A production device and process for inner bobbin castings

A production device and bobbin technology, which is applied in the direction of grinding drive devices, manufacturing tools, metal processing equipment, etc., can solve the problems of labor-intensive, time-consuming and labor-intensive, and difficult to fix, so as to reduce labor costs, facilitate use, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

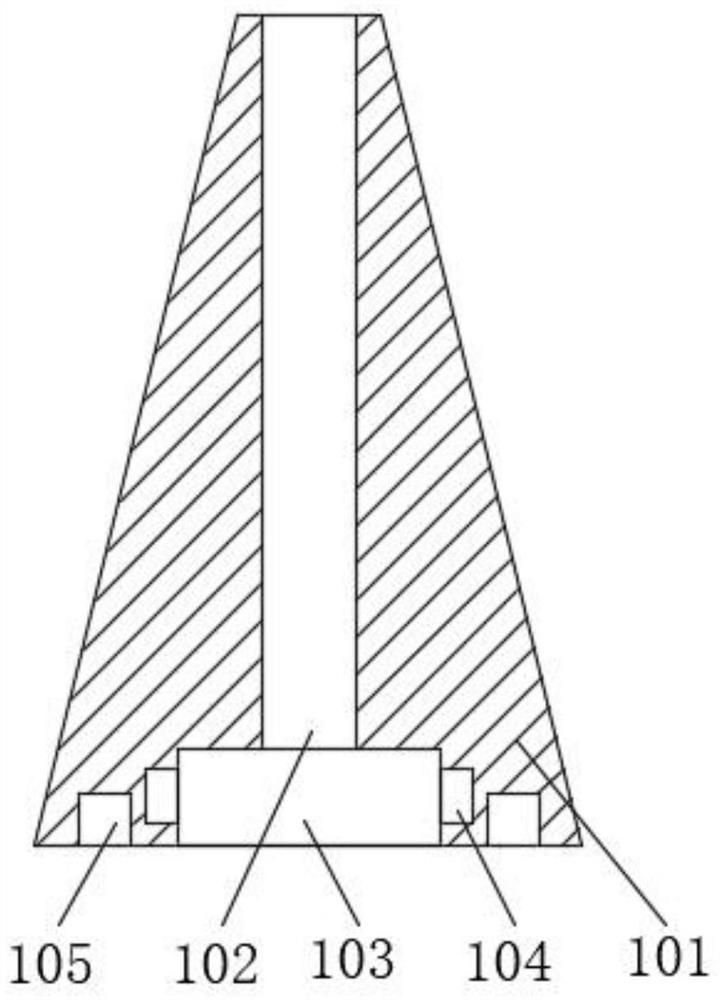

[0048] see figure 1 and image 3 , an inner bobbin casting production device, including a bobbin 1 and a grinding mechanism, the bobbin 1 includes a barrel body 101, a middle hole 102, a connecting groove 103, a card groove 104, a positioning groove 105, and the middle part of the barrel body 101 A middle hole 102 is opened, and the bottom end of the middle hole 102 is provided with a connection groove 103, and both sides of the connection groove 103 are provided with a card groove 104, and two positioning grooves 105 are provided on the outer wall of the bottom end of the cylinder body 101, and the positioning groove 105 Located on a side of the locking groove 104 away from the connecting groove 103 , the connecting groove 103 runs through the bottom outer wall of the barrel 101 .

