High-voltage cable joint internal defect detection method based on X-ray imaging technology

A high-voltage cable and internal defect technology, which is applied in the direction of material analysis using radiation, can solve the problems of inability to detect internal defects of cable joints, low detection accuracy, and difficulty in detecting cable intermediate joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

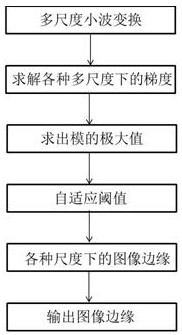

[0041] like Figure 1-2 As shown, this embodiment provides a method for detecting internal defects of high-voltage cable joints based on X-ray imaging technology, including the following steps:

[0042] S1: Use the Maya model of the internal structure of the high-voltage cable joint to preprocess the original X-ray images;

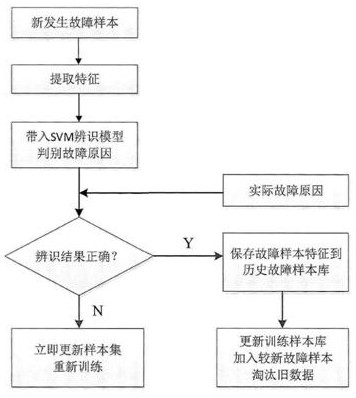

[0043] S2: Use the typical defect map model of the internal structure of high-voltage cable joints to extract the characteristic information of internal typical defects;

[0044] S3: Adopt the intelligent detection expert system for internal faults of high-voltage cable joints to accurately identify and locate X-ray pictures, and detect and diagnose the status of high-voltage cable joints.

[0045] The maya model is a three-dimensional maya model.

[0046] The preprocessing adopts a spatial domain filtering method to perform filter enhancement processing.

[0047] Described spatial domain filter method is processed by template, promptly utilizes templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com