Arc-shaped line construction formwork structure

A technology of lines and templates, applied in the direction of formwork/formwork components, formwork/formwork/work frames, building structures, etc., can solve problems such as many repairing and polishing processes, improving construction progress, and increasing construction input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

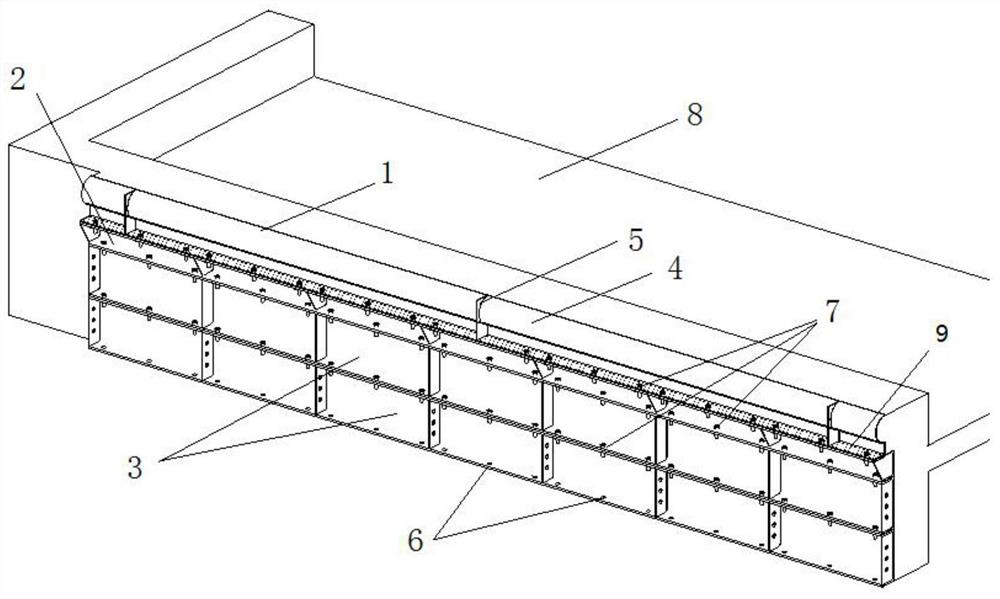

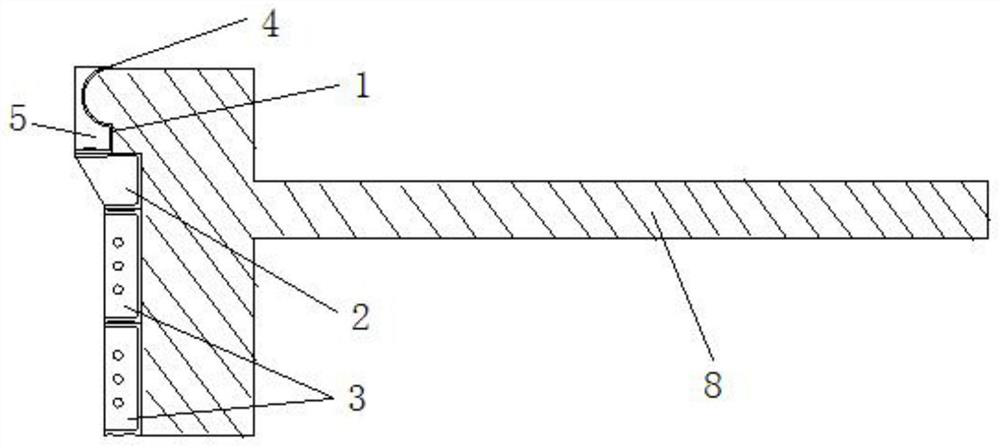

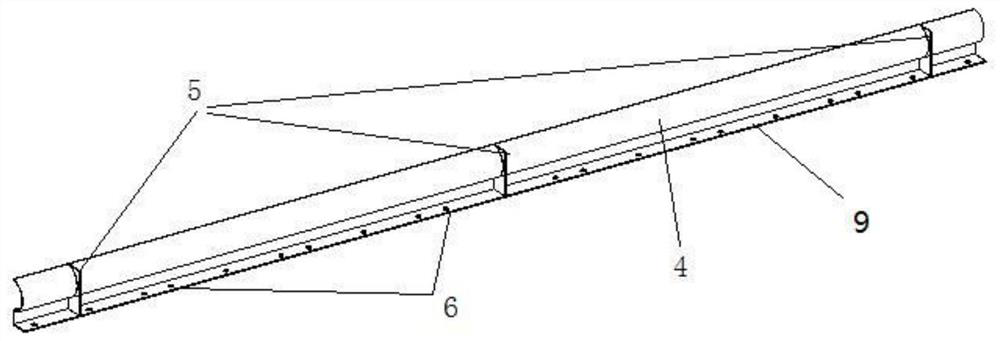

[0014] refer to Figure 1 to Figure 5 , the present invention provides an arc-shaped line construction formwork structure, including a semicircular arc-shaped steel formwork 1, a C-shaped aluminum formwork 2 at the inner corner, a U-shaped aluminum formwork 3 at the beam side, and a C-shaped aluminum formwork at the inner corner. Both the aluminum formwork 2 and the beam-side U-shaped aluminum formwork 3 are provided with pin holes 6, and the pin holes 6 are correspondingly provided with pins 7 for fixing the formwork to the outside of the cast-in-place balcony 8. The semicircular arc-shaped steel formwork 1 includes along the The shaped steel plate 4 arranged horizontally and with a semicircular arc-shaped longitudinal section and the connecting plate 9 connected and fixed on the lower side of the shaped steel plate 4 along the transverse direction, the lower side of the connecting plate 9 is fitted and fixed on the upper part of the C-shaped aluminum formwork 2 at the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com