Concrete internal vibration type pouring process

A technology of concrete inside and concrete, which is applied in construction, foundation structure engineering, sheet pile walls, etc., and can solve problems such as inconvenient manual manipulation, low work efficiency, and poor concrete vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

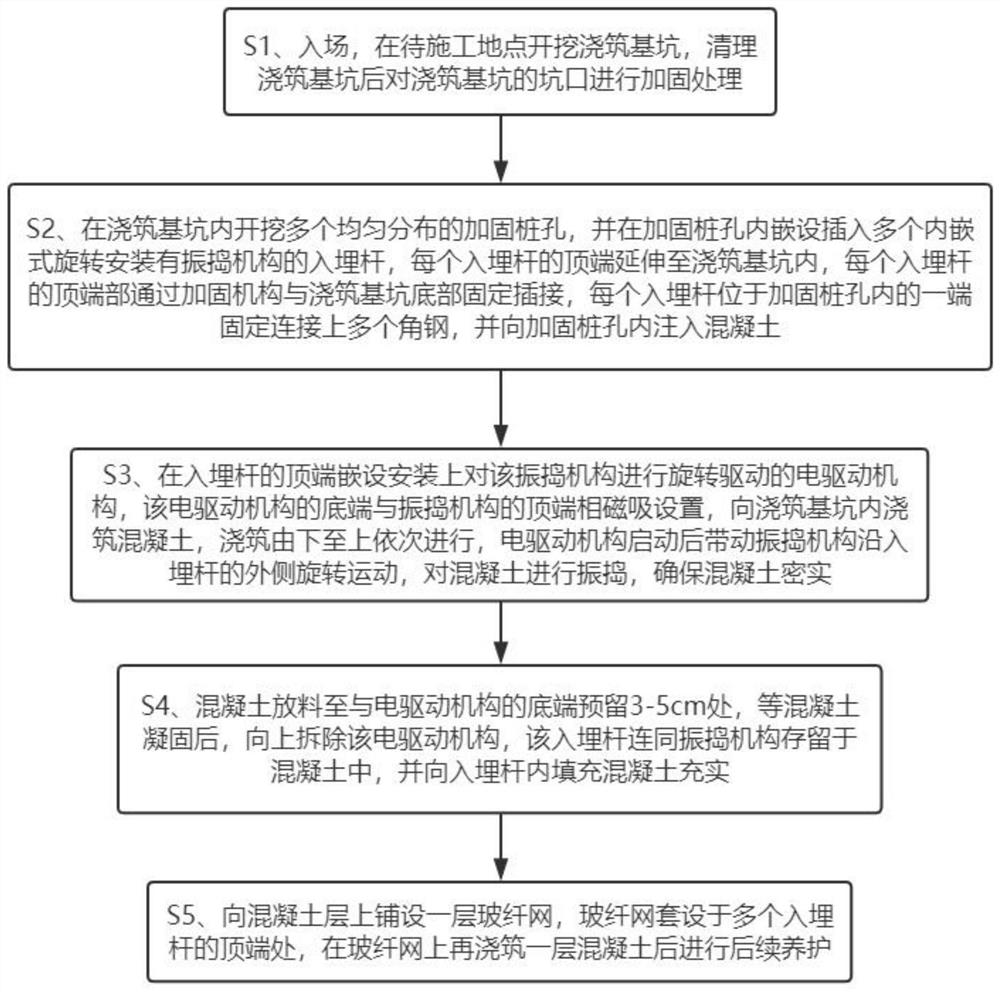

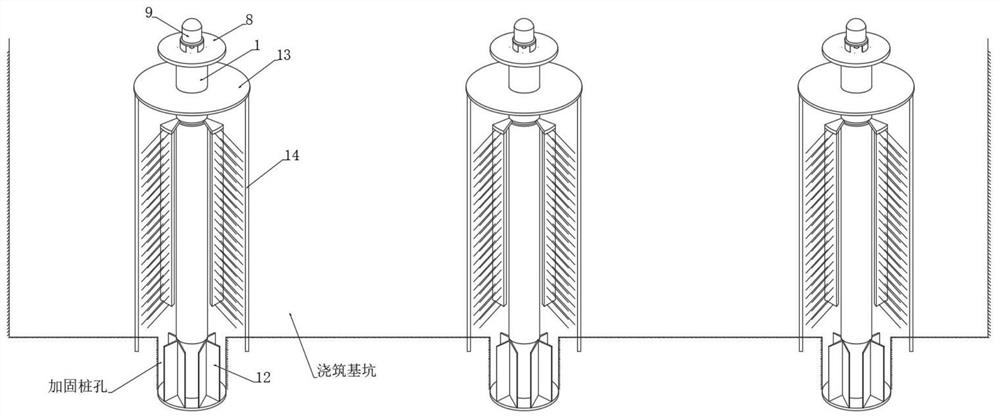

[0041] see Figure 1-2 , a concrete pouring process with internal vibration, the specific pouring steps are as follows:

[0042] S1. Entering the site, excavating and pouring foundation pits at the site to be constructed, and reinforcing the mouth of the pouring foundation pits after cleaning the pouring foundation pits;

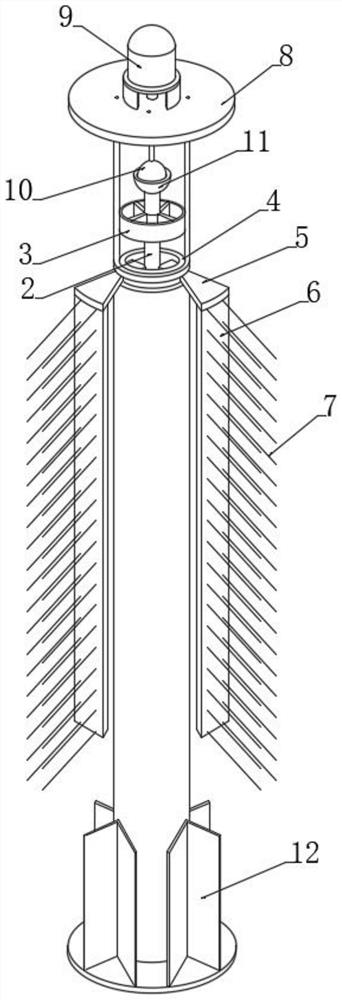

[0043] S2. Excavate a plurality of uniformly distributed reinforcement pile holes in the pouring foundation pit, and insert a plurality of embedded rods 1 with a vibrating mechanism installed in the reinforcement pile holes, and each embedded rod 1 The top end extends into the pouring foundation pit, and the top end of each embedded rod 1 is fixedly inserted into the bottom of the pouring foundation pit through a reinforcement mechanism. One end of each embedded rod 1 located in the reinforcement pile hole is fixedly connected to a plurality of angle steels 12, and Inject concrete into the reinforced pile hole;

[0044] S3. An electric drive mechanism for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com