Round steel reducing and oil brushing mechanism, round steel reducing device and using method of round steel reducing device

A round steel and diameter reduction technology, which is applied to the device for coating liquid on the surface, metal processing equipment, forming tools, etc., can solve the problems of affecting the quality of the round steel, unfavorable round steel diameter reduction efficiency, and taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

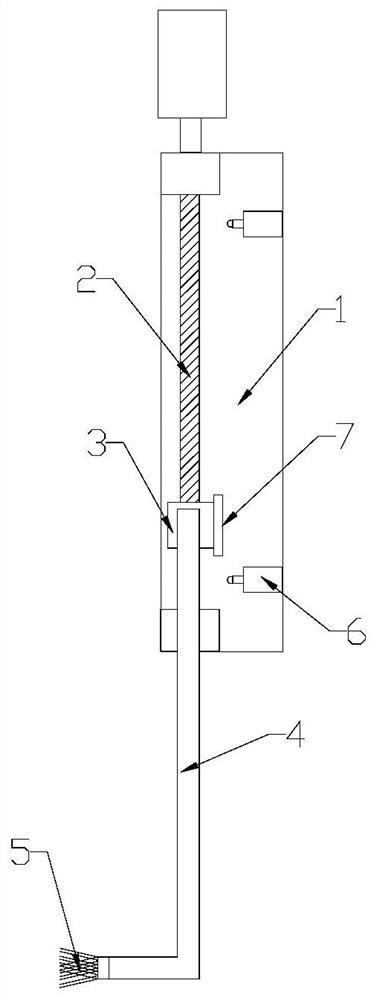

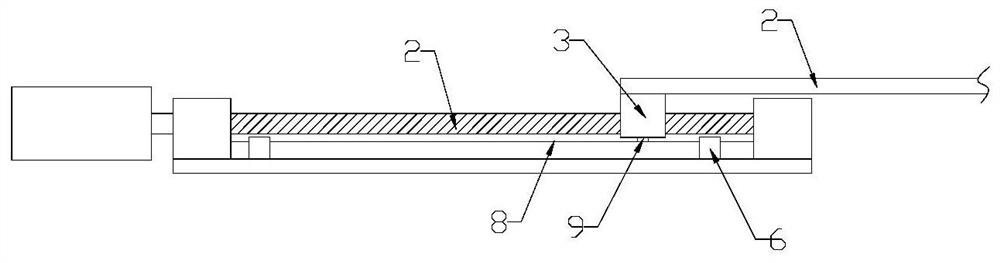

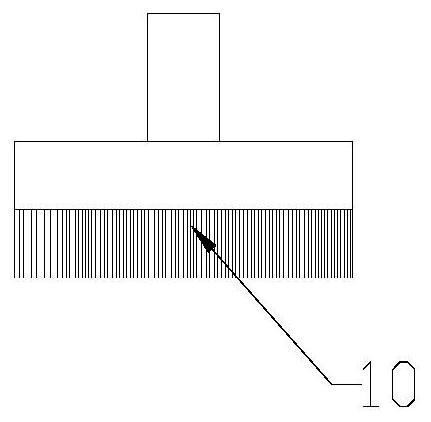

[0032] Such as Figure 1-3 As shown, a round steel shrinkage brushing mechanism includes a bottom plate 1, on which a transmission screw 2 driven by a deceleration motor is arranged, on which a sliding seat 3 is arranged, and the sliding seat 3 is connected with an L-shaped connecting rod 4 connected, the end of the L-shaped connecting rod 4 away from the sliding seat 3 is fixed with a brush 5, and the bottom plate 1 at both ends of the transmission screw 2 is provided with a travel switch 6, the travel switch 6 is a swing arm type travel switch 6, and the sliding seat 3 A positioning rod 7 cooperating with the travel switch 6 is provided on the top, a chute 8 parallel to the transmission screw 2 is provided on the bottom plate 1, a guide rod 9 placed in the chute 8 is provided on the slide seat 3, and the guide rod 9 is arranged along the The chute 8 moves, and the hairbrush 5 is a flat brush 10.

[0033] The usage method of this embodiment: install the bottom plate 1 above ...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 4As shown, the hairbrush 5 is a ring brush 11, and the ring brush 11 includes a semicircular fixed brush body 12. The fixed brush body 12 opens upward and is connected with the L-shaped connecting rod 4. The two upper ends of the fixed brush body 12 are Both sides are hinged with arc-shaped movable brush bodies 13 by rotating shafts, torsion springs are sleeved on the rotating shafts, and the fixed brush body 12 and two movable brush bodies 13 form a ring.

[0036] The use method of this embodiment: the sliding seat 3 drives the ring brush 11 to move up to the travel switch 6 at the upper end through the L-shaped connecting rod 4, and the round steel passes through the inner ring of the ring brush 11 to complete the brushing of the reducing end of the round steel at one time. Finally, the L-shaped connecting rod 4 drives the ring brush 11 to move down, and the round steel pushes the two...

Embodiment 3

[0038] Such as Figure 5 As shown, a round steel diameter reduction device includes a body 14, an oil tank 15 with an upward opening is arranged on the body 14, and an axially movable diameter reduction mechanism is arranged on the body 14 on one side of the oil groove 15, and the diameter reduction mechanism and the The linear drive mechanism is connected, such as an axial hydraulic cylinder, etc., to control the reciprocating movement of the diameter reducing mechanism, and the body 14 on the other side is provided with an axial round steel support mechanism, and an embodiment The above-mentioned oil brushing mechanism, the brush 5 is a flat brush 10, the brush 5 is placed in the oil tank 15, the base is fixed on the body 14, and is located above the oil tank 15, and the transmission screw rod 2 is vertically installed on the base , The sliding seat 3 drives the brush 5 to move back and forth vertically.

[0039] Such as Figure 5-7 As shown, the diameter reduction mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com