Combined multi-stage energy saver of equipment for recycling residual steam of waste water and waste heat

An energy-saving, combined technology, applied in heat exchange equipment, heat recovery systems, lighting and heating equipment, etc., can solve the problems of difficulty in using waste heat and waste steam at the same time, low recovery efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

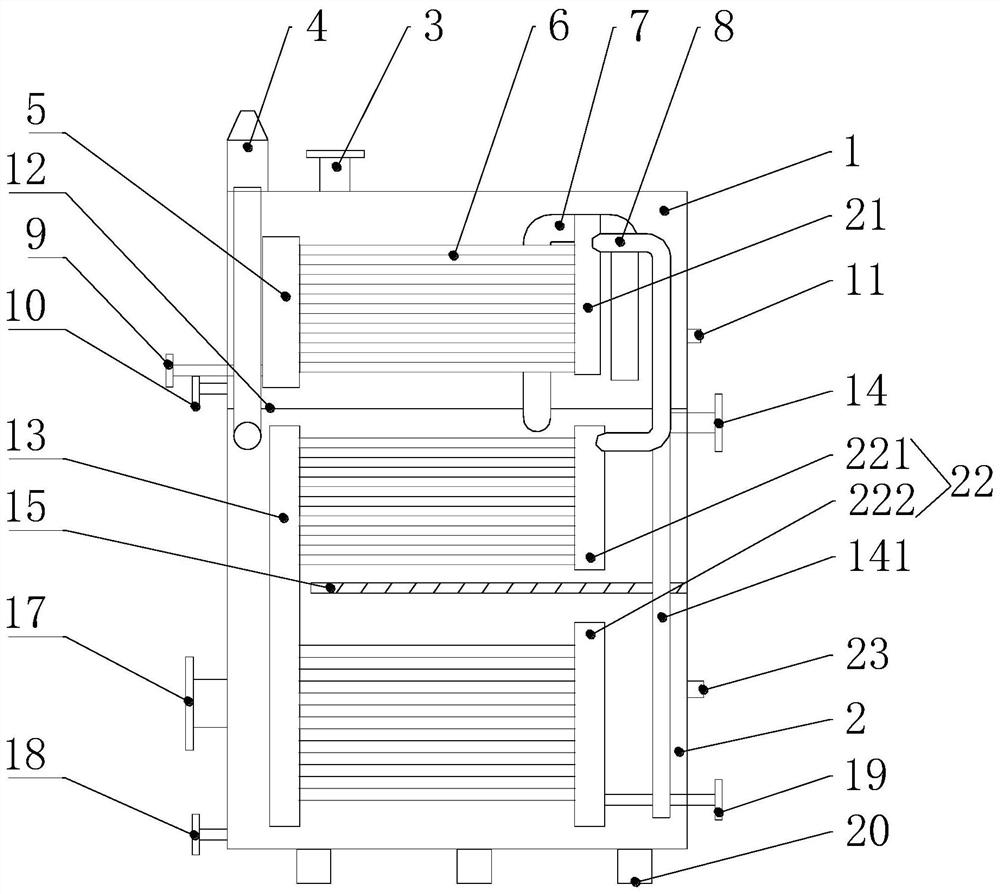

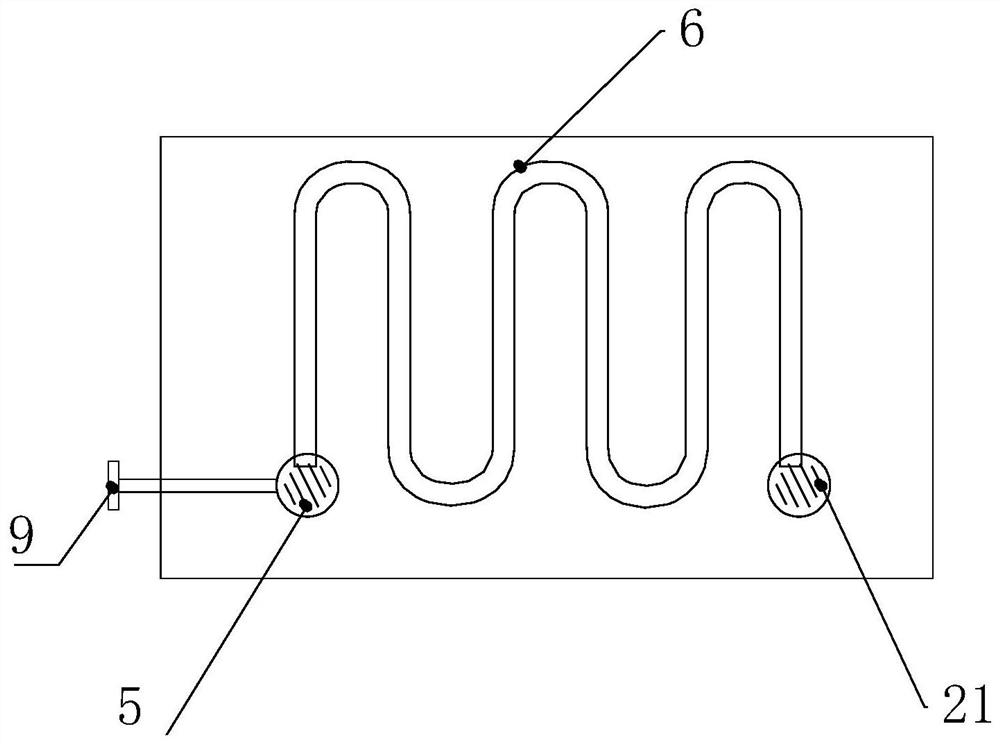

[0027] See figure 1 , the present invention has energy concentrator 1, economizer 2, and energy concentrator 1 and economizer 2 are box structures, and energy concentrator 1 is installed on the top of economizer 2, separates with clamping plate 12. The energy concentrator 1 is equipped with a first header 5, a second header 21, a serpentine pipe 6, a tank diversion pipe 7, and a waste heat diversion pipe 8, and an energy storage energy inlet device 3 and a condensate discharge pipe are arranged outside Seat 9, one end of the serpentine tube 6 is connected to the first header 5, the other end is connected to the second header 21, one end of the tank guide pipe 7 is connected to the interior of the economizer 2, and the other end is connected to the interior of the energy concentrator 1, and