Diesel engine lubricating system testing device and testing method

A technology of lubricating system and testing device, applied in lubrication indicating device, engine measuring device, pressure lubricating safety device, etc., can solve the problem of inability to determine the oil flow of diesel engine lubrication system, lack of quantitative data of oil flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the invention.

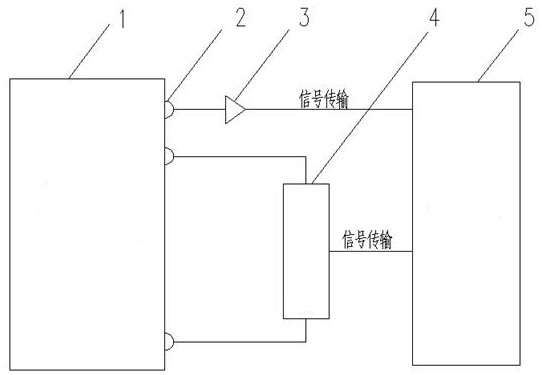

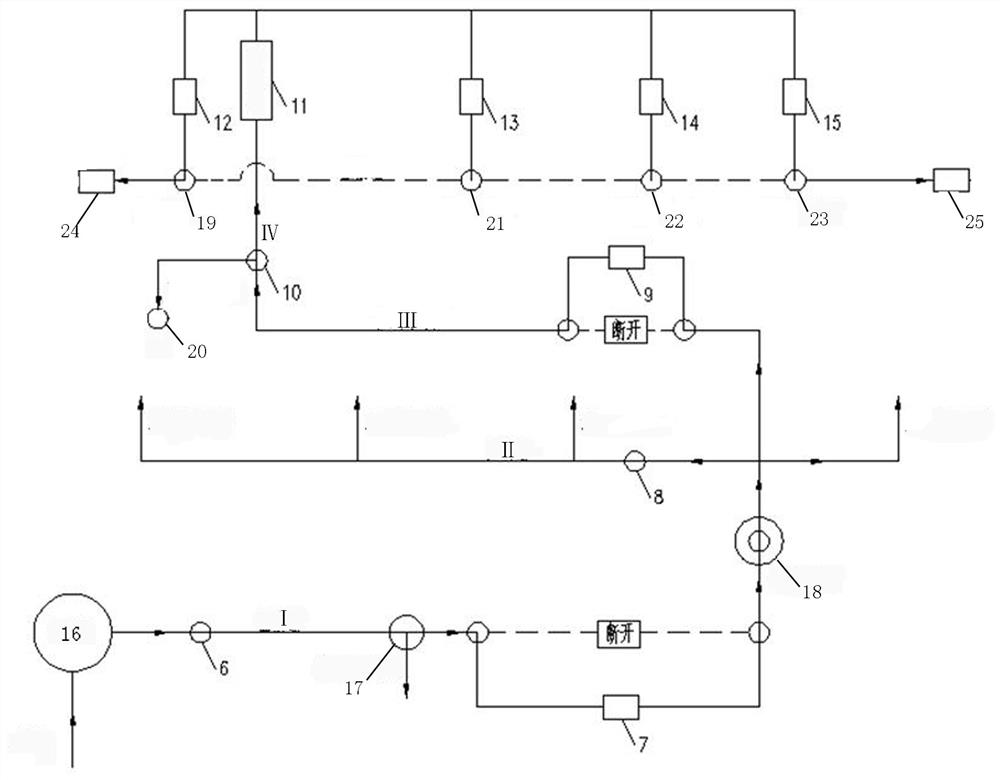

[0021] Refer to the attached figure 1 As shown, a diesel engine lubrication system testing device includes a test diesel engine body 1 and a test bench 5. The test bench adopts an eddy current dynamometer whose model is GWD250. The different positions of the test diesel engine body 1 on the oil circuit are respectively The installation hole is opened, and the transition joint 2 is fixed on the installation hole. The transition joint 2 is connected with the oil circuit in the test diesel engine body 1, and in order to ensure the tightness, a sealant is smeared between the transition joint 2 and the test diesel engine body 1 . The temperature and pressure sensors 3 for measuring the temperature and pressure of the oil are installed on the transition joint 2 one-to-one, and the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com