A high-speed, high-precision CNC edge folding machine and a method for solving the displacement of the edge folding beam

An edge folding machine, high-precision technology, applied in the direction of forming tools, instruments, manufacturing tools, etc., can solve the problems of difficult to guarantee machining accuracy, low efficiency, and influence of machining accuracy, and achieve intelligent control and simple kinematic inverse solution , precision and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

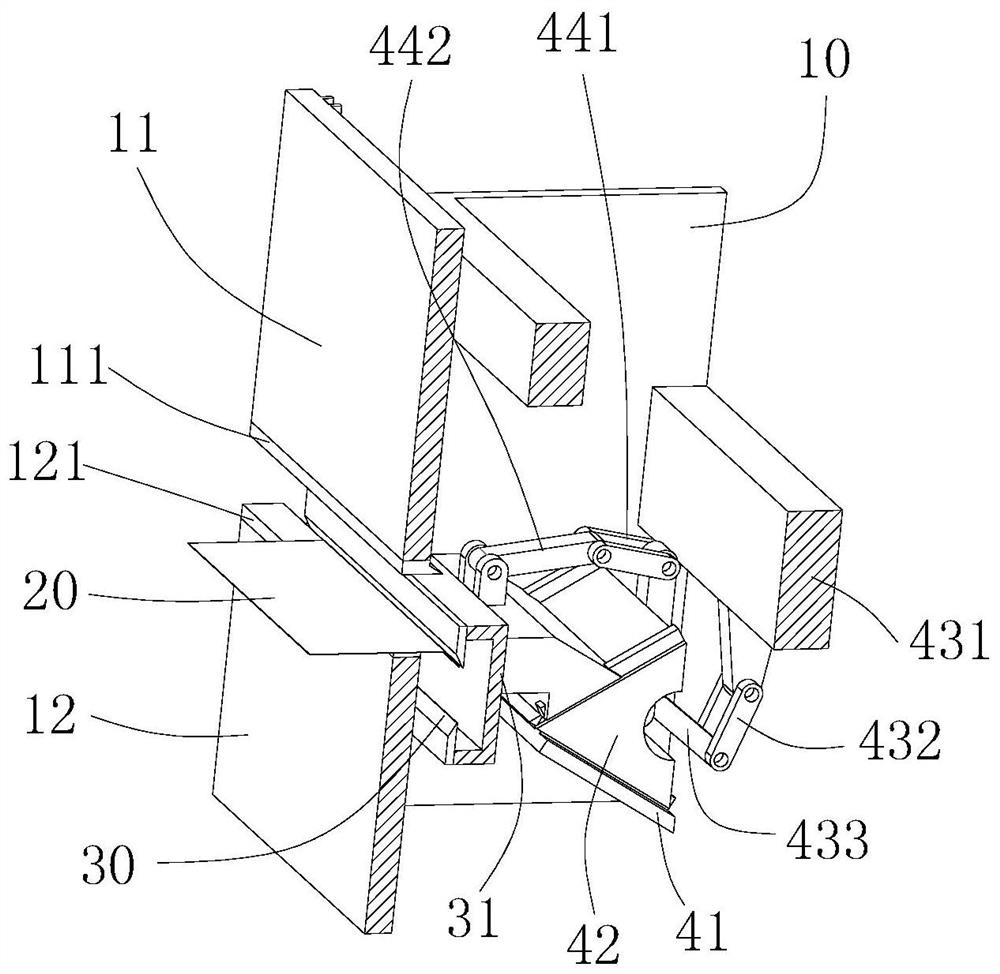

[0124] Example 1: as figure 1 and image 3 As shown in a, one end of connecting rod 1 is hinged with crank 1, and the other end of connecting rod 1 is hinged with driving seat.

Embodiment 2

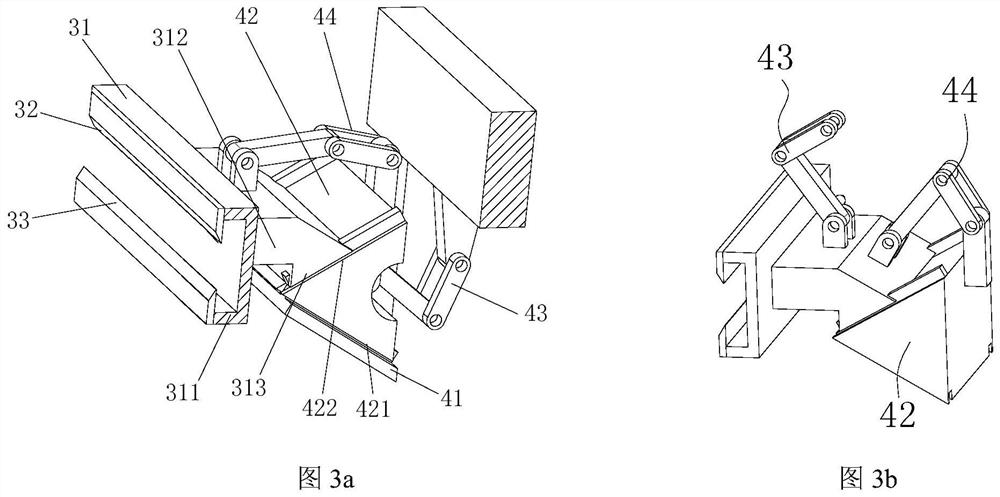

[0125] Example 2: as figure 2 and image 3 As shown in b, one end of the connecting rod 1 is hinged with the crank 1, and the other end of the connecting rod 1 is hinged with the folding beam. In this embodiment, the kinematic inverse solution is simpler, and the sliding auxiliary load of the guide is smaller.

[0126] In the present invention, the connecting rod transmission of the first crank-link mechanism preferably has the following two driving modes.

[0127] Driving mode 1: A servo motor 1 is preferably arranged on the frame to drive the rotation of the crank 1.

[0128] Driving mode 2: The connecting rod transmission of the first crank connecting rod mechanism is driven by the toggle lever mechanism. The specific setting method is as follows: the toggle lever mechanism is hingedly installed at the hinge point where the crank 1 and the connecting rod 1 are hinged, and the hinge point is called the hinge point. Drive hinge point.

[0129] Wherein, the toggle mechani...

Embodiment 3

[0153] Embodiment 3, horizontal movement

[0154] Through the nonlinear coupling drive (compound drive) of the first crank drive mechanism and the second crank drive mechanism, the driving process is as follows Figure 7 As shown, the horizontal translation movement can be realized.

[0155] During the horizontal translation process, the displacement X and displacement Y of the folded beam can be solved analytically through the real-time readings of the two grating rulers. The displacement movement process of the two cursor rulers, such as Figure 9 a shown.

[0156] like Figure 10 As shown in the figure, a method for solving the displacement of the folded beam, the folded beam solves its own displacement through two sets of grating scales, and the specific solution method includes the following steps.

[0157] Step 1. Establish the coordinate system and the linear equation of the grating ruler, including the following steps.

[0158] Step 11. Establish a coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com