an injection mold

A technology for injection molds and moving molds, applied in the field of injection molds, can solve problems such as insufficient molding strength, ejection of molded parts, and decline in molding quality of injection molded parts, and achieve the effects of improving surface quality, ensuring integrity, and improving demoulding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

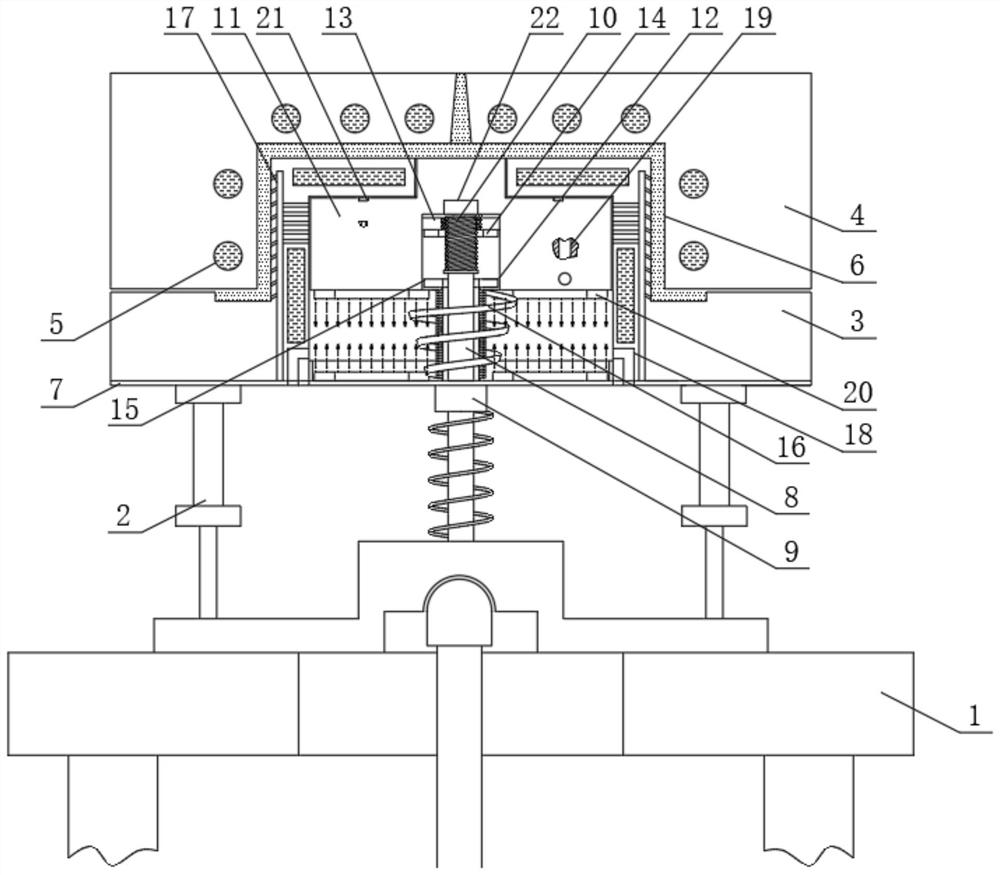

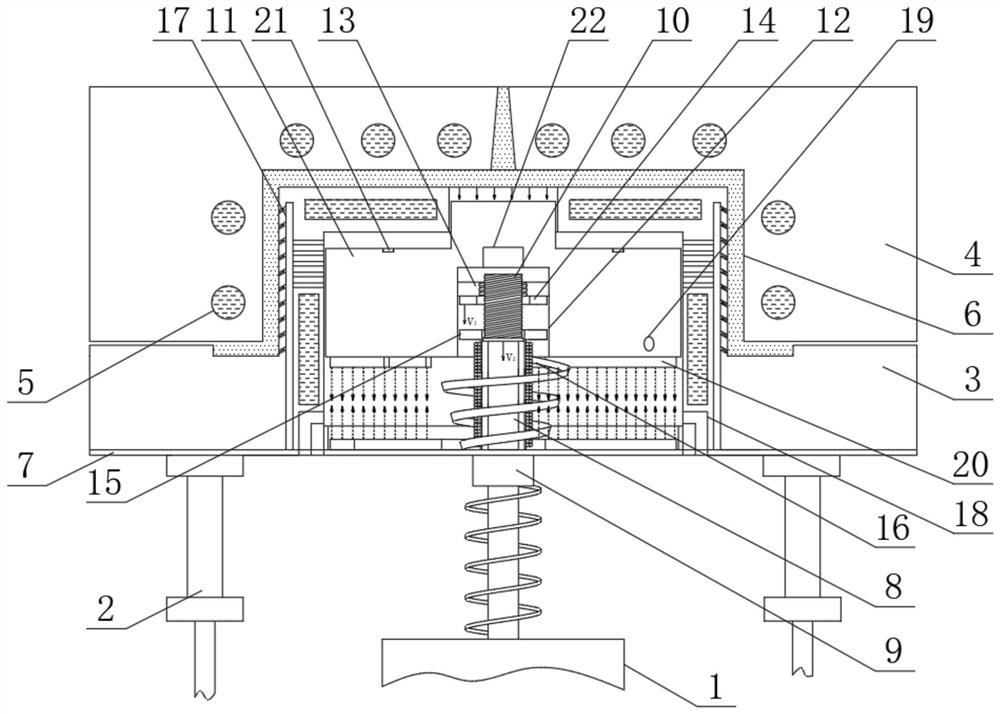

[0041] see Figure 1-11, an injection mold, including a hydraulic device 1, a hydraulic rod 2, a movable mold 3 and a fixed mold 4, the hydraulic device 1 and the movable mold 3 are connected by a hydraulic rod 2, and a mold is formed between the movable mold 3 and the fixed mold 4. Cavity 6, this mold cavity 6 can be set according to the different injection parts, the fixed mold 4 is provided with a cooling water channel 5, the middle of the fixed mold 4 is provided with a pouring port, the pouring port is communicated with the mold cavity 6 and the pouring port is connected to the injection molding machine, The middle of the movable mold 3 is opened in a groove shape and the groove is connected to the mold cavity 6, and the surrounding of the movable mold 3 is formed into a wall shape with a certain thickness. The air passage 17 communicates the cavity 6 with the groove of the movable die 3, and the bottom of the negative pressure air passage 17 extends to the outside of the...

Embodiment 2

[0052] Reference attached Figure 12 , Different from the first embodiment, a section of the driving rod 8 located inside the hollow electromagnet 15 can be hollow, and the middle of the driving rod 8 can be fixed with an iron core, so as to enhance the electromagnetic force of the hollow electromagnet 15, thereby ensuring Under the action of electromagnetic force, the seal 11 can move down, and the moving speed is faster than the moving speed of the movable mold 3, which ensures that in the case of demolding, its negative pressure is also generated at the same time, and the magnitude of the negative pressure is gradually changed. Sexual increase.

[0053] The principle of injection molding is as follows

[0054] Cooling forming stage:

[0055] After the injection molding machine injects the molten injection molding raw material into the mold cavity 6 through the injection port, the PLC controller controls the solenoid valve to open, and begins to inject cold water into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com