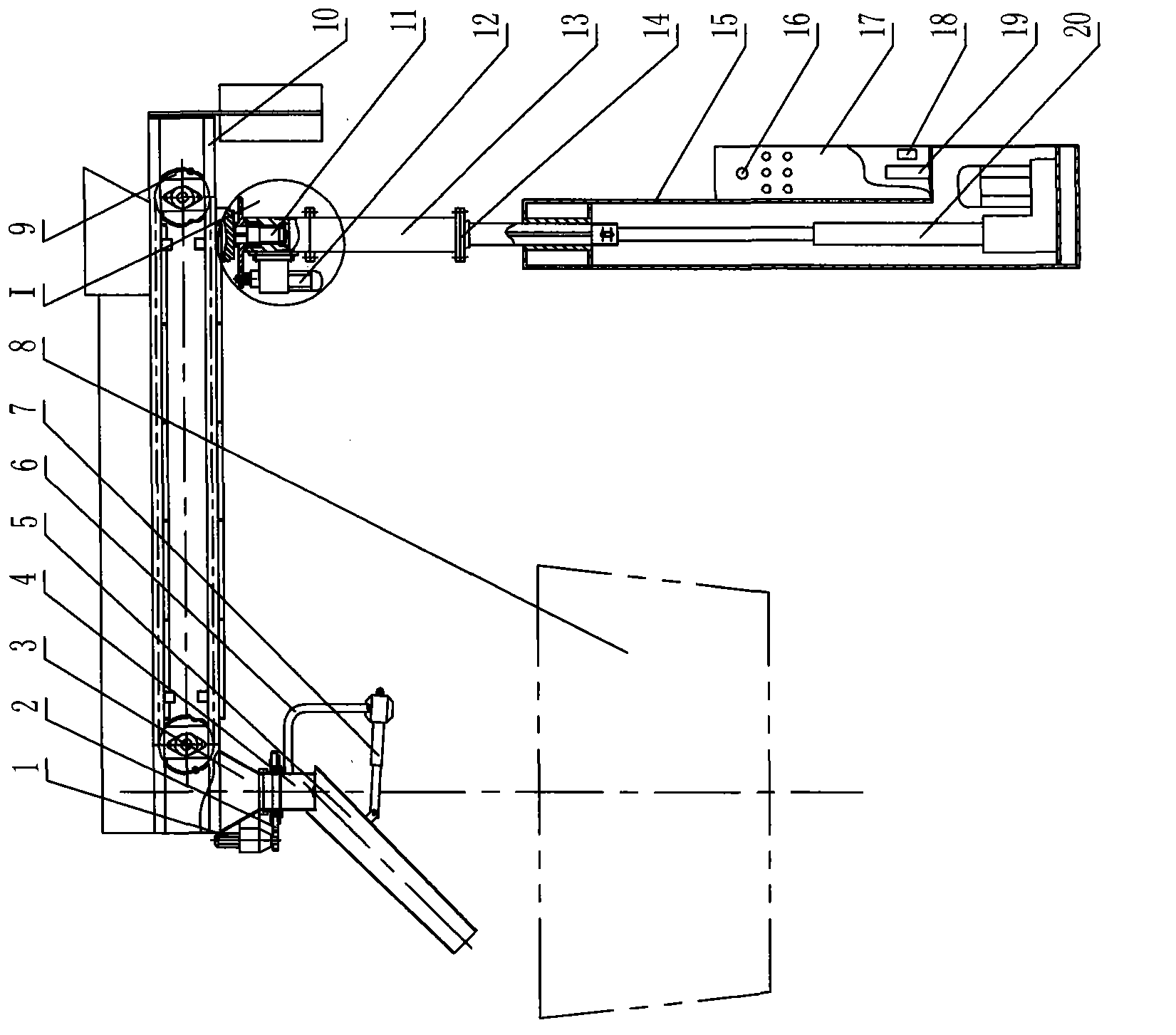

[0009] As shown in the figure, the present invention includes a lifting and turning device 14, a support 10, a conveyor 9 and a distribution device 6, the conveyor 9 is arranged on the support 10, and the distribution device 6 and the lifting and turning device 14 are respectively connected to the output end of the conveyor 9, The support 10 below the input end is connected, and the lifting and turning device 14 is also provided with PLC18 and frequency converter 19. The frame lifting and turning device 14, the conveyor 9, and the distributing device 6 are controlled.

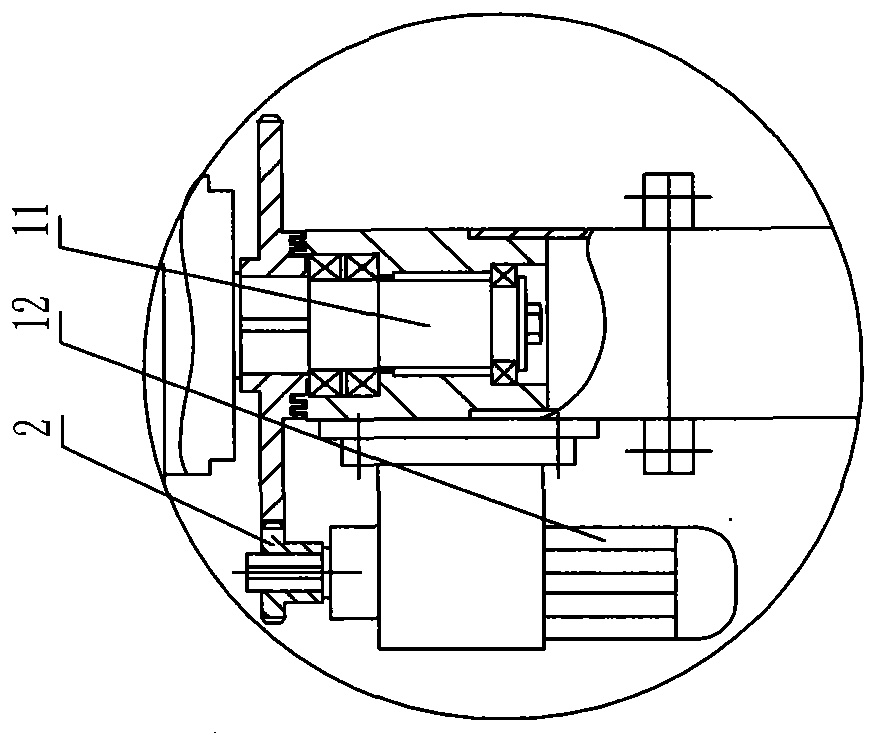

[0010] The lifting and turning device includes a support 15, a lifting electric push rod 20 arranged in the support 15, a slewing frame 13 connected to the upper end of the lifting electric push rod 20, a rotating shaft 11, and a rotating motor 12. The rotating shaft 11 and the rotating motor 12 pass through the gear 2 Connected, the lower end of the rotating shaft 11 is arranged in the slewing frame 13, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com