LED soft light strip winding machine

A technology of winder and light strip, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of low manual winding efficiency and low safety factor, and achieve fast winding operation and work efficiency. High, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

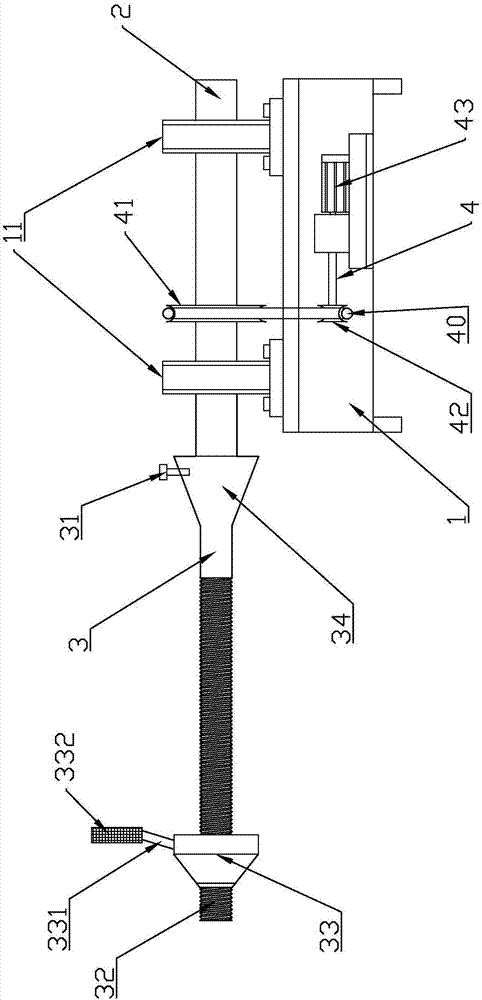

[0012] like figure 1 Shown is the structural diagram of the preferred embodiment provided by the present invention. In this embodiment, an LED flexible light belt winding machine includes a base 1. A rotating seat 11 and two rotating seats 11 are respectively arranged on the two ends of the base 1. A rotating shaft 2 is pierced between them. One end of the rotating shaft 2 is equipped with an installation shaft 3 for fixing the reel, and the other end is connected to the power mechanism 4. The installation shaft 3 can adjust the relative position along the rotation shaft 2 axially. The joint of the rotating shaft 2 is provided with a locking structure 31, which can be used to adjust the balance of the overall structure of the winder; the end of the installation shaft 3 away from the rotating shaft 2 is provided with an adjusting thread 32, and the adjusting thread 32 is adjustable and installed with a locking block 33. Can adapt to different roll specifications. In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com