Preparation method of water-based dyeing auxiliary agent for synthetic leather

A technology for dyeing auxiliaries and synthetic leather, applied in the field of dyeing, can solve problems such as poor dyeing performance of oily polyurethane resin, and achieve the effects of reducing usage, reducing sealing cost and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

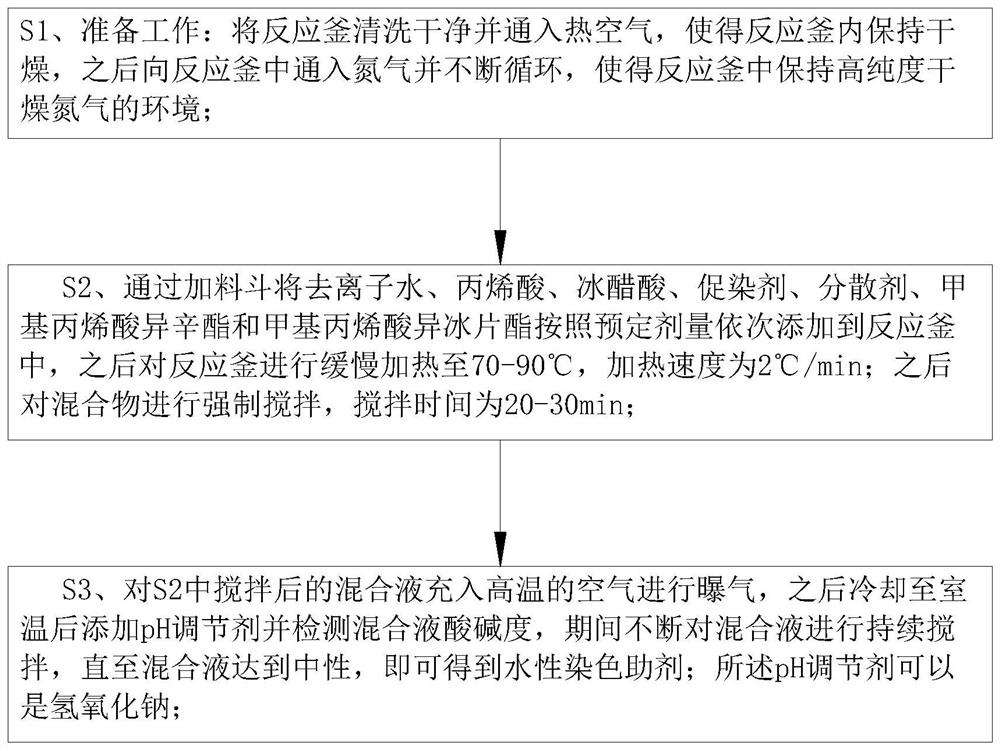

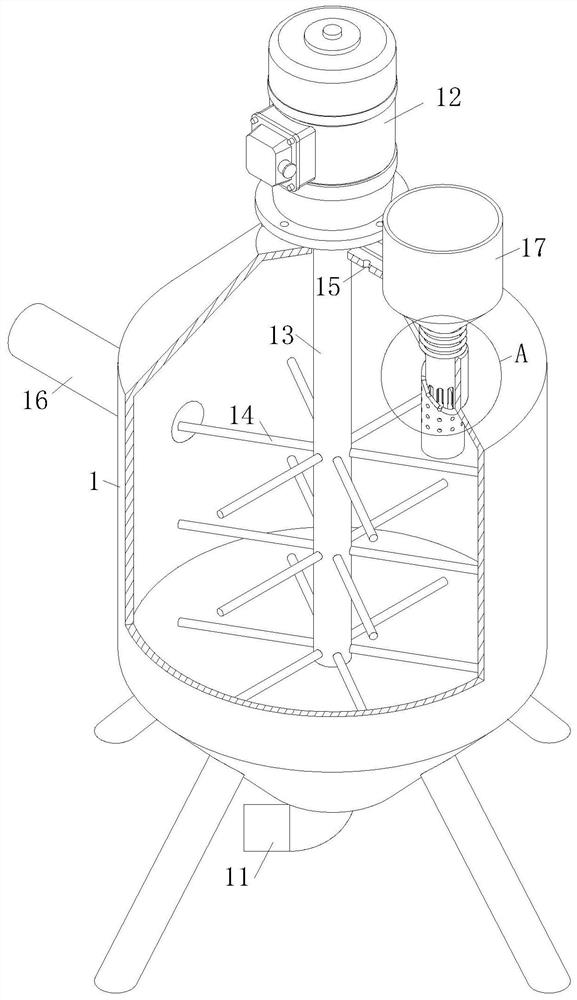

[0028] Such as Figure 1 to Figure 6 Shown, the preparation method of a kind of synthetic leather aqueous dyeing auxiliaries of the present invention comprises the following steps:

