Organic silicon extrusion device

An extrusion device and organosilicon technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems that liquid silicone cannot be discharged when solidified, and does not have an anti-solidification function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

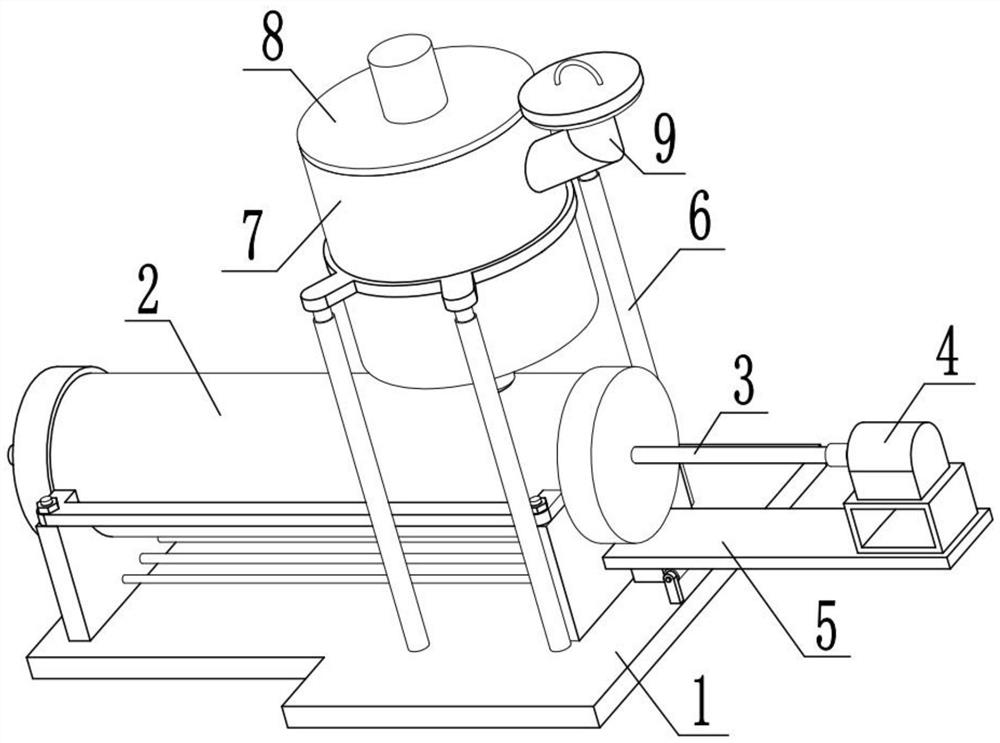

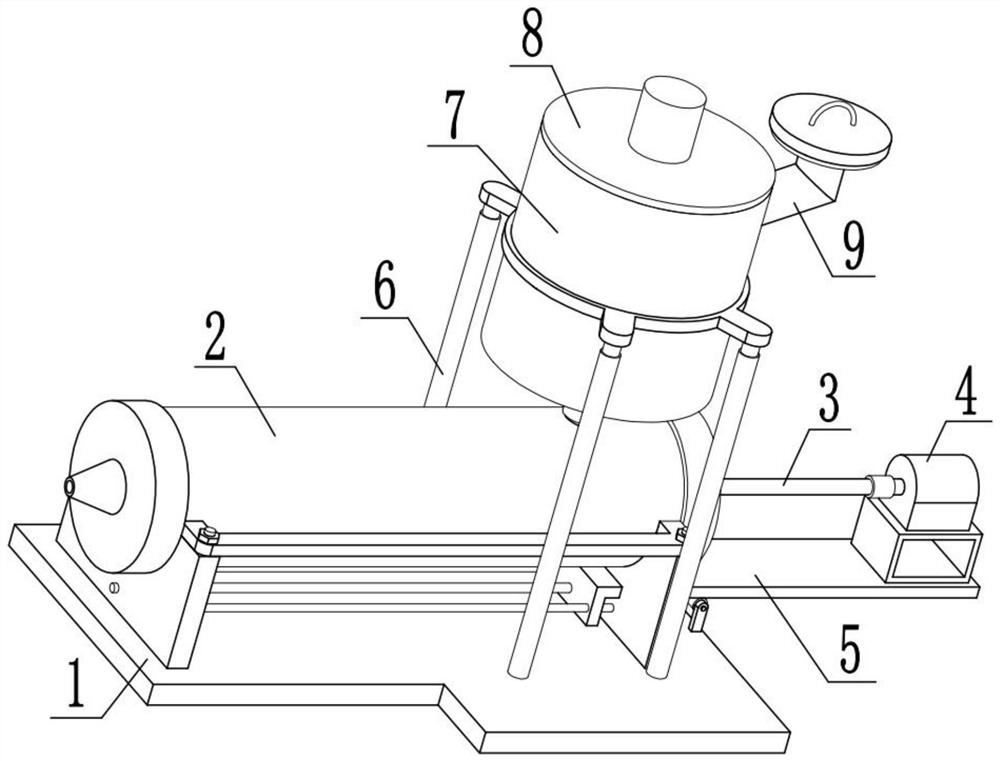

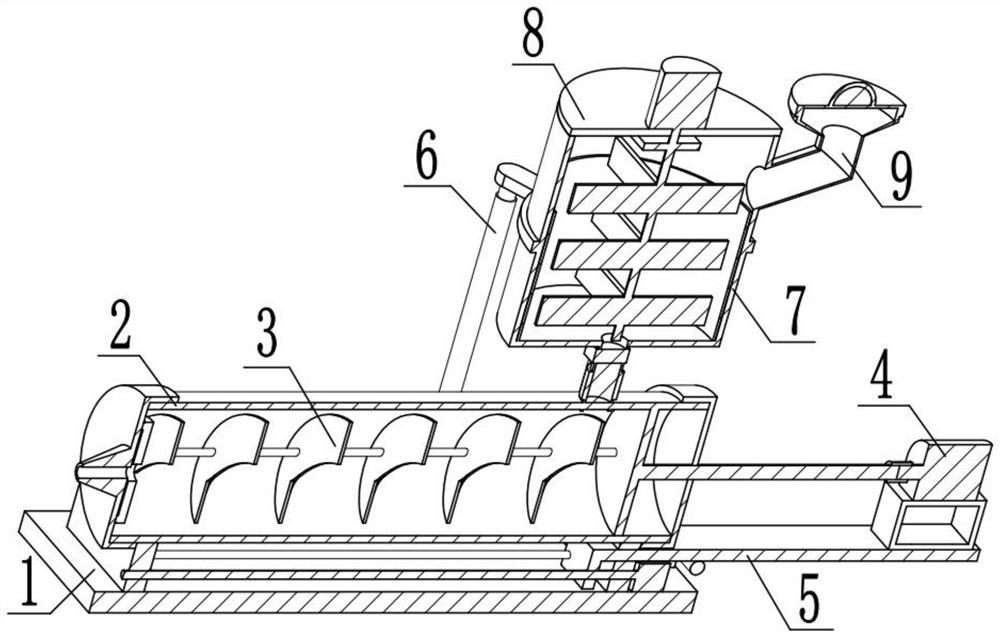

[0032] Combine below Figure 1-13 To illustrate this embodiment, the present invention relates to the field of silicone technology, more specifically, a silicone extrusion device, including an extrusion bearing fixture 1, a silicone storage device 2, a stirring extrusion device 3, and a stirring power device 4 , the sliding linkage device 5, the lifting support bracket body 6, the solid silicon melting barrel 7, the shielding stirring device 8 and the solid silicon adding port 9, the fixed silicone is added to the processing barrel 7-1 through the transfer inclined pipe 9-1, Start the heating ring 7-3 to heat the solid silicone and a plurality of stirring plates 8-4 to stir the solid silicone. When the solid silicone turns into liquid silicone, the liquid silicone is passed through the drain pipe 7-5 and feed pipe 2-6 into the storage cavity 2-1, start the motor II4-1 to drive the extrusion slide plate 3-1, the fixed plate 3-3 and the elastic spiral plate 3-4 to rotate, at thi...

specific Embodiment approach 2

[0035] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1. The extrusion load-bearing fixing frame 1 includes a fixed bottom plate 1-1, a support seat 1-2, a fixed sliding column 1-3, a fixed nut 1-4, a limiter Position sliding column 1-5, lead screw 1-6, motor