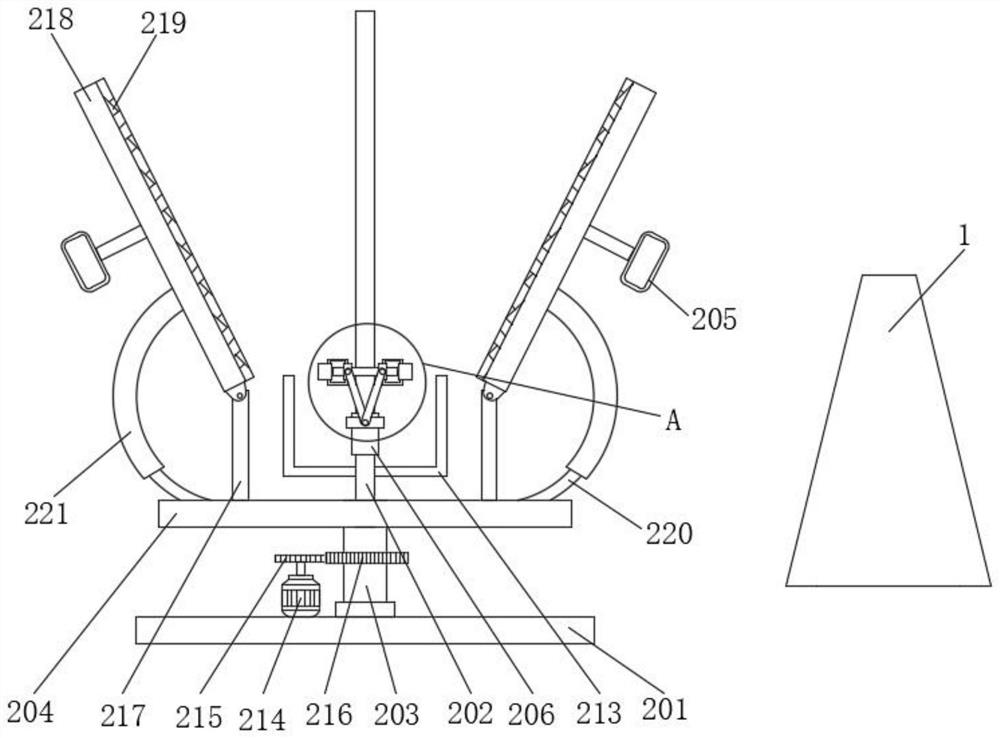

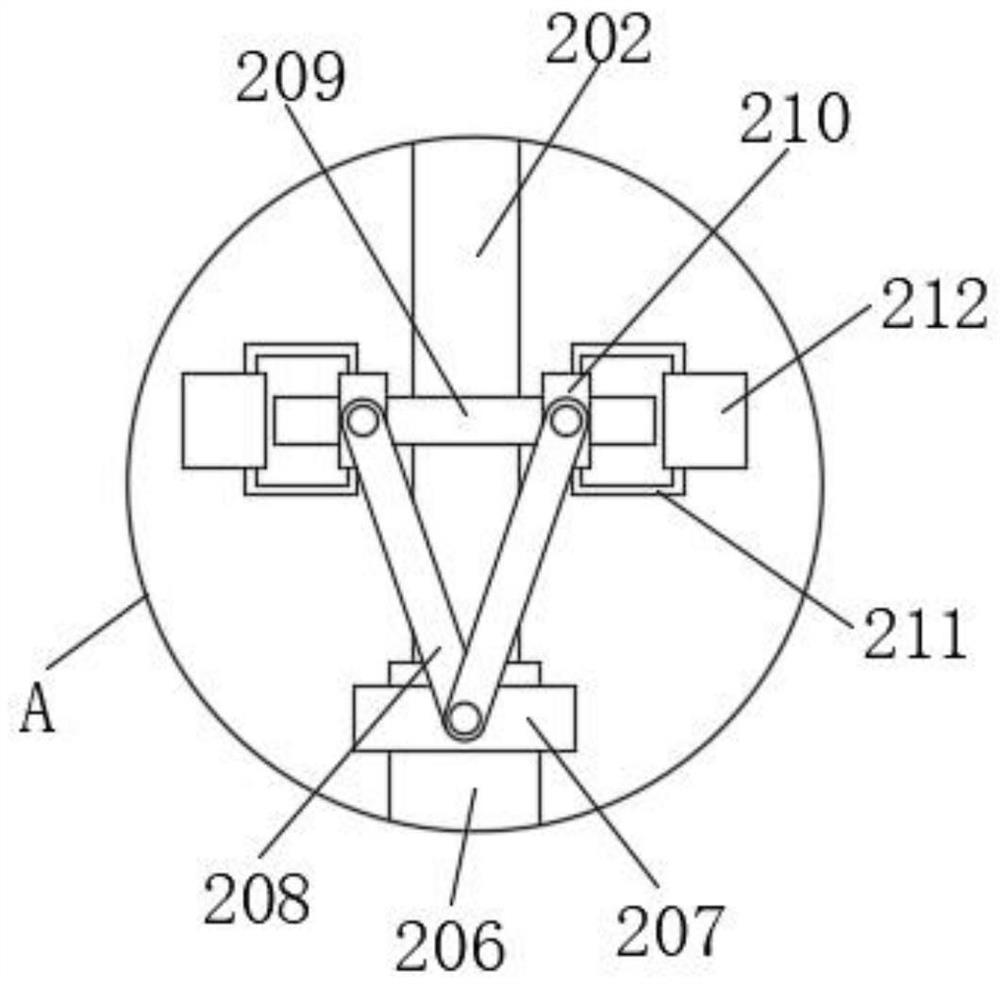

[0049] see Figure 1-2 and Figure 4-7 , the grinding mechanism includes a device base 201, a middle rod 202, a sleeve rod 203, a support plate 204, a handle 205, an adjustment cylinder 206, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com