Test chamber tooth-meshing type quick-opening manhole

A quick-opening manhole and gear-toothed technology, which is applied to pressure vessels, engine seals, engine components, etc., can solve problems such as time-consuming and labor-intensive, long opening time, and low frequency of equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

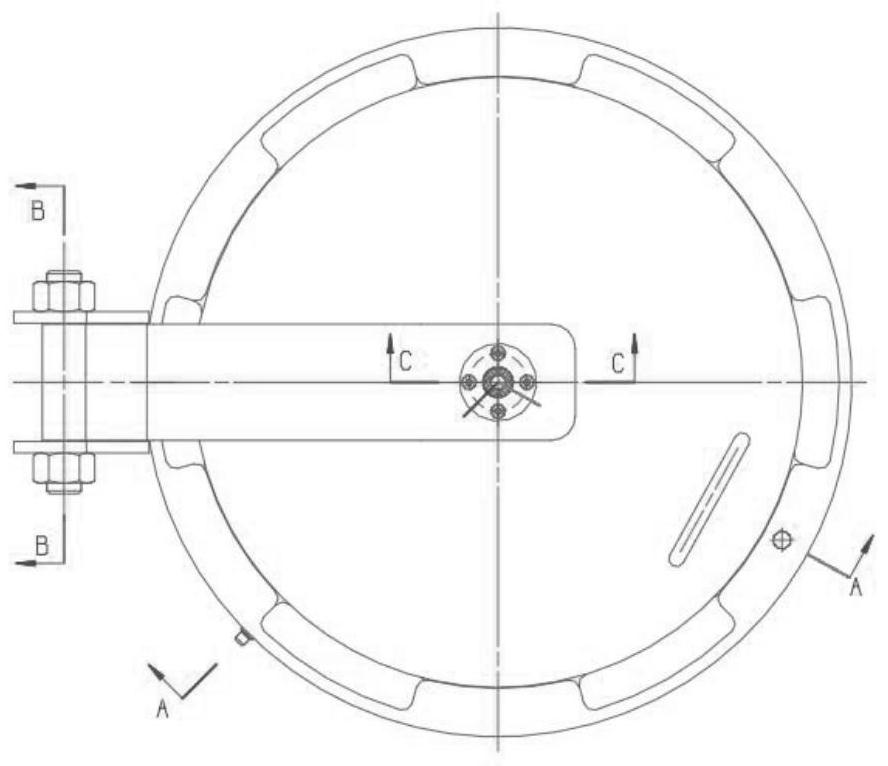

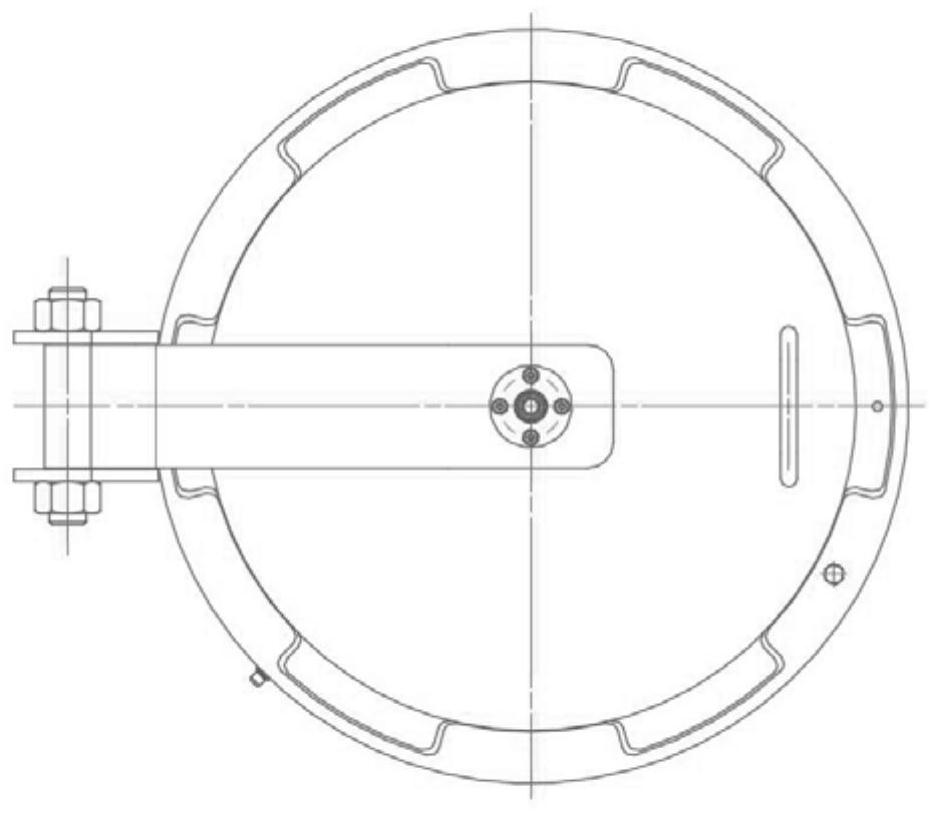

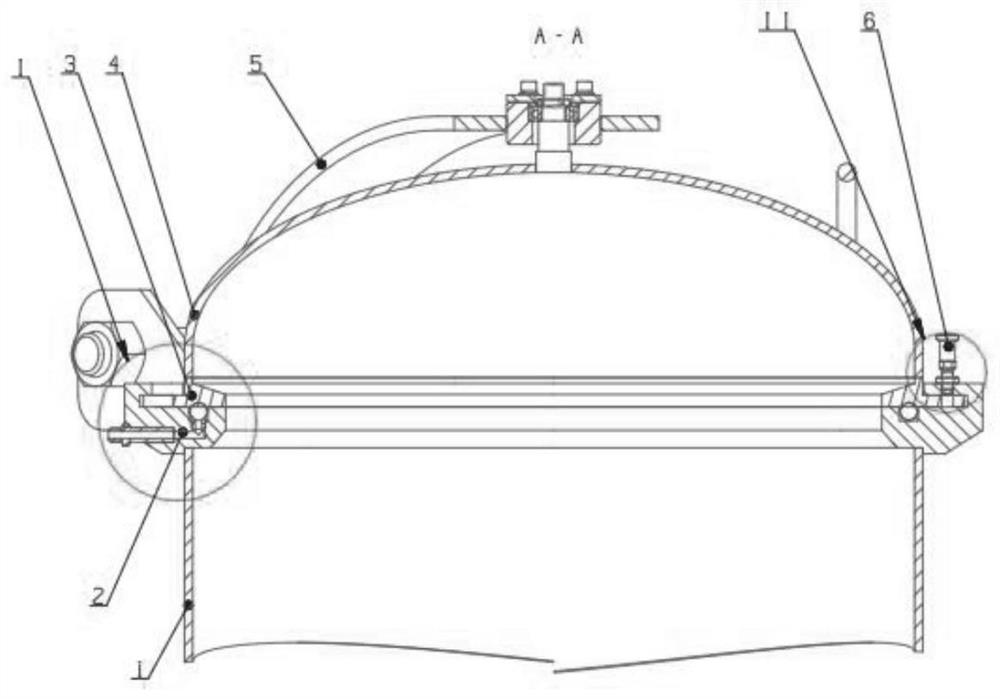

[0031] Such as Figure 1 to Figure 5 As shown in the figure, a toothed quick-opening manhole in a test cabin includes a cylinder body 1, a cylinder body flange 2, an ear plate 7 and a rotating shaft 8. The cylinder body 1, cylinder body flange 2 and ear plate 7 are welded and formed, and the rotating shaft 8 is inserted into the ear plate 7, and the two ends are fixed by nuts 15. It also includes the cover flange 3 and the cover body 4. The cover flange 3 and the cover body 4 are welded. The cover body 4 is provided with a fixed shaft 10, and the fixed shaft 10 A bearing-type rotatable mechanism is installed on it, and the bearing-type rotatable mechanism includes a deep groove ball bearing 16, a bearing seat 9 and a bearing end cover 11. The deep groove ball bearing 16 is arranged in the groove of the bearing seat 9 and is sleeved on the fixed shaft together. 10, the bearing end cover 11 is set above the bearing seat 9 to limit and compress the deep groove ball bearing 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com