Coal Seam Hydraulic Reaming Drilling Tool and Reaming Technology

A hydraulic reaming and drilling tool technology, which is applied in directional drilling, earthwork drilling, drilling equipment, etc., can solve the problems of reporting, lack of coal seam hydraulic reaming drilling tools and reaming technology, and achieve improved gas drainage effect, Simple and applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

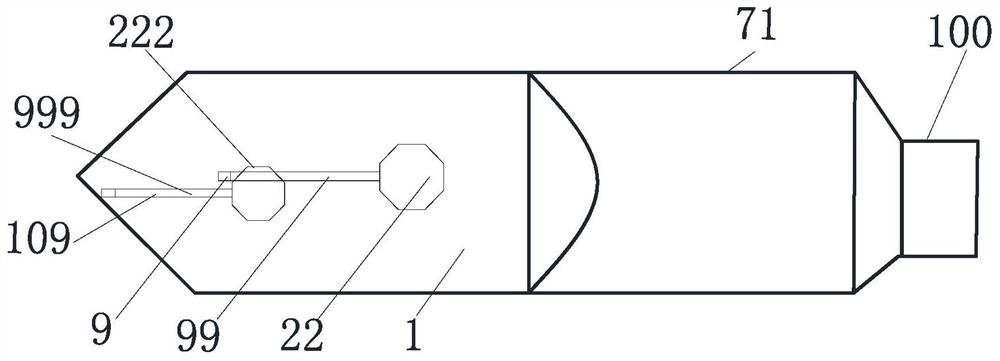

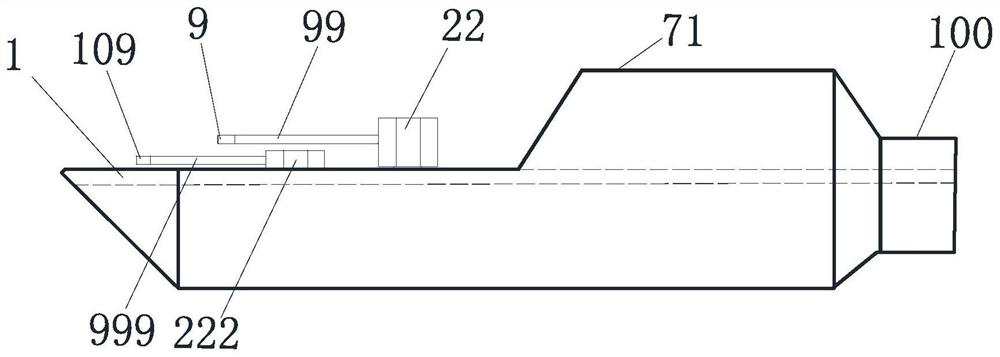

[0027] see Figure 1-Figure 5 , a coal seam hydraulic reaming drilling tool, including a drilling tool and a drill pipe joint 100, characterized in that: in the drilling tool shell 71, there is a hydraulic pump 80 with a hydraulic pump connection end 82 and a rack 90, and the rack 90 and the hollow drive The driving gear 20 on the gear bearing 21 is connected by transmission. After the hollow driving gear bearing 21 passes through the upper shaft hole of the thick steel frame 1, the outside of the drilling tool is fixed by the nozzle fixing bracket 22 on the hollow driving gear bearing. The inside of the drilling tool is driven by a hollow The gear bearing positioning part 210 is fixed on the thick steel frame 1 in a limited position, the upper shaft hole of the thick steel frame 1 is connected with the sliding bearing of the hollow drive gear bearing 21, and the connecting end 82 of the hydraulic pump is connected with the connecting end 211 of the hollow driving gear bearing ...

no. 2 example

[0030] see Figure 1-Figure 5, a coal seam hydraulic reaming drilling tool, including a drilling tool and a drill pipe joint 100, characterized in that: in the drilling tool shell 71, there is a hydraulic pump 80 with a hydraulic pump connection end 82 and a rack 90, and the rack 90 and the hollow drive The driving gear 20 on the gear bearing 21 is connected by transmission. After the hollow driving gear bearing 21 passes through the upper shaft hole of the thick steel frame 1, the outside of the drilling tool is fixed by the nozzle fixing bracket 22 on the hollow driving gear bearing. The inside of the drilling tool is driven by a hollow The gear bearing positioning part 210 is fixed on the thick steel frame 1 in a limited position, the upper shaft hole of the thick steel frame 1 is connected with the sliding bearing of the hollow drive gear bearing 21, and the connecting end 82 of the hydraulic pump is connected with the connecting end 211 of the hollow driving gear bearing w...

no. 3 example

[0036] see Figure 1-Figure 8 , a coal seam hydraulic reaming drilling tool reaming process, including drilling a drill hole 306 in the coal seam, using a high pressure water pump 308 to connect the drilling rig 307 with a conventional hydraulic reaming drilling tool 300 with a conventional nozzle 303 at the front end of the drilling machine 307 , use conventional hydraulic reaming drilling tool 300 water jet 302 conventional reaming 301 (general reaming radius 0.3 meters), pull out drill pipe 304, unload conventional hydraulic reaming drilling tool 300, the feature is: the drill pipe 304 passes through The drilling tool and the drill pipe joint 100 are connected to the coal seam hydraulic reaming drilling tool 400, and the nozzle rod 99 driven by the driving gear of the selected length is fixed on the nozzle fixing bracket 22 on the hollow driving gear bearing. The drill pipe 304 of the drilling tool 400 is inserted into the bottom of the hole, injecting high-pressure water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com