A Concrete Inner Vibration Casting Technology

A technology of concrete inside and concrete, applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of non-vertical vibrating rods, slow insertion, poor concrete vibration effect, etc., and achieve the effect of easy bonding and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

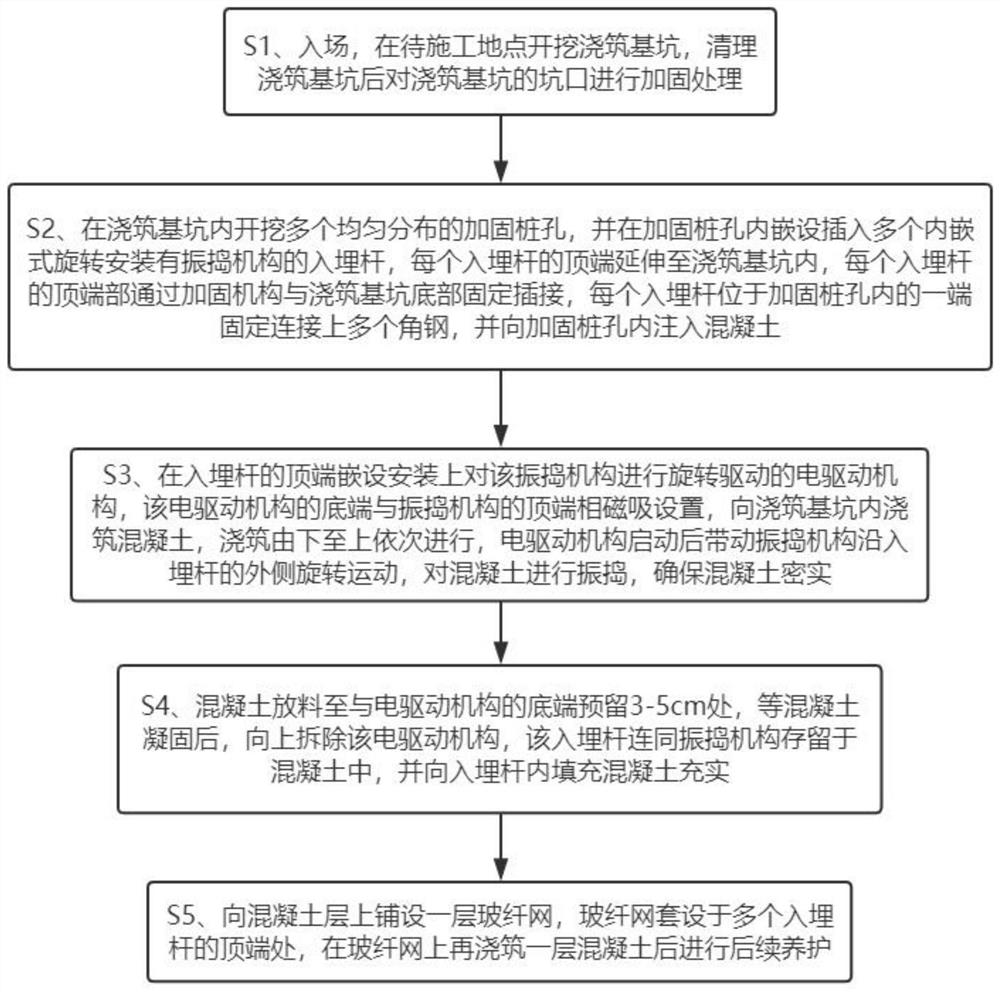

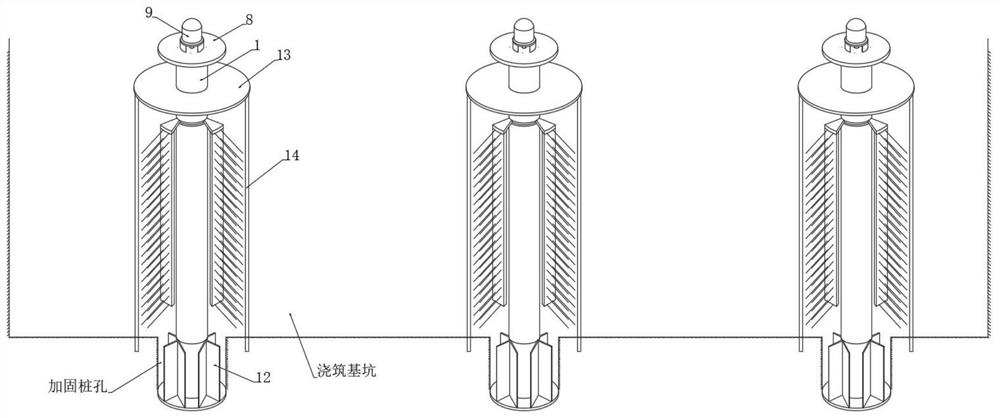

[0041] see Figure 1-2 , a concrete pouring process with internal vibration, the specific pouring steps are as follows:

[0042] S1. Entering the site, excavating and pouring foundation pits at the site to be constructed, and reinforcing the mouth of the pouring foundation pits after cleaning the pouring foundation pits;

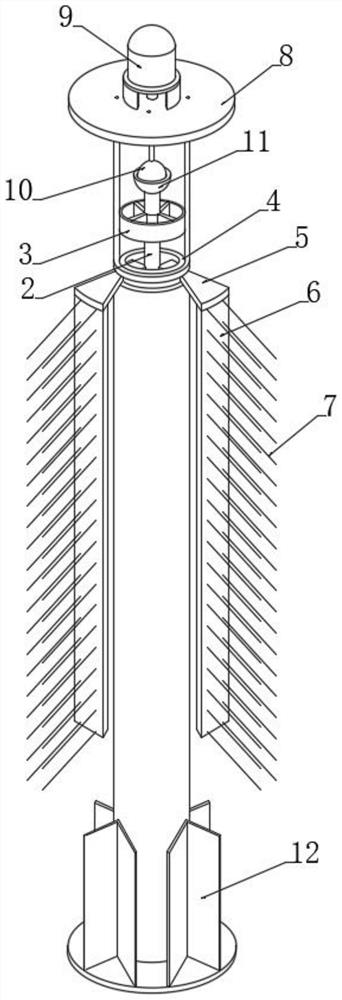

[0043] S2. Excavate a plurality of uniformly distributed reinforcement pile holes in the pouring foundation pit, and insert a plurality of embedded rods 1 with a vibrating mechanism installed in the reinforcement pile holes, and each embedded rod 1 The top end extends into the pouring foundation pit, and the top end of each embedded rod 1 is fixedly inserted into the bottom of the pouring foundation pit through a reinforcement mechanism. One end of each embedded rod 1 located in the reinforcement pile hole is fixedly connected to a plurality of angle steels 12, and Inject concrete into the reinforced pile hole;

[0044] S3. An electric drive mechanism for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com