Low-elasticity polyester yarn acid-alkali-resistant treatment device for textile fabrics

A technology for textile fabrics and processing devices, which is applied in the processing of textile materials, liquid/gas/steam processing transmission devices, and processing textile material drums, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

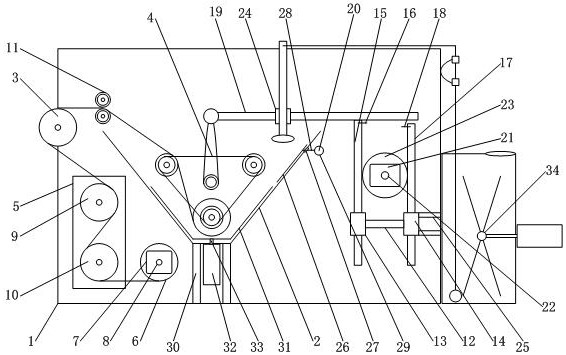

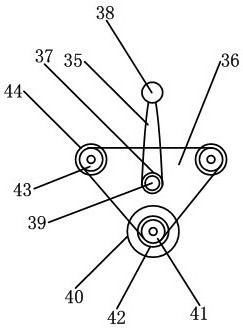

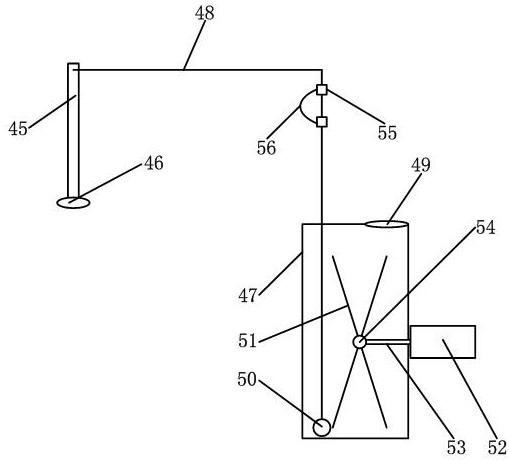

[0021] Such as Figure 1 to Figure 3 As shown, the anti-acid and alkali treatment device for low-elastic polyester yarn for textile fabrics includes a frame 1. An acid-base anti-acid treatment pool 2 is arranged inside the frame 1. The top of the anti-acid and alkali treatment pool 2 is an open structure, which is anti-acid and alkali One side of the treatment pool 2 is provided with a traction drum 3, the inside of the frame 1 is provided with a dipping and unwinding mechanism 4, the inside of the frame 1 is provided with an oven 5, and the bottom of the frame 1 is provided with a winding drum 6, and the frame 1 The bottom side wall position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com