Miniature array ultrasonic transducer, preparation method thereof, and ultrasonic probe including miniature array ultrasonic transducer

An ultrasonic transducer and microarray technology, which is applied in ultrasonic/acoustic/infrasonic diagnosis, ultrasonic diagnosis, infrasonic diagnosis, etc., can solve the problems of complex product structure and preparation process, poor ultrasonic imaging performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

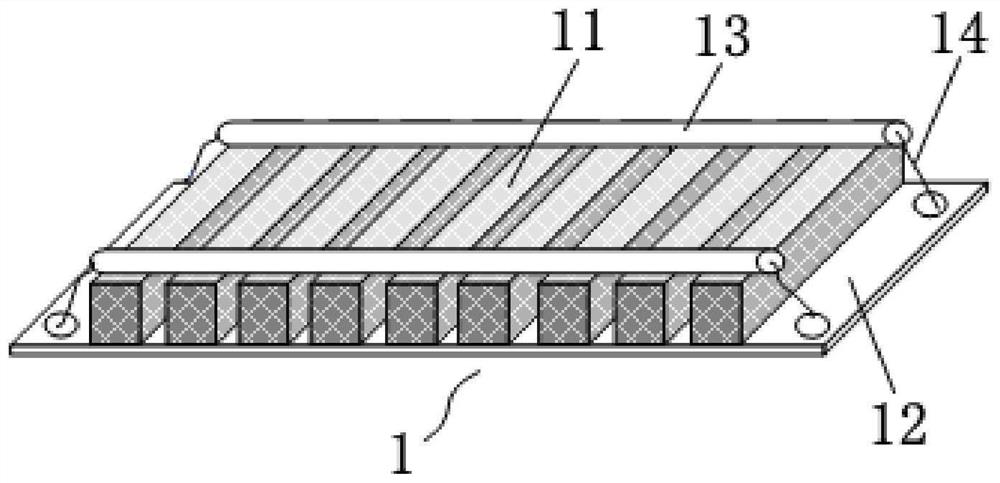

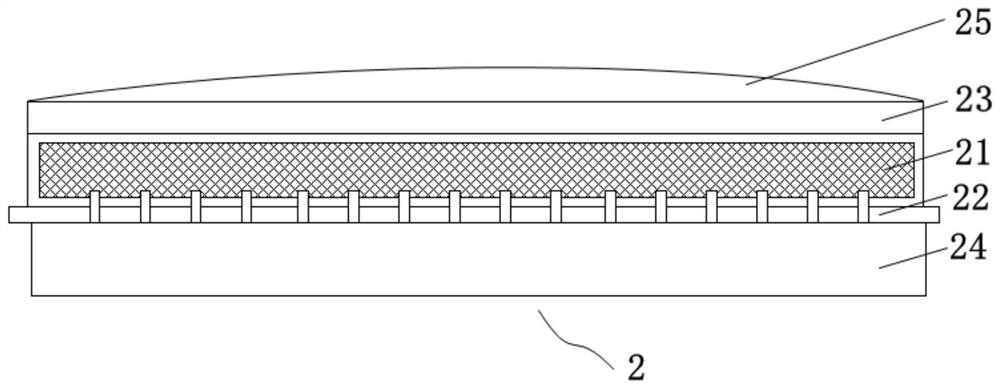

[0066] The present embodiment provides a microarray ultrasonic transducer 2, such as figure 2 As shown, it includes a piezoelectric wafer 21 , a flexible circuit board 22 , an acoustic matching layer 23 , a backing layer 24 and an acoustic lens layer 25 .

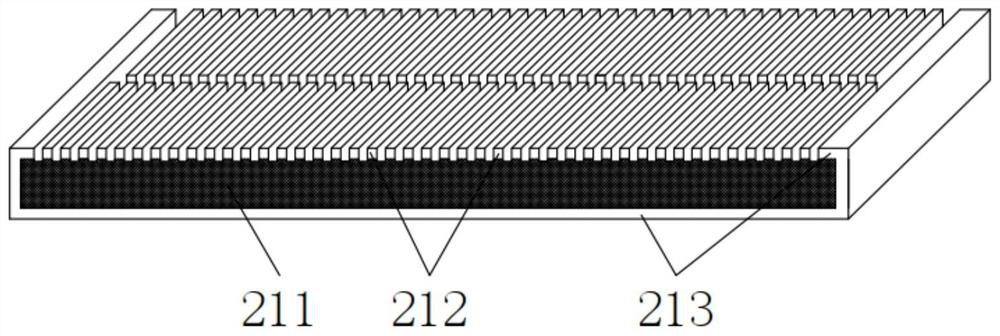

[0067] The piezoelectric chip 21 is the core component of the micro-array ultrasonic transducer 2. After receiving the voltage, it generates vibration and outputs ultrasonic waves. The parameters such as the shape, material, and thickness of the piezoelectric chip 21 directly affect the performance of the micro-array ultrasonic transducer 2. , which in turn determines the quality of ultrasound imaging. Such as image 3 As shown, the piezoelectric wafer 21 includes a piezoelectric material layer 211 , a first piezoelectric electrode 212 and a second piezoelectric electrode 213 .

[0068] The shape of the piezoelectric material layer 211 can be selected from geometric shapes such as rectangle, circle, and ellipse, and its ...

Embodiment 2

[0079] This embodiment provides a method for preparing the microarray ultrasonic transducer as described in Embodiment 1, such as Figure 8 shown, including the following steps:

[0080] The first step is to prepare a piezoelectric wafer with an edge wrapping structure

[0081] Continuous conductive sheets are arranged on both surfaces and part of the edges of the piezoelectric material layer 211 to form a piezoelectric wafer 21 with an edge wrapping structure. Specifically, on the upper and lower surfaces and two short sides of the rectangular 1-3 type piezoelectric composite material, a continuous conductive sheet is provided by evaporation, electrochemical deposition, magnetron sputtering, etc., and the conductive sheet only covers The two short sides and the two long sides of the piezoelectric material layer 211 are not provided with conductive sheets, that is, a piezoelectric chip 21 with a double-side wrapping structure is formed. In this embodiment, vapor deposition i...

Embodiment 3

[0096] This embodiment provides another preparation method of the microarray ultrasonic transducer as described in Embodiment 1, such as Figure 9 shown, including the following steps:

[0097] The first step is to prepare a piezoelectric wafer with an edge wrapping structure

[0098] Continuous conductive sheets are arranged on both surfaces and part of the edges of the piezoelectric material layer 211 to form an edge-wrapped piezoelectric wafer 21 . Specifically, on the upper and lower surfaces and two short sides of the rectangular 1-3 type piezoelectric composite material, a continuous conductive sheet is provided by evaporation, electrochemical deposition, magnetron sputtering, etc., and the conductive sheet only covers The two short sides and the two long sides of the piezoelectric material layer 211 are not provided with conductive sheets, that is, a piezoelectric chip 21 with a double-side wrapping structure is formed. In this embodiment, vapor deposition is used.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com