Steel-concrete composite beam structure, building and construction method

A technology of concrete and composite beams, which is applied to building structures, buildings, building components, etc., and can solve problems such as complex construction, complex construction technology, and large steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

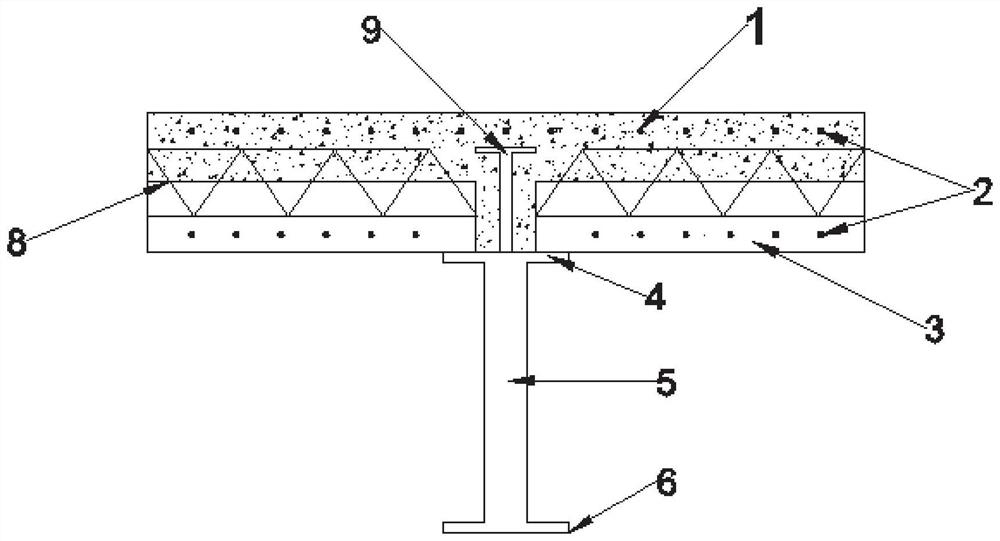

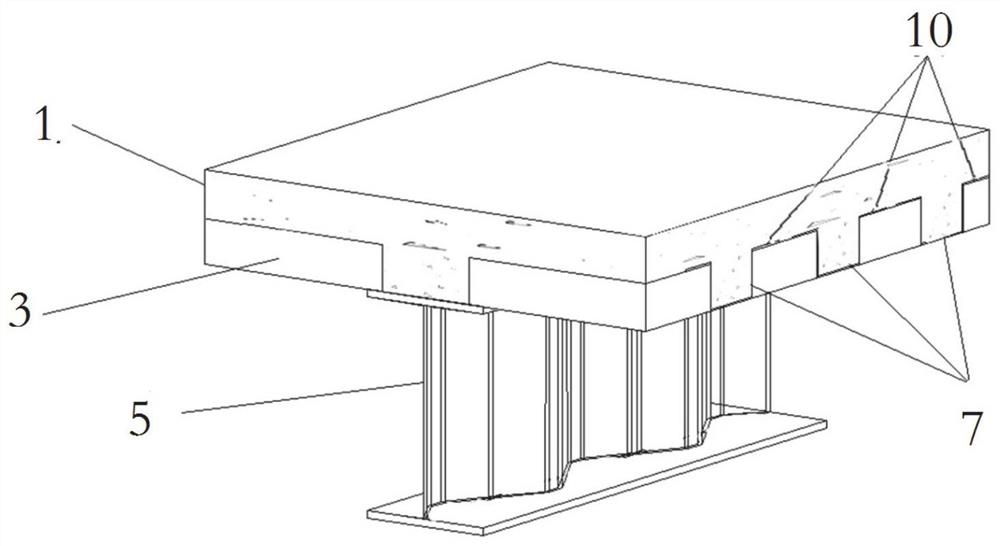

[0029] Such as Figure 1-5 As shown, this embodiment provides a steel-concrete composite beam structure, including a corrugated web steel girder, the upper surface of the upper flange of the corrugated web steel girder is lapped with a prefabricated slab 3, and a joint 7 is formed between adjacent prefabricated slabs 3 Concrete is poured in the joint 7, and the adjacent prefabricated slabs 3 are connected by lap steel bars 11 and profiled steel plates 10. The upper end surface of the prefabricated slab 3 is provided with a post-cast layer 1, and the post-cast layer 1 is formed with the precast slab 3. Composite plate structure; a profiled steel plate 10 is arranged in the joint 7 , and the bottom surface of the profiled steel plate 10 is flush with the lower end surface of the prefabricated plate 3 to receive the concrete in the joint 7 .

[0030] It should be pointed out that in this embodiment, the overlapping steel bars can be bound by wire ropes or pulled by U-shaped steel...

Embodiment 2

[0044] This embodiment provides a construction method for a steel-concrete composite beam structure, comprising the following steps:

[0045] Step 1, fix the corrugated web steel girder, and weld the fixed shear connector on the upper flange;

[0046] Step 2, the prefabricated slab 3 is lapped on the upper surface of the upper flange of the corrugated web steel girder, the prefabricated slab 3 is supported by the preset bracket, and a certain length of lapped steel bars is reserved at the splicing part of the adjacent prefabricated slabs, and the lapped The position of the steel bar is also the joint position between adjacent prefabricated panels. And place profiled steel plates at the seams to connect the two prefabricated panels. The width of the bottom plate of the profiled steel plate is the same as that of the seam, the height of the left and right webs is the same as that of the prefabricated slab, and the length is the same as the span of the prefabricated slab. And the...

Embodiment 3

[0053] This embodiment provides a building using the steel-concrete composite beam structure described in Embodiment 1. The building in this embodiment can be a bridge or a prefabricated house, etc., and those skilled in the art can choose the application occasion of the composite beam by themselves, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com