[0029] S1. Preparatory work: clean the reactor and pass hot air into it to keep the inside of the reactor dry, then feed nitrogen into the reactor and circulate continuously so that the environment of high-purity dry nitrogen is maintained in the reactor;

[0030] S2. Add deionized water, acrylic acid, glacial acetic acid, dye accelerator, dispersant, isooctyl methacrylate and isobornyl methacrylate into the reactor in sequence according to the predetermined dosage through the hopper, and then carry out the reaction on the reactor Slowly heat to 70-90°C with a heating rate of 2°C / min; then forcefully stir the mixture for 20-30min;

[0031] S3. Fill the mixed solution stirred in S2 into high-temperature air for aeration, then add a pH regulator after cooling to room temperature and detect the pH o...

Embodiment approach

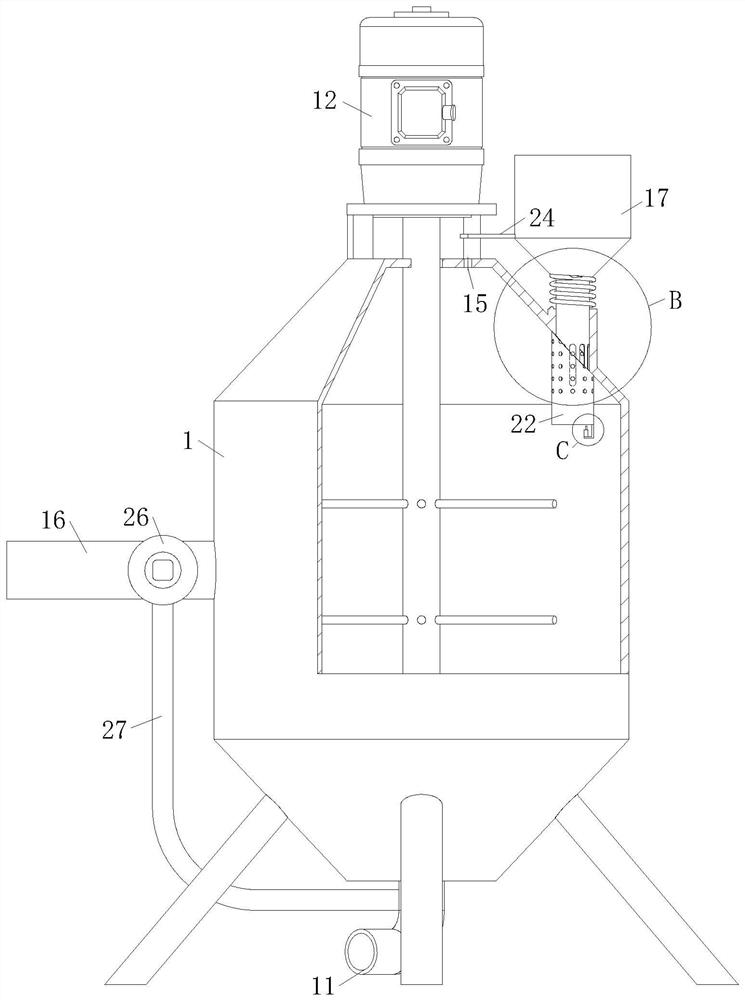

[0034] As an embodiment of the present invention, a sleeve 22 is fixedly connected to the corresponding position of the feed pipe 16 in the body 1, the sleeve 22 runs through the body 1, and the feed pipe 16 is sleeved inside the sleeve 22 and connected to the sleeve 22. Sliding connection; a spring is sleeved on the feed pipe 16 between the top of the sleeve 22 and the feed hopper 17; a group of No. 2 holes 23 are provided on the sleeve 22 corresponding to the No. 1 hole 2, and the feeding After the pipe 16 slides down, the No. 1 hole 2 is disconnected from the No. 2 hole 23; the side of the feed hopper 17 is fixedly connected to the position corresponding to the vent hole 15 with a sealing plate 24, and the sealing plate 24 is used to close the vent hole after falling. 15. After the feed pipe 16 slides down, the nitrogen in the body 1 is discharged through the feed pipe 16, further improving the purity of the nitrogen in the body 1; when the feed hopper 17 is filled with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com