Displacement Control Method of Magnetically Controlled Shape Memory Alloy Actuator

A memory alloy, displacement control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of unknown system parameters, complex hysteresis dynamic characteristics of magnetic control shape memory alloy actuators, and restricted application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

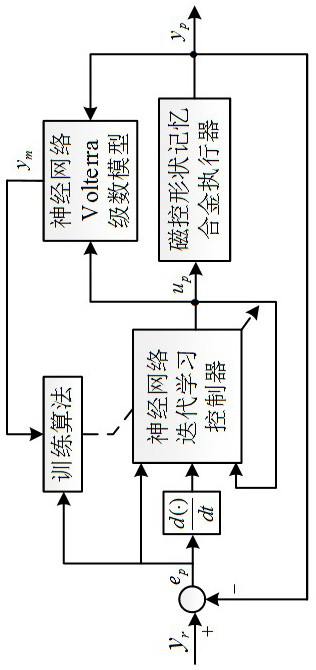

[0050]A method for controlling the displacement of a magnetically controlled shape memory alloy actuator based on neural network iterative learning control provided by the present invention is characterized in that it comprises the following steps:

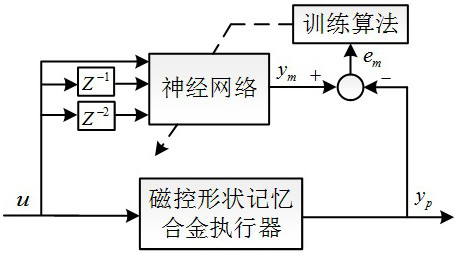

[0051] Step 1: Establish a Volterra series model that can describe the rate-dependent hysteresis nonlinearity of the magnetically controlled shape memory alloy actuator, and use the neural network to construct the kernel function of the Volterra series;

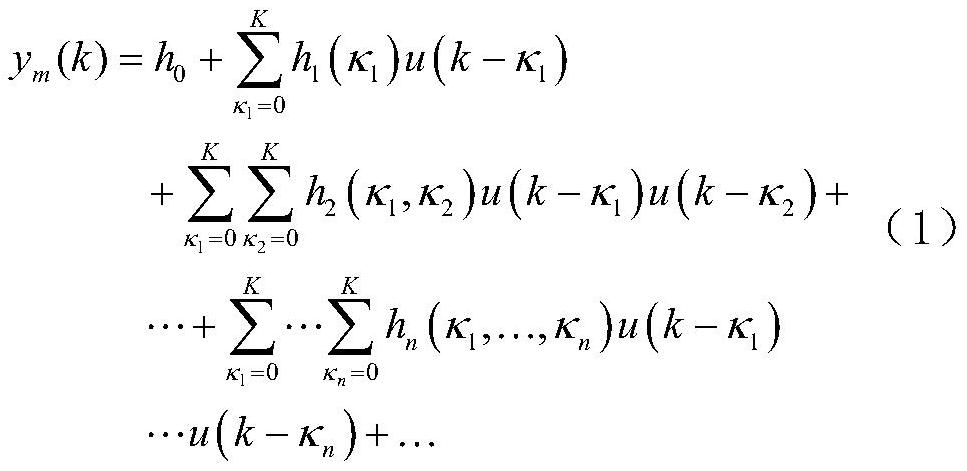

[0052] The expression of the Volterra series model is:

[0053]

[0054] Among them, k=0,1,...,N-1 is the discrete time, N is the expected time length and is a positive integer, n is the order of the model, p is the number of iterations, u p (k) and is the input and output values of the model at the pth iteration, h n (κ 1 ,...,κ n ) and K is the nth order kernel function and memory length of the model, κ n is the memory delay corresponding to the nth item.

[0055] C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com