Bismuth tungstate photocatalyst preparation device based on hydrodynamic cavitation and ultrasonic cavitation

A photocatalyst and preparation device technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of inefficient large-scale bismuth tungstate nanophotocatalyst industry Chemical production, many preparation steps, large shrinkage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

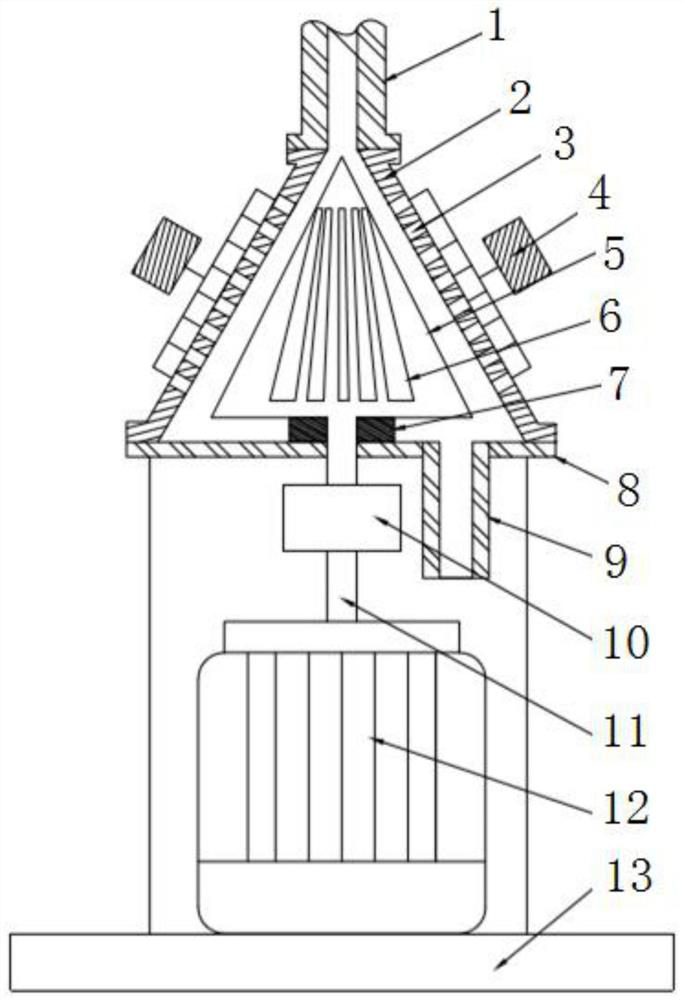

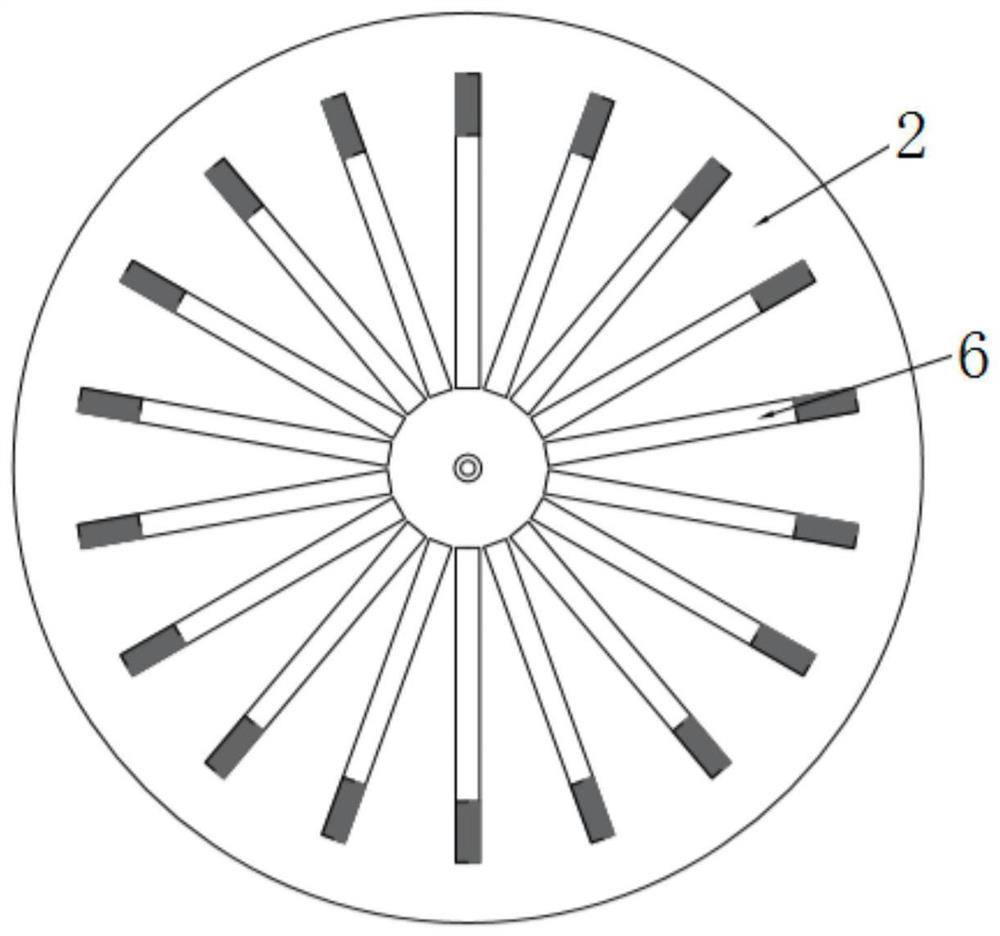

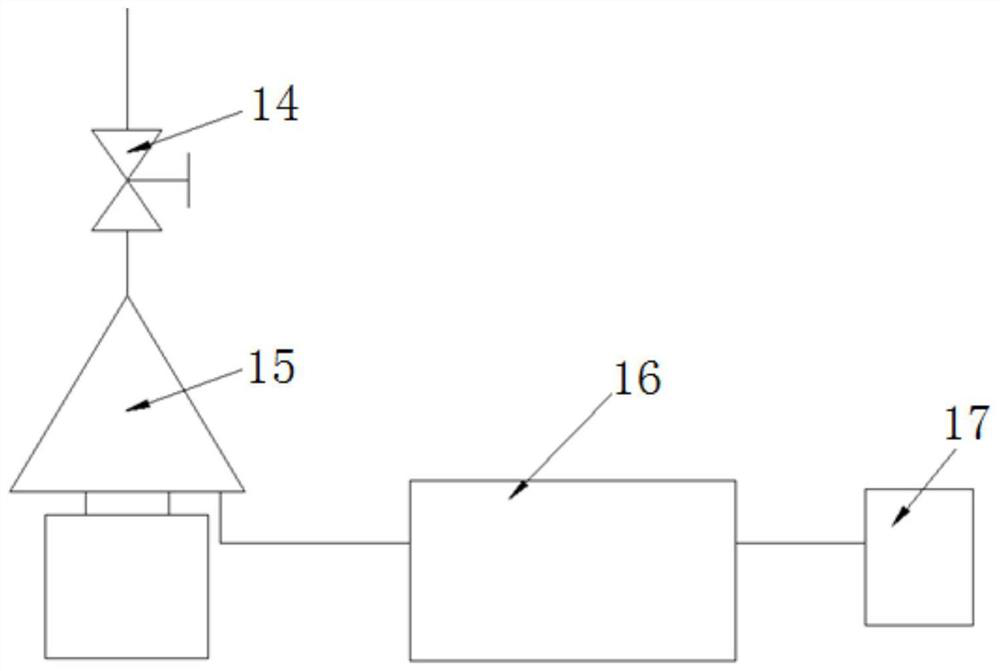

[0045] The structure of the bismuth tungstate photocatalyst preparation device 15 based on hydraulic cavitation and ultrasonic cavitation in the present invention is as follows figure 1 As shown, it includes a stator 2 , an ultrasonic transducer 3 , an ultrasonic generator 4 , a rotor 5 and a rotating shaft 11 . The stator 2 is a tapered airtight cavity, the bottom of the stator 2 is connected to the end cover 8 by bolts, and the bottom of the end cover 8 is supported on the base 13 . An ultrasonic transducer 3 is installed on the inner wall of the stator 2 . Each ultrasonic transducer 3 is connected to an ultrasonic generator 4 . The ultrasonic transducers 3 are embedded in the inner wall of the stator along the axial and circumferential directions in the form of 2 to 8 in each row, 2 to 6 rows in total, and equally spaced. The number of ultrasonic generators 4 is 1-4, the frequency is above 20kHz, and the power of a single machine is 1500-3000W. After coupling ultrasonic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com