Stationary visual screening system

A technology of conveyor belts and components, applied in the field of waiting visual sorting system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing description:

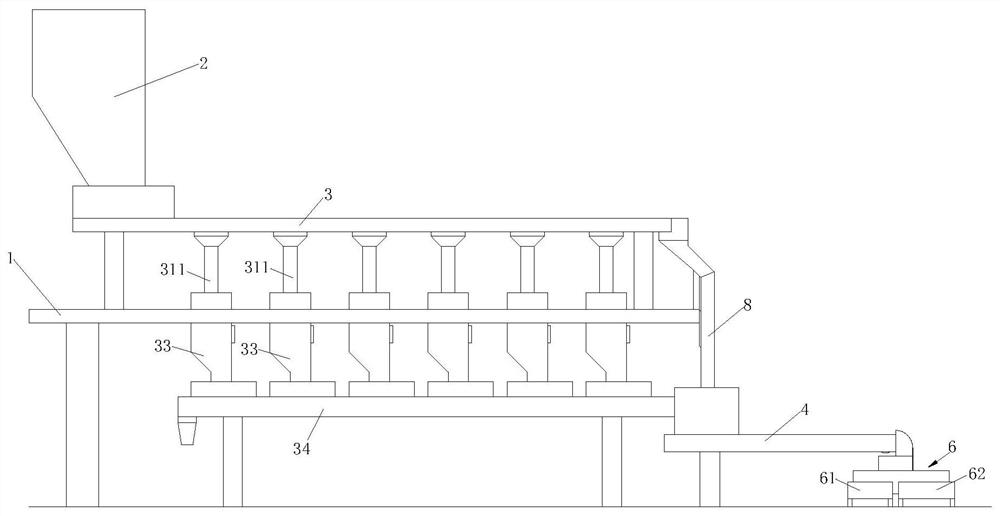

[0034] Such as Figure 1-10 As shown, the present invention is a kind of waiting visual sorting system, which is characterized in that: it includes a frame 1, a feed storage bin 2 fixedly installed on the frame 1, a storage bin 2 installed on the frame 1 and connected to the feed material The object selection device 3 connected to the discharge port of the storage bin 2;

[0035] Described purpose selection device 3 comprises the purpose selection frame 31 that is fixedly installed on the frame 1, and described purpose selection frame 31 is installed with relative purpose selection frame 31 along transverse direction cycle and moves repeatedly to transport material. Conveyor belt assembly 32, the unqualified material conveyor belt assembly 34 that is located below the purpose selection conveyor belt assembly 32 and can move repeatedly along the transverse directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com