the condensed water The discharge pipe seat 9 communicates with the first header 5, and the storage energy inlet device 3 is installed on the top of the concentrator 1 and communicates with ...

Embodiment 2

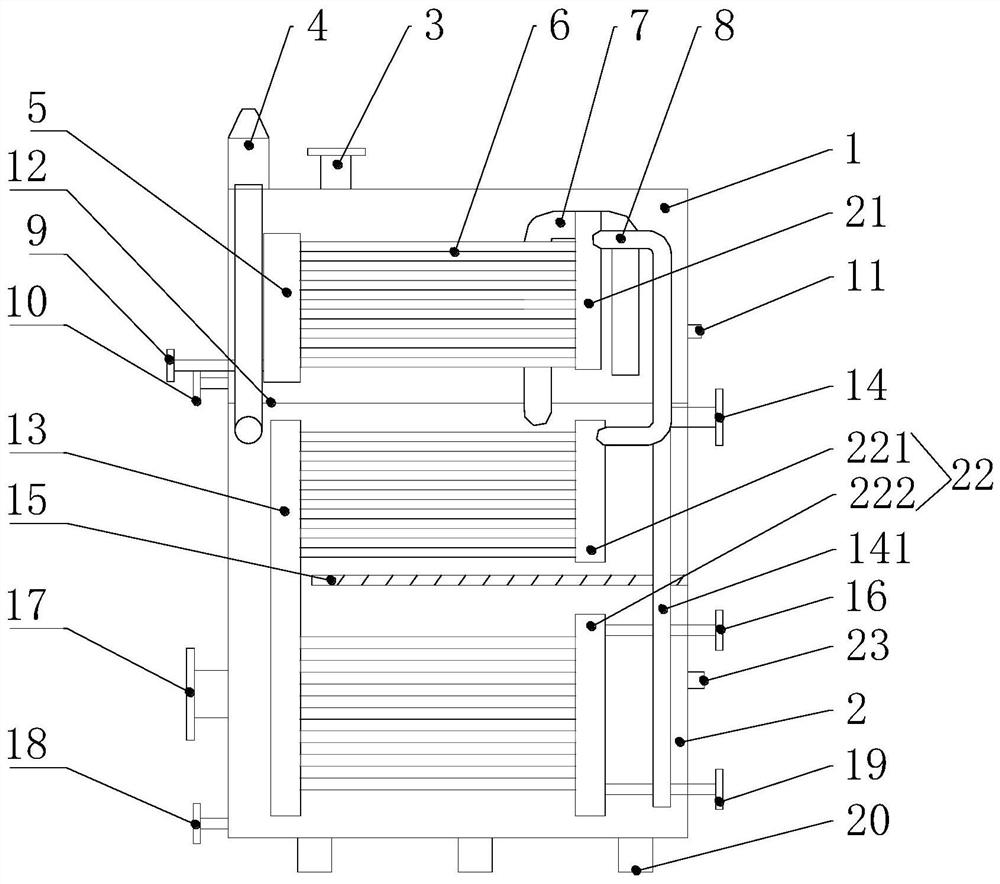

[0041] See figure 2 , this embodiment is basically the same as Embodiment 1, and its distinguishing feature is that: a waste heat source inlet socket 16 is also provided on the side wall of the economizer 2, and the waste heat source inlet socket 16 communicates with the right header 22. Two different heat sources can be recovered at the same time through the waste heat source inlet pipe socket 16 and the residual steam inlet pipe socket 19, which is fast and efficient.

[0042] working principle:

[0043] According to the actual waste heat conditions of different customers, one or more residual steam inlet sockets 19 are provided, or the waste heat source inlet sockets 16 and the residual steam inlet sockets 19 can be used together. The storage energy enters the box body of the concentrator 1 from the energy storage energy inlet device 3 , flows into the box body of the economizer 2 through the box guide pipe 7 , bypasses the clip guide plate 15 , and finally exits the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com