Multi-level controllable assembly type fluorescent-magnetic bifunctional microsphere as well as preparation method and application thereof

An assembly-type, multi-level technology, applied in the preparation of microspheres, microcapsules, fluorescence/phosphorescence, etc., can solve the problems of uncontrollable size and poor chemical stability, and achieve high-efficiency co-assembly, good biocompatibility, and high efficiency. Performance without interfering with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Dendritic mesoporous silica microsphere template (dSiO 2 )Synthesis:

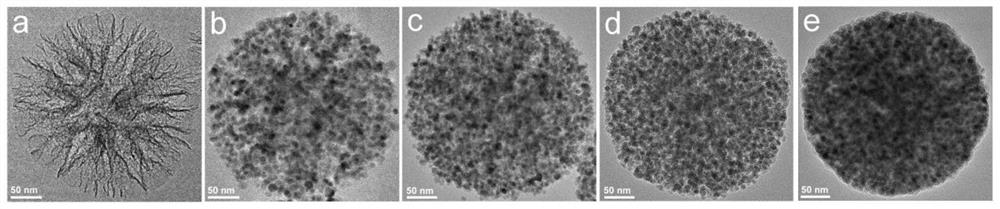

[0047] Add 0.136 g triethanolamine (TEA), 0.76 g cetyltrimethylammonium bromide (CTAB), 0.4632 g sodium salicylate (NaSal), and 8 mL tetraethylorthosilicate (TEOS) to 50 mL centrifuge the solution in ultrapure water, and react with magnetic force in an oil bath at 80 °C for 2 h, wash the precipitate with absolute ethanol, and repeat this step twice; finally, add the precipitate to a mixture of 100 mL hydrochloric acid and 100 mL methanol solution, and magnetically stirred for 6 h, then the product was washed three times with absolute ethanol and dispersed in 200 mL ethanol to obtain the product dSiO 2 , and its TEM image is shown in figure 1 As shown in a, it can be seen that dSiO 2 It has a very obvious center-radial channel, which can provide a large space for the subsequent loading of functional nanoparticles;

[0048] (2) Preparation of magnetic carrier SI (dendritic mesoporous silicon sp...

Embodiment 2

[0060] (1) Dendritic mesoporous silica microsphere template (dSiO 2 )Synthesis:

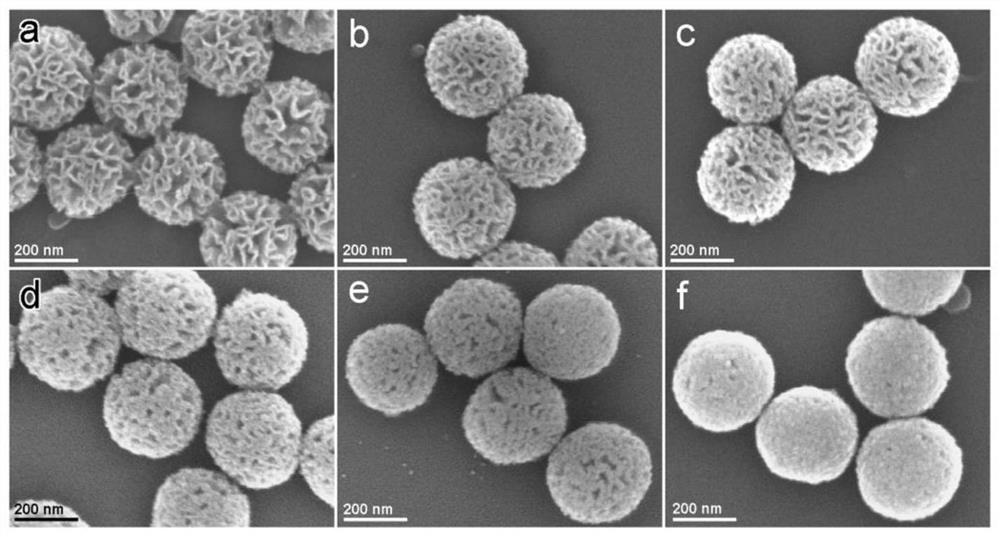

[0061] Add 0.272 g triethanolamine (TEA), 1.52 g cetyltrimethylammonium bromide (CTAB), 0.9264 g sodium salicylate (NaSal), and 16 mL tetraethylorthosilicate (TEOS) to 100 mL centrifuge the solution in ultra-pure water with magnetic stirring in an oil bath at 80 °C for 2 h, wash the precipitate with absolute ethanol, and repeat this step twice; finally add the precipitate to a mixture of 200 mL hydrochloric acid and 200 mL methanol solution, and magnetically stirred for 6 h, then the product was washed three times with absolute ethanol and dispersed in 400 mL ethanol to obtain the product dSiO 2 , its SEM image is shown in figure 2 As shown in a, it can be seen that the dendritic mesoporous silicon sphere has a pore size of tens of nanometers, and its inner surface is almost completely accessible, providing a large space for the loading of functional nanoparticles;

[0062] (2) Preparation of...

Embodiment 3

[0073] (1) Dendritic mesoporous silica microsphere template (dSiO 2 )Synthesis:

[0074] Add 0.136 g triethanolamine (TEA), 0.76 g cetyltrimethylammonium bromide (CTAB), 0.4632 g sodium salicylate (NaSal), and 8 mL tetraethylorthosilicate (TEOS) to 50 mL centrifuge the solution in ultra-pure water and react with magnetic force in an oil bath at 80 °C for 2 h, wash the precipitate with absolute ethanol, and repeat this step twice; finally add the precipitate to a mixture of 200 mL hydrochloric acid and 200 mL methanol solution, and magnetically stirred for 6 h, then the product was washed three times with absolute ethanol and dispersed in 400 mL ethanol to obtain the product dSiO 2 ;

[0075] (2) Preparation of magnetic carrier SI (dendritic mesoporous silicon sphere / ferric oxide nanoparticle composite microsphere):

[0076] Take 15 mL of the above product and centrifuge to keep the precipitate, add it together with 0.72 g of iron triacetylacetonate and 60 mL of triethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com