An auxiliary clamping and fixing device for grinding and polishing of special complex casting parts

A technology of casting parts, clamping and fixing, applied in the field of parts processing, can solve the problems of poor stability of connecting parts, easy scattering of metal chips, affecting the cleanliness of the surrounding processing environment, etc., to ensure stability, reduce rotational friction coefficient, The effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

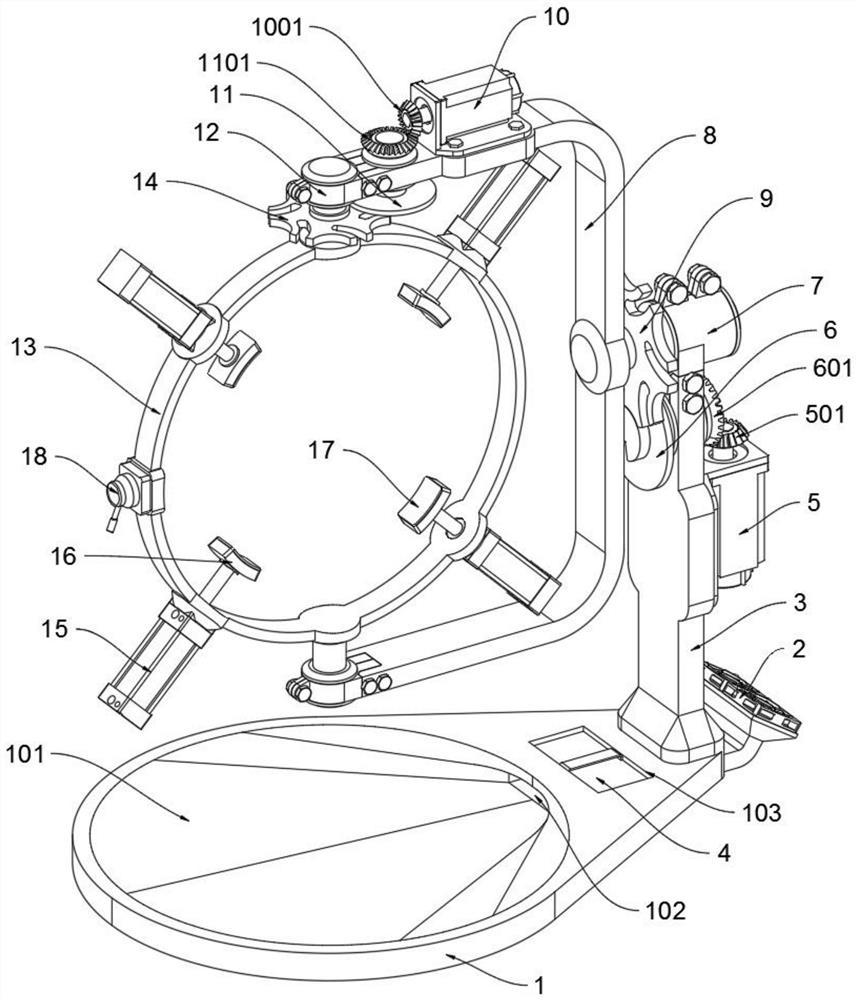

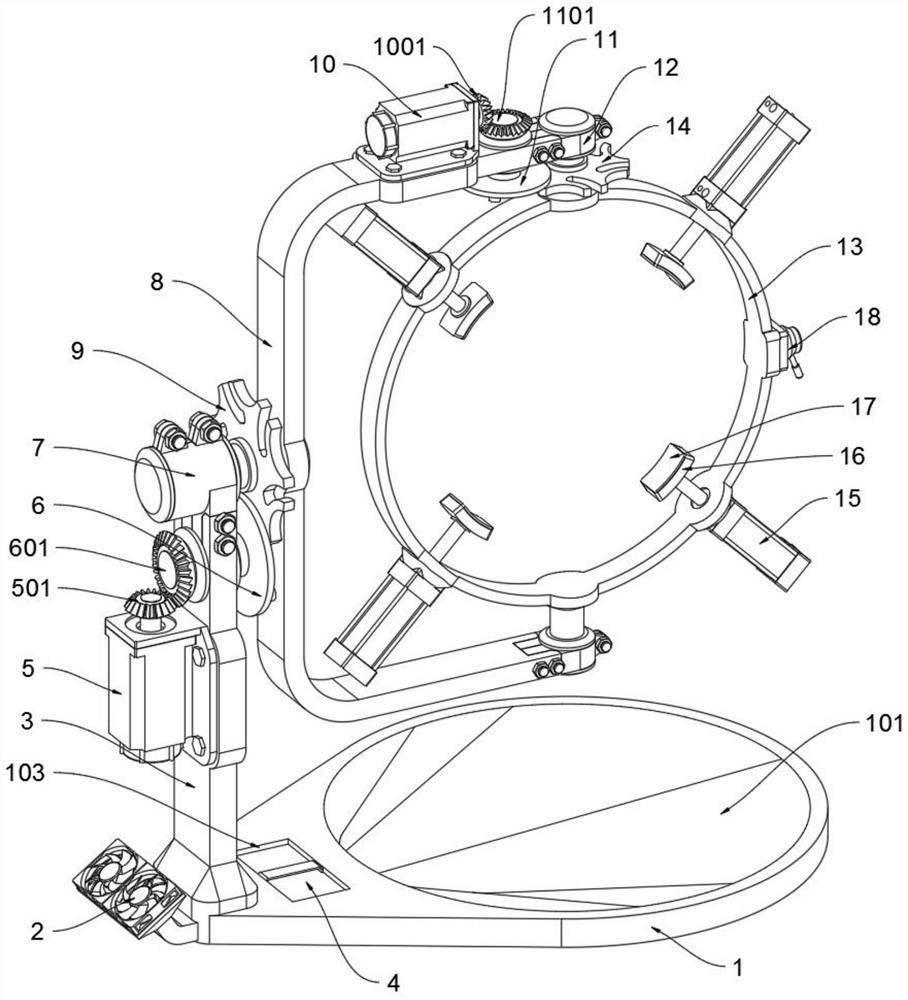

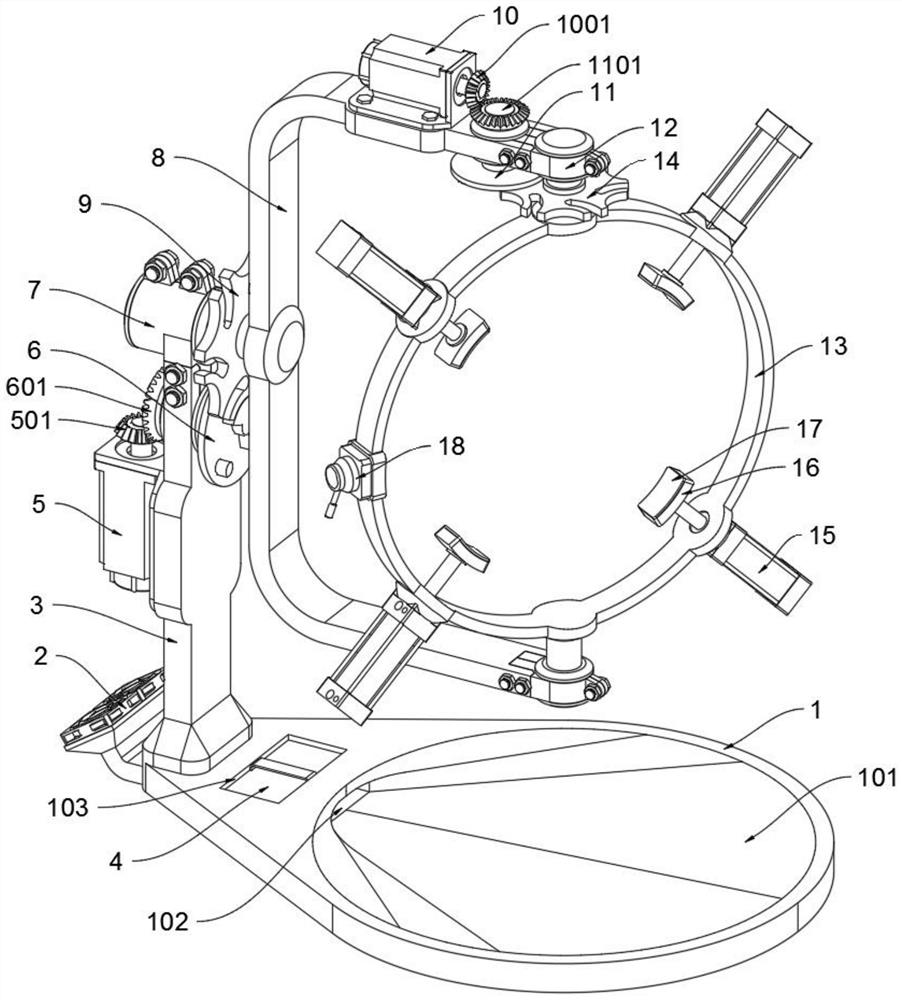

[0032] as attached figure 1 To attach Figure 8 Shown:

[0033]The invention provides an auxiliary clamping and fixing device for grinding and polishing of special complex casting parts, which includes a base 1, a fan 2, a support column 3, a driving motor 10 and an air control valve 18; 101, and the filter box 4 is placed inside the base 1; the fan 2 has two places, the fan 2 is installed on the rear end of the base 1, and the fan 2 is connected to the control circuit; the support column 3 is installed on the top of the rear end of the base 1, and the transmission motor 5 Installed on the rear end face of the support column 3, and a driving gear A501 is installed on the rotating shaft of the transmission motor 5; the transmission motor 5 is connected to the driven sheave A9 through the driving dial A6, and the transmission motor 5 is connected to the control circuit; the support column 3. The top is connected to the support frame 8 through the main connector 7; the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com