Double-filament double-strand thread, fabric made of the double-filament double-strand thread, and production method thereof

A double-strand thread and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of insufficient yarn strength, poor fabric softness, and high difficulty in production of nylon and cotton spinning. low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

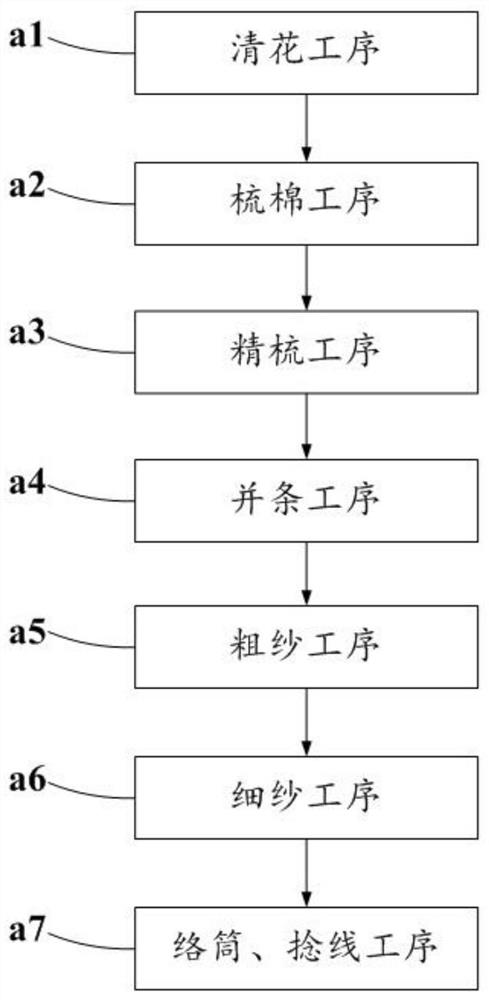

[0052] This embodiment provides a double-wire double-stranded wire, which includes the following steps:

[0053] Blowing process: the descending speed of the cotton picker beater is 3mm each time, the speed is 960r / min, the speed of the rotary trolley is 2.8r / min, the blade extends out of the rib 3mm, the beater speed is 800r / min, the fan speed is 950r / min, the beater and The gauge of the balance roller is 12mm, the rotation speed of the lap roller is 12r / min; the dry weight of the long-staple cotton fiber raw material is 350g / m, and the length of the lap is 36.5m.

[0054] Carding process: The distance between the cylinder and the licker-in of the carding machine is 7 inches, the distance between the feeder and the licker-in is 20 inches, the distance between the cylinder and the doffer is 4 inches, and the distance between the cylinder and the cover plate is 5 inches. It is 10 inches x 9 inches x 8 inches x 8 inches x 9 inches, the height of the dust removal knife is flat wi...

Embodiment 2

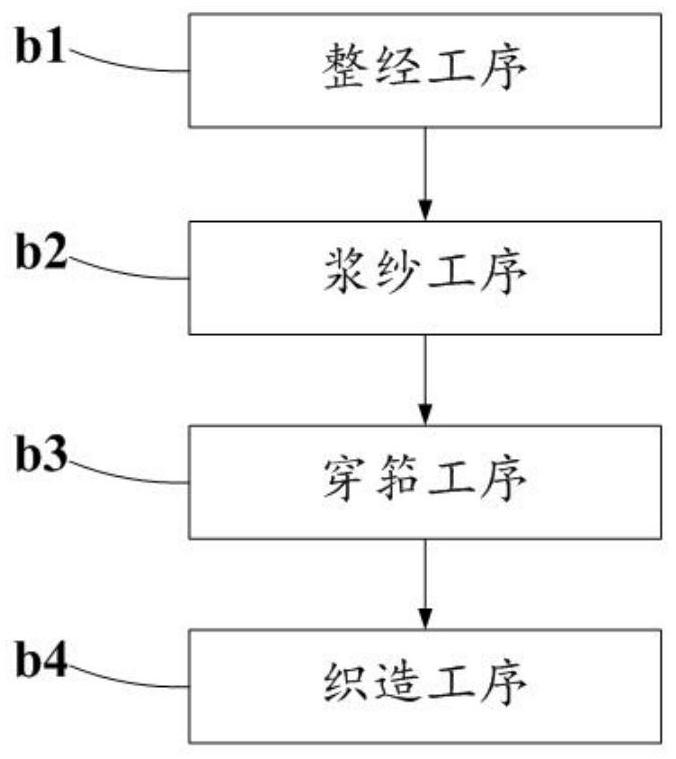

[0062] The present embodiment provides a winter training wear fabric, which is woven from the above-mentioned double-filament double-strand thread and conductive silk, and specifically includes the following steps:

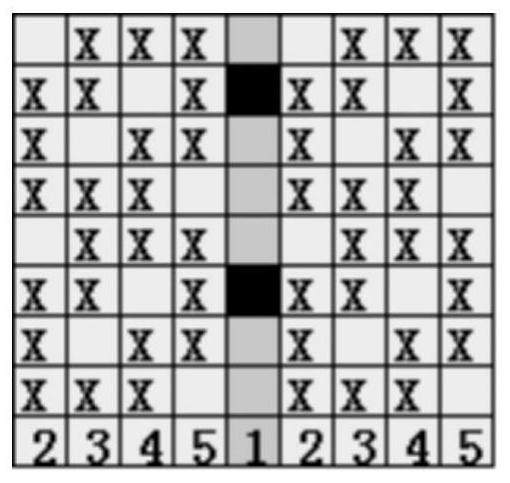

[0063] Warping process: KY6021 batch warping machine produced by Jiangyin Kaiyuan Textile Machinery Factory is used for warping. The number of warp yarn a is 5200, and the number of warp b is 80; the number of warp yarns is 4620 warp yarns a, the number of upper rows * the number of beams = 660 * 7; 580 warp yarns a and b are reserved for mixed warping to make a warp beam. During mixed warping, the creel is first loaded with warp yarn a, introduced into the telescopic reed, and then laid out evenly, then loaded with warp yarn b, introduced into the telescopic reed, and then laid out again. The beam width is 1753mm, and the warping speed is 500m / min.

[0064] Sizing process: Sizing formulation: Sizing is prepared from the following raw materials by mass percentage...

Embodiment 3

[0071] The present embodiment provides a fabric for summer training wear, which is woven from the above-mentioned double-strand core-wrapped yarn and conductive silk, and specifically includes the following steps:

[0072] a. Warping process: The KY6021 batch warping machine produced by Jiangyin Kaiyuan Textile Machinery Factory is used for warping. The number of warp yarn a is 3652, and the number of warp b is 80; the number of warping heads is 3110 For a warp yarn a, the number of upper rows * the number of warp beams = 622 * 5; 542 warp yarns a and warp b are reserved for mixed warping to make a warp beam. During mixed warping, the creel is first loaded with warp yarn a, introduced into the telescopic reed, and then laid out evenly, then loaded with warp yarn b, introduced into the telescopic reed, and then laid out again. The beam width is 1846mm, and the warping speed is 500m / min.

[0073] b. Sizing process: The sizing formula and sizing process are the same as those for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com