Corner reinforcing part for constructional column formwork and formwork reinforcing method

A formwork reinforcement and reinforcement technology, which is applied to the connection parts of formwork/formwork/work frame, building structure, formwork/formwork/work frame, etc., can solve the problems such as difficult reinforcement of yin and yang corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples.

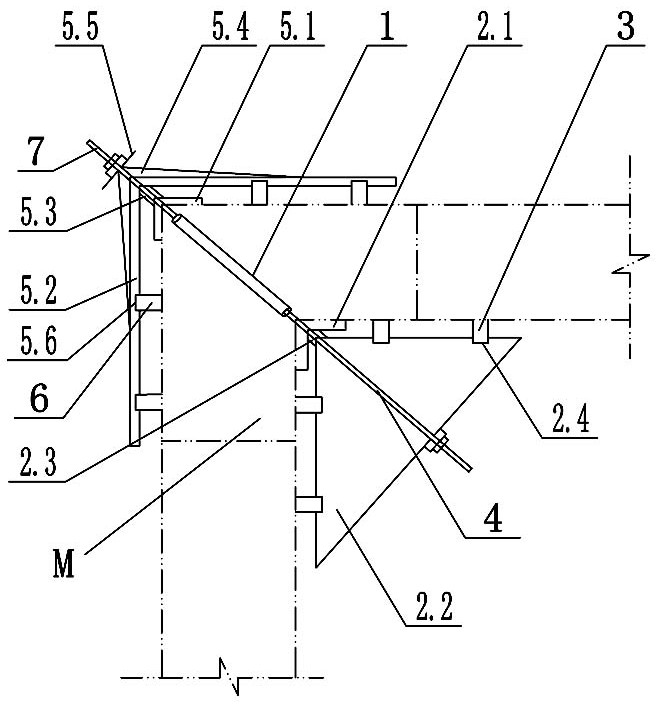

[0030] The corner stiffener used to construct the column template of the present invention can be used to press and fix the template of a variety of forms of construction column. figure 1 The illustrated L-shaped wall with structural columns is taken as an example for specific description.

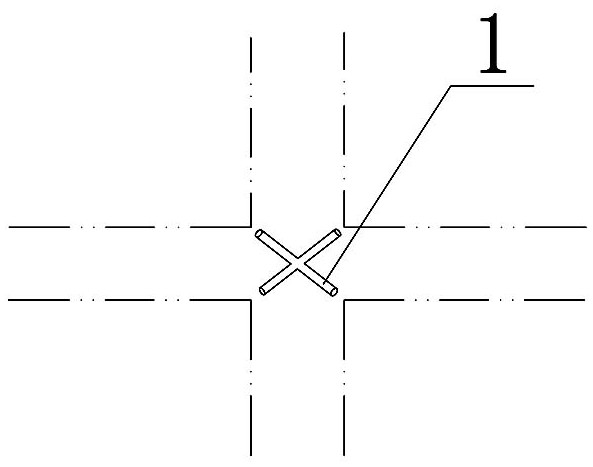

[0031] Such as figure 1 As shown, it includes an in-line embedded part 1 embedded in a structural column M, and both ends of which are provided with a plug-in cavity with internal threads. The central axis of the plug-in cavity is aligned with the angular apex of the structure column M. Correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com