Microwave heating printing head for building 3D printing

A 3D printing and microwave heating technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of long hardening time of cement-based materials and easy collapse of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

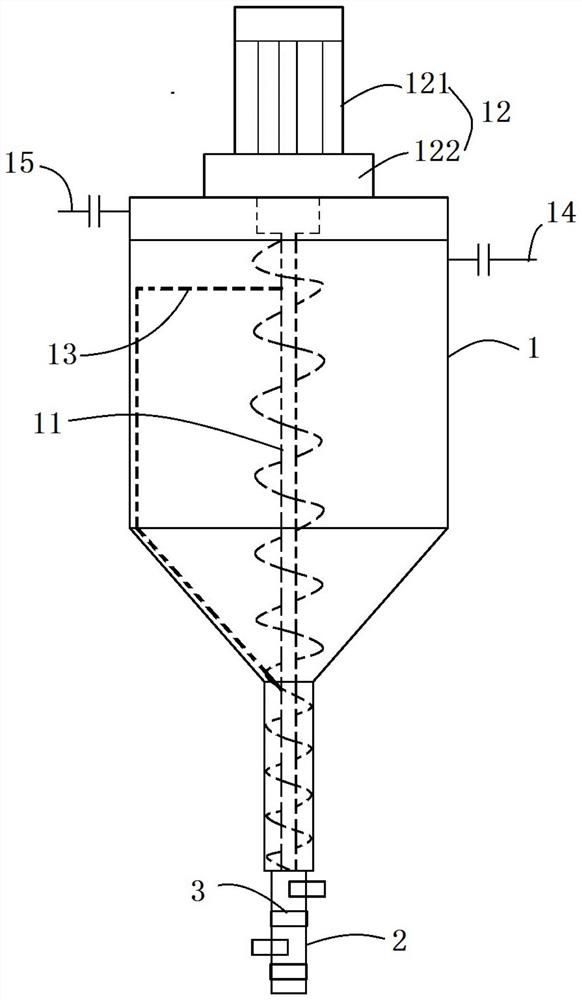

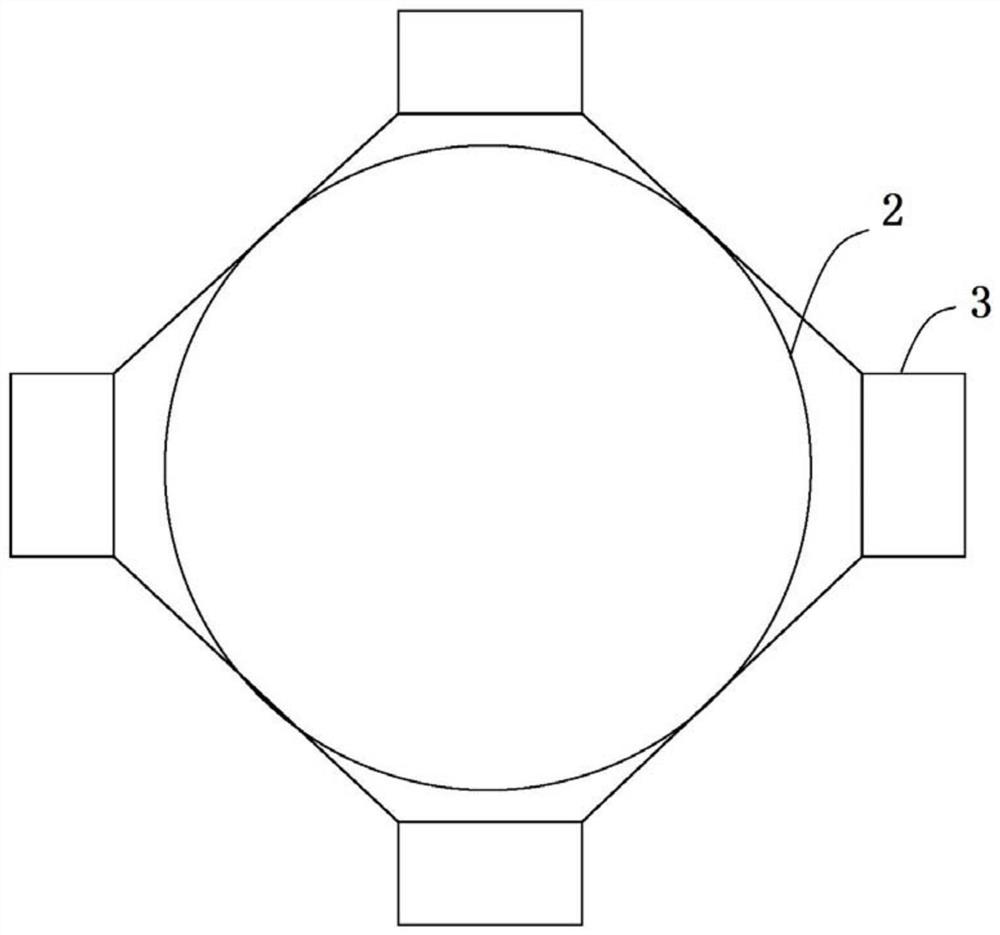

[0024] see figure 1 As shown, the present invention provides a microwave heating print head for building 3D printing, including a silo 1, a microwave-absorbable discharge pipe 2, a waveguide 3, a magnetron (not shown) and a power supply (not shown in the figure) Shown), the magnetron is a device used to generate microwaves. The magnetron generates microwaves under the action of an applied high-voltage current and transmits them to the waveguide. The tube is heated by microwaves, so that the printing material in the discharge tube is heated to accelerate hardening, shorten the hardening time, and avoid the collapse of the printed components.

[0025] Specifically, the interior of the bin 1 is formed with a space for accommodating printing materials, and the bottom of the bin 1 is formed with a discharge port;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com