Final-stage reheater temperature adjusting device and operation method thereof

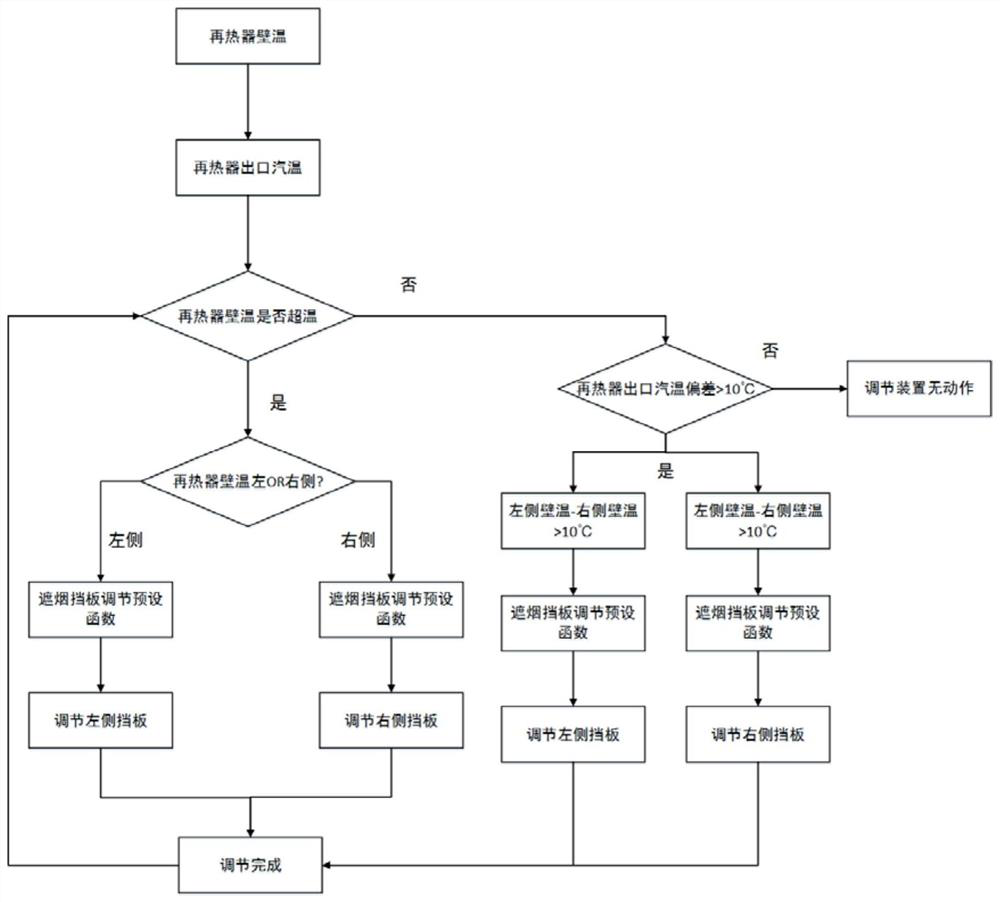

A final stage reheater and temperature adjustment technology, which is applied in the direction of steam generation method, combustion method, feed water heater, etc. using heat carrier, can solve the problem of low precision, difficulty in adjusting the temperature of the final reheated steam, and the adjustment of steam temperature Time lag and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 and figure 2 , figure 1 Middle A is the present invention, and the device for adjusting the temperature of the final stage reheater according to the present invention includes a controller, a rotating motor 82, a driving wheel 83, a driven wheel 84, a hydraulic cylinder 85, a hydraulic cylinder piston rod 86, and a smoke-shielding baffle 88 and a power supply box 81 for providing electric energy, wherein the smoke baffle 88 is located between the high-temperature superheater 5 and the final reheater 7 in the horizontal flue of the boiler, and the output shaft of the rotating motor 82 is connected with the driving wheel 83, The driving wheel 83 is matched with the driven wheel 84, the driven wheel 84 is connected with the upper end of the smoke baffle 88, one end of the hydraulic cylinder piston rod 86 is matched with the hydraulic cylinder 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com