I1-7, bearing seat 1-8 and rolling rod 1-9, fixed base plate 1-1 plays the role of bearing and fixing, and the left and right sides above the fixed base plate 1-1 Both ends are fixedly connected with support bases 1-2, and the two support bases 1-2 can provide a fixed support space for the storage cavity 2-1, and the front and rear ends above each support base 1-2 are fixedly connected with fixed support bases 1-2. Sliding column 1-3, fixed sliding column 1-3 can provide sliding space for two support handles 2-2, and each fixed sliding column 1-3 is connected with fixing nut 1-4 by thread, utilizes fixing nut 1 -4 The two support handles 2-2 are fixed, and there are t...

specific Embodiment approach 3

[0037] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the second embodiment, the silicone storage device 2 includes a storage cavity 2-1, a support handle 2-2, a shielding cap I2-3, a shielding cap II2-4, The extrusion port 2-5 and the feed pipe 2-6, the storage cavity 2-1 is a hollow structure to facilitate the storage of liquid silicone, and the front and rear ends of the storage cavity 2-1 are fixedly connected with support handles 2-2, Use two support handles 2-2 to fix the storage cavity 2-1. After the four fixing nuts 1-4 are disassembled, the storage cavity 2-1 can be disassembled. At this time, the silicone Squeeze to the correct position, the two support handles 2-2 are respectively slidably connected with the four fixed sliding columns 1-3, the four fixed nuts 1-4 are respectively in contact with the two support handles 2-2, and the storage cavity 2- The two ends of 1 are connected with shielding cap I2-3 and shielding cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com