Preparation method of high-flux polytetrafluoroethylene composite nanofiltration membrane

A technology of polytetrafluoroethylene and composite nanofiltration membrane, which is applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as clogging and reduction of water flux of composite nanofiltration membrane, so as to improve filtration efficiency and improve water quality. Flux, breakage-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

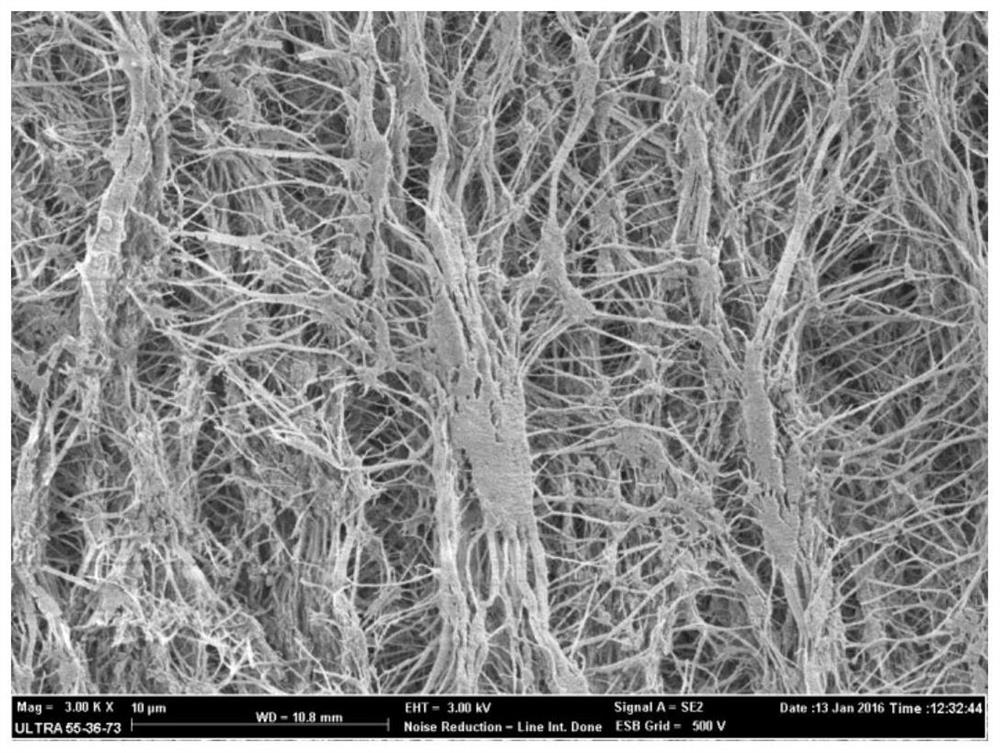

Image

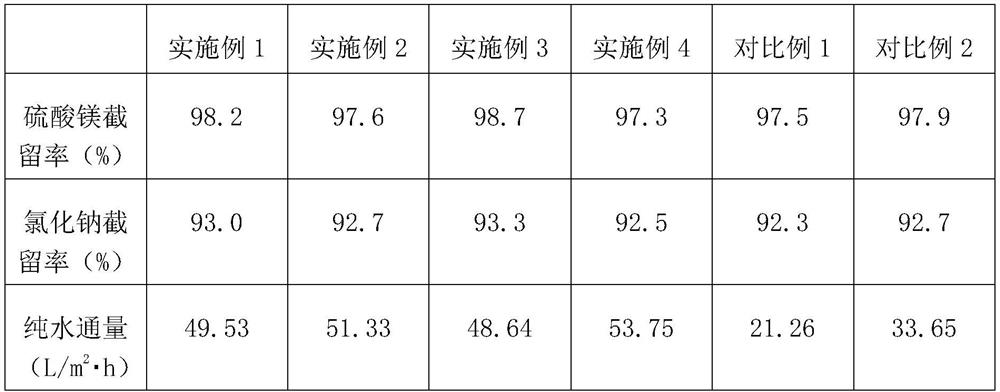

Examples

Embodiment 1

[0024] The preparation method of high flux polytetrafluoroethylene composite nanofiltration membrane comprises the following steps:

[0025]S1. Measure equal volumes of deionized water and absolute ethanol and mix them to obtain a mixed solution of deionized water and ethanol. Add sodium alginate to the mixed solution of deionized water and ethanol to prepare a sodium alginate solution with a mass concentration of 4.0%. , add dropwise a hydrochloric acid solution with a concentration of 0.5mol / L to the sodium alginate solution to adjust the pH to 5, immerse the hydrophobic polytetrafluoroethylene microporous membrane in the sodium alginate solution, and then add glutaraldehyde crosslinking agent, glutaraldehyde The amount of aldehyde added is 3.5wt% of sodium alginate, heated to 50°C in a water bath, kept for 2.5 hours, and then placed in an oven and dried at 50°C to obtain an activated hydrophilic polytetrafluoroethylene microporous membrane;

[0026] S2. Add quartz glass fib...

Embodiment 2

[0031] The preparation method of high flux polytetrafluoroethylene composite nanofiltration membrane comprises the following steps:

[0032] S1. Measure equal volumes of deionized water and absolute ethanol and mix them to obtain a mixed solution of deionized water and ethanol, add sodium alginate to the mixed solution of deionized water and ethanol to prepare a sodium alginate solution with a mass concentration of 2.0% , add dropwise a hydrochloric acid solution with a concentration of 0.5 mol / L to the sodium alginate solution to adjust the pH to 4, immerse the hydrophobic polytetrafluoroethylene microporous membrane in the sodium alginate solution, and then add glutaraldehyde crosslinking agent, glutaraldehyde The amount of aldehyde added is 3.5wt% of sodium alginate, heated to 60°C in a water bath, kept for 2 hours, and then dried in an oven at 50°C to obtain an activated hydrophilic polytetrafluoroethylene microporous membrane;

[0033] S2. Add quartz glass fiber and silan...

Embodiment 3

[0038] The preparation method of high flux polytetrafluoroethylene composite nanofiltration membrane comprises the following steps:

[0039] S1. Measure equal volumes of deionized water and absolute ethanol and mix them to obtain a mixed solution of deionized water and ethanol, add sodium alginate to the mixed solution of deionized water and ethanol to prepare a sodium alginate solution with a mass concentration of 5.0% , add dropwise a hydrochloric acid solution with a concentration of 0.5mol / L to the sodium alginate solution to adjust the pH to 4.5, immerse the hydrophobic polytetrafluoroethylene microporous membrane in the sodium alginate solution, and then add glutaraldehyde crosslinking agent, glutaraldehyde The amount of aldehyde added is 3.5wt% of sodium alginate, heated to 55°C in a water bath, kept for 3 hours, and then placed in an oven and dried at 50°C to obtain an activated hydrophilic polytetrafluoroethylene microporous membrane;

[0040] S2. Add quartz glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com