Automatic logistics conveying line

A conveying line and logistics technology, applied in the direction of transmission, transportation and packaging, roller table, etc., can solve the problems of high design cost, transmission equipment without automatic sorting, complex structure of the device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

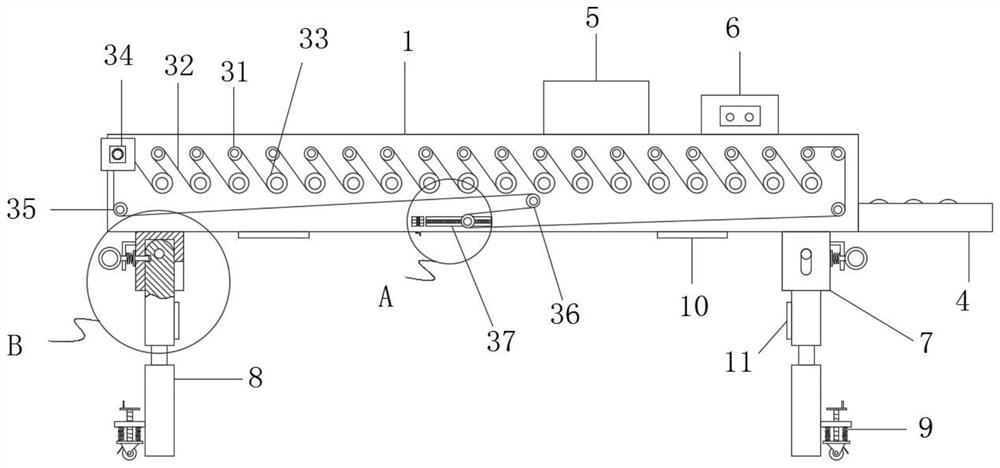

[0050] See attached figure 1 and 2 , the present invention provides a technical solution: an automatic logistics conveying line, including a frame 1, the cross section of the frame 1 is a U-shaped structure, and a conveying roller 2 is arranged to rotate in the frame 1, and there are a plurality of conveying rollers 2. Adjacent conveying rollers 2 are arranged at equal intervals, the front end of the central axis of the conveying roller 2 is connected with a roller synchronous transmission mechanism 3, the right side of the frame 1 is provided with a sorting device 4, and the right side of the rear side plate of the frame 1 is respectively A controller 5 and an identification module 6 are provided. The bottom end of the frame 1 is symmetrically provided with connecting seats 7. The connecting seats 7 on the same side are divided into two groups opposite to each other. Adjustment rollers 9 are arranged on the lower pipe wall, first magnets 10 are arranged symmetrically on the ...

Embodiment 2

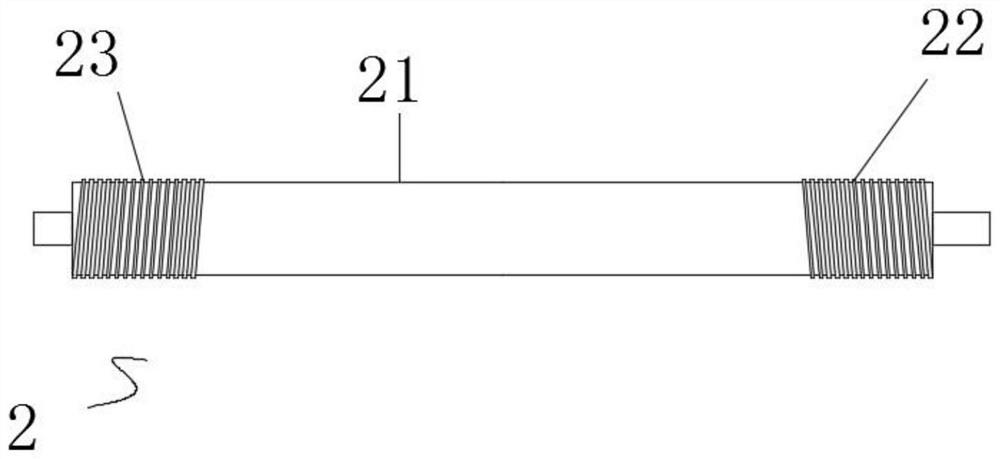

[0056] On the basis of embodiment 1, refer to the attached image 3 The conveying roller 2 includes a roller body 21, the right part of the roller body 21 is provided with a forward spiral 22, and the left part of the roller body 21 is provided with a reverse spiral 23, and the middle part of the forward spiral 22 and the reverse spiral 23 is smooth. When the cylinder body and the conveying roller 2 are normally conveyed, the cooperation of the forward spiral 22 and the reverse spiral 23 can make the conveyed goods on the conveying roller 2 tend to move towards the middle;

[0057] Specifically, because of the design of the positive and negative spirals, when the conveying roller 2 rotates under normal conditions, the positive and negative spirals will provide the force to move the goods to the middle, so when the goods are transported skewed, they can push the goods to the conveying rollers The middle part of the barrel, to avoid collision and friction between the goods and t...

Embodiment 3

[0059] On the basis of embodiment 1 or 2, refer to the attached figure 1 , the roller synchronous transmission mechanism 3 includes a first guide chain roller 31, a chain 32, a sprocket 33, a conveying motor 34, a second guide chain roller 35, a third guide chain roller 36 and a tensioning mechanism 37, 33 sets of sprockets Located at the front end of the central axis of the conveying roller 2, the first guide chain roller 31 is arranged on the front wall of the frame 1, and the first guide chain roller 31 is close to the top of the sprocket wheel 33, and there are four second guide chain rollers 35 in total. The upper and lower two are distributed at the four corners of the front side of the frame 1. The conveying motor 34 drives and connects the second guide chain roller 35 on the upper left, and there are two third guide chain rollers 36. The lower side of the middle part of the front side, the front side of the frame 1 is provided with a tensioning mechanism 37 near the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com