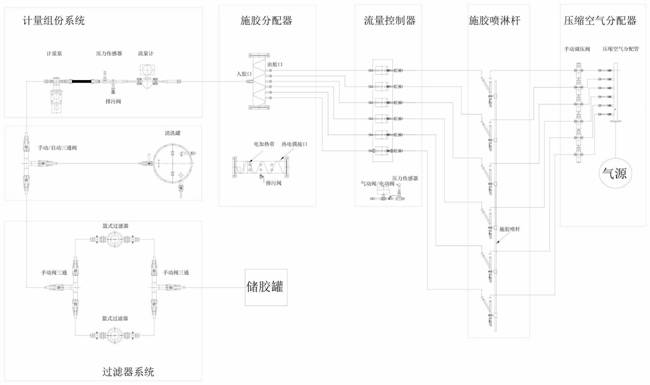

Atomization sizing system process of a roller glue mixer

The technology of a roller glue mixing machine and glue mixing machine is applied in the directions of spraying device, coating, liquid spraying device, etc., which can solve the problems of increasing the consumption of glue, large equipment investment, uneven distribution of glue on the board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The process of the atomization sizing system of the drum glue mixing machine includes the following steps:

[0033]Step 1: The glue storage tank storage system uses multiple glue storage tanks to store the glue; there can be multiple glue storage tanks, which are connected to the hanging weighing type glue buffer tank, and the hanging type weighing type glue buffer tank is connected to the Filter system connection.

[0034] The second step: the filter system, which includes a 1-3 cubic hanging weighing buffer tank, the buffer tank is equipped with a hanging weighing device and a temperature-controlled heating heating cable. Two blue filters (one for use and one for backup) are used to filter the colloid; the filter system also includes a manual or automatic three-way valve, and the hanging weighing glue buffer tank is connected to the blue-type filter through the manual or automatic three-way valve. The filter is connected, and can be switched manually or automatically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com