Glove demolding counting machine and demolding counting method thereof

A counting machine and glove technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve the problems of uneven arrangement of gloves, harsh production environment, and reduced production efficiency, so as to facilitate the arrangement of gloves, save height and space, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below through specific examples.

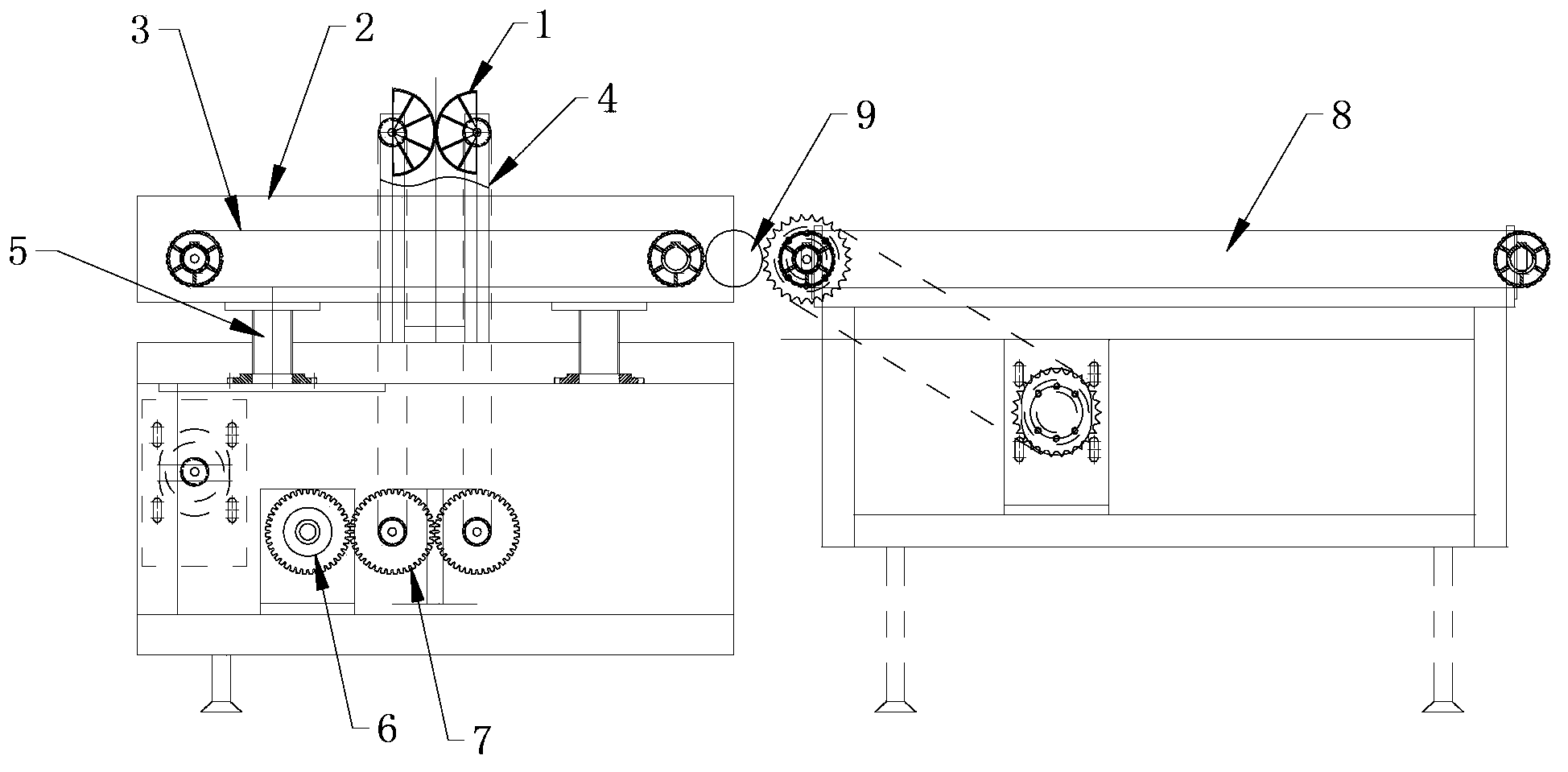

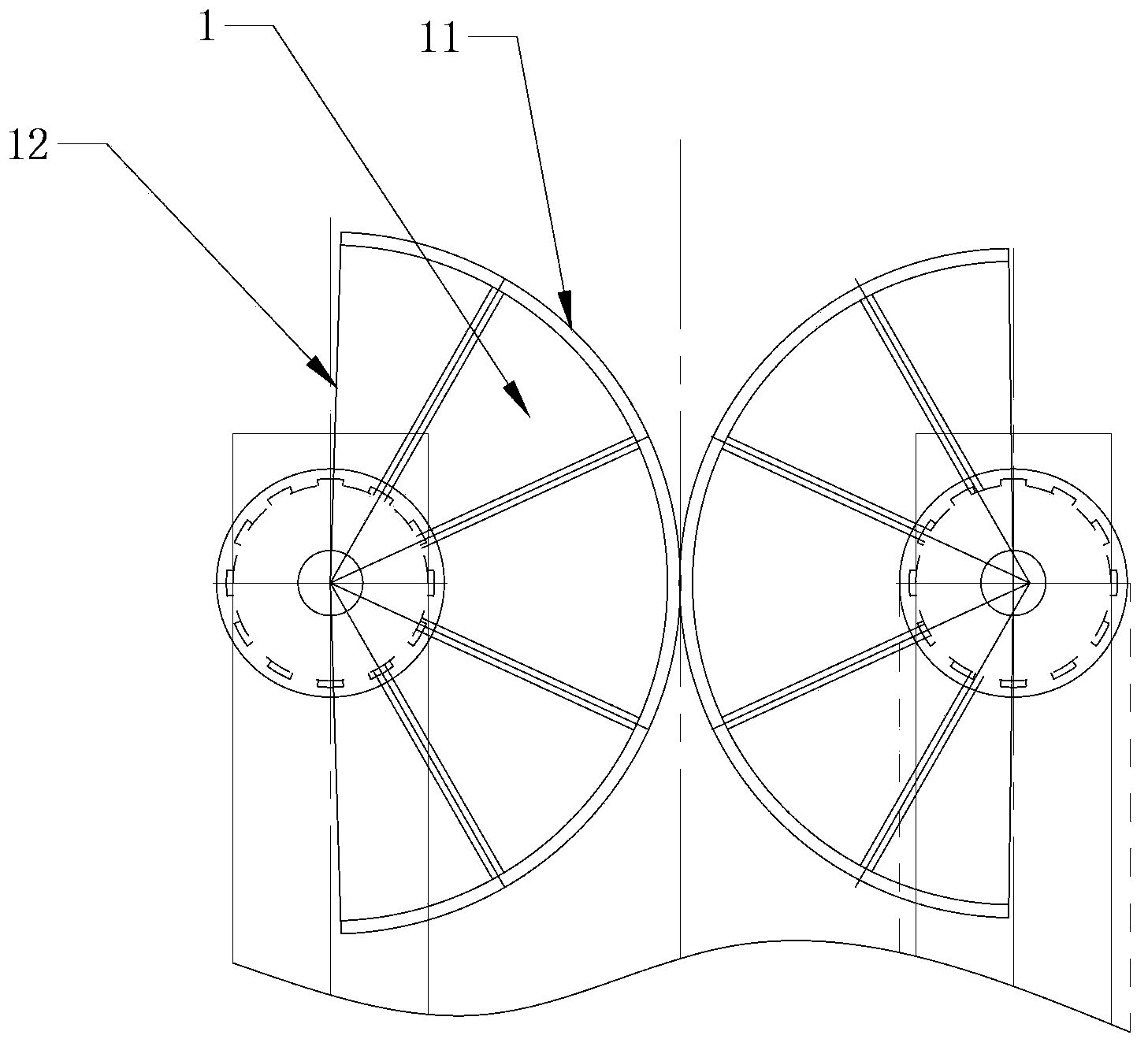

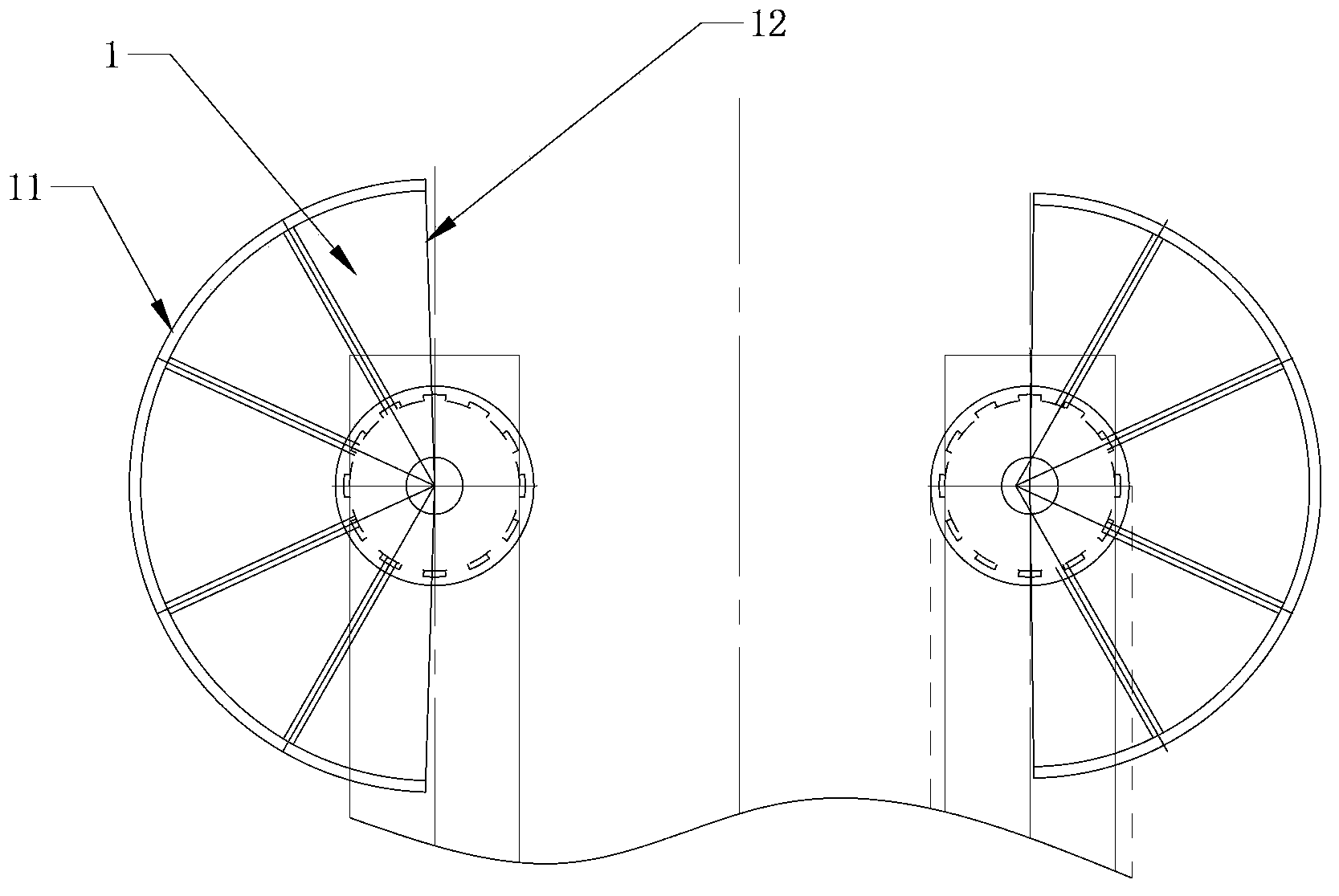

[0035] Such as figure 1 As shown, a glove demoulding counting machine includes a frame, a glove demoulding device and a belt conveyor 3, the glove demoulding device includes a support 4 and a pair of cooperating demoulding wheels 1, the support 4 is two poles, also can be a bearing, and each demoulding wheel 1 is rotatably installed on a bar, and this bearing 4 is fixed on the frame and is positioned at the side of frame. The gloves run successively from the sides of the rack along with the hand molds. The two stripping wheels 1 are driven to rotate synchronously by the stripping wheel driving device 6. The stripping wheel driving device 6 includes a driving motor, and a driving gear is installed on the output shaft of the motor, and the driving gear drives the stripping wheel through two synchronous gears 7. The mold wheel 1 rotates synchronously. Such as figure 2 , 3 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com