A fault detection method and system

A fault detection and fault mode technology, which is applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, non-variable pumps, etc., can solve the problems of low precision, heavy workload and complexity of sample extraction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

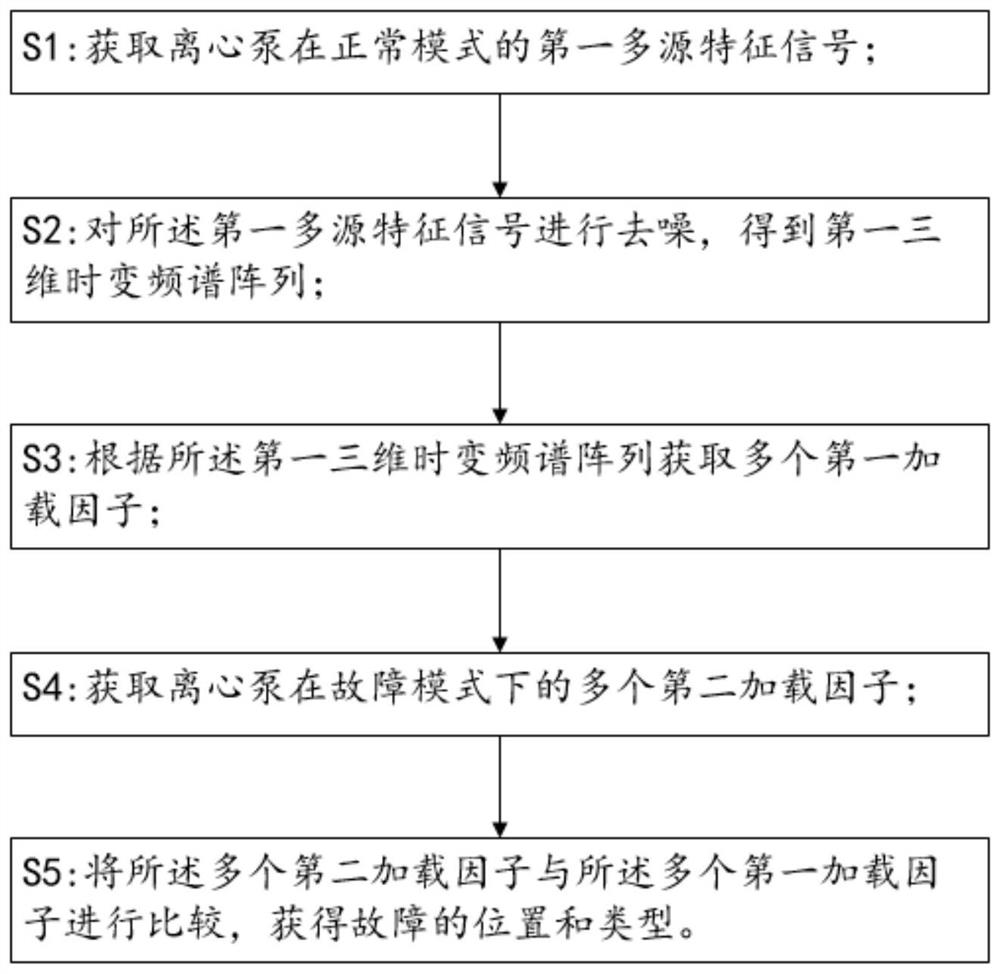

[0070] refer to figure 1 , a fault detection method comprising the following steps:

[0071] S1: Obtain the first multi-source characteristic signal of the centrifugal pump in normal mode;

[0072] S2: Denoising the first multi-source characteristic signal to obtain a first three-dimensional time-varying spectrum array;

[0073] S3: Obtain a plurality of first loading factors according to the first three-dimensional time-varying spectrum array;

[0074] S4: Obtain multiple second loading factors of the centrifugal pump in failure mode;

[0075] S5: Comparing the plurality of second loading factors with the plurality of first loading factors to obtain the location and type of the fault.

[0076] By obtaining the first multi-source feature of the centrifugal pump in normal mode, where the first multi-source feature refers to the signal features at different positions of the centrifugal pump, the first three-dimensional time-varying spectrum array is obtained after denoising, ...

Embodiment 2

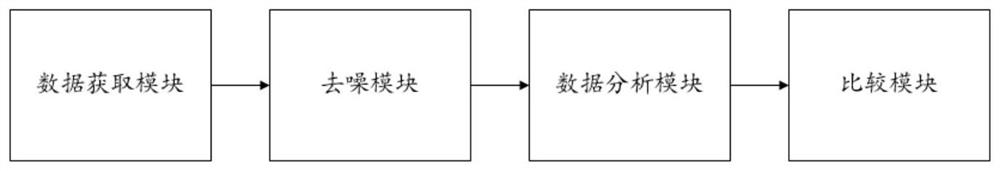

[0115] refer to figure 2 , on the basis of embodiment 1, a fault detection system, comprising: a data acquisition module, a denoising module, a data analysis module and a comparison module;

[0116] The data acquisition module is used to acquire the first multi-source characteristic signal of the centrifugal pump in normal mode and send it to the denoising module;

[0117] The denoising module is used to denoise the first multi-source characteristic signal, obtain a first three-dimensional time-varying spectrum array and send it to the data analysis module;

[0118] The data analysis module is used to obtain a plurality of first factor loads according to the first three-dimensional time-varying spectrum array and send them to the comparison module; load factors and send to said comparison module;

[0119] The comparison module is used to compare the plurality of second loading factors with the plurality of first loading factors, and output the location and type of